Market Overview

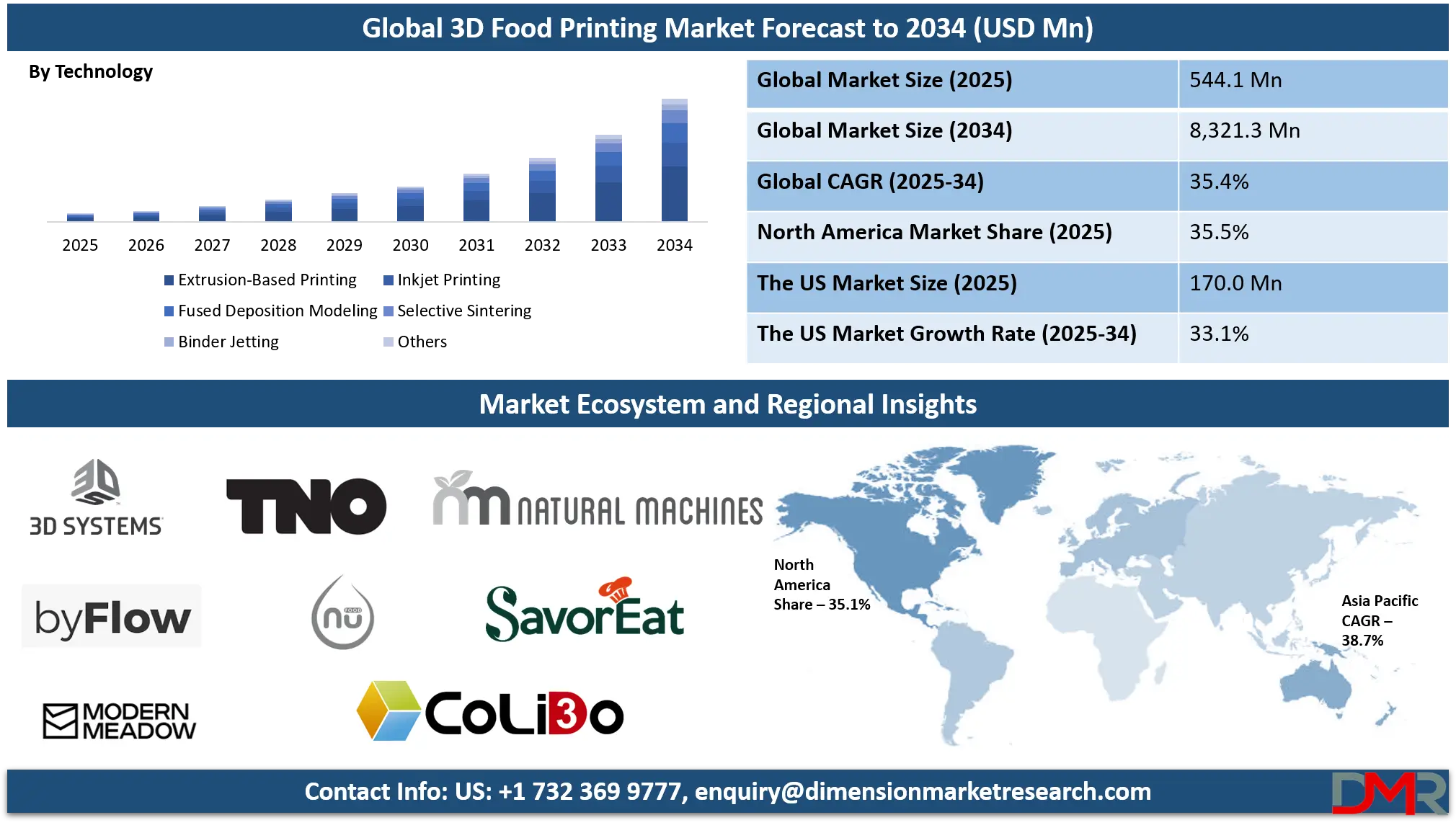

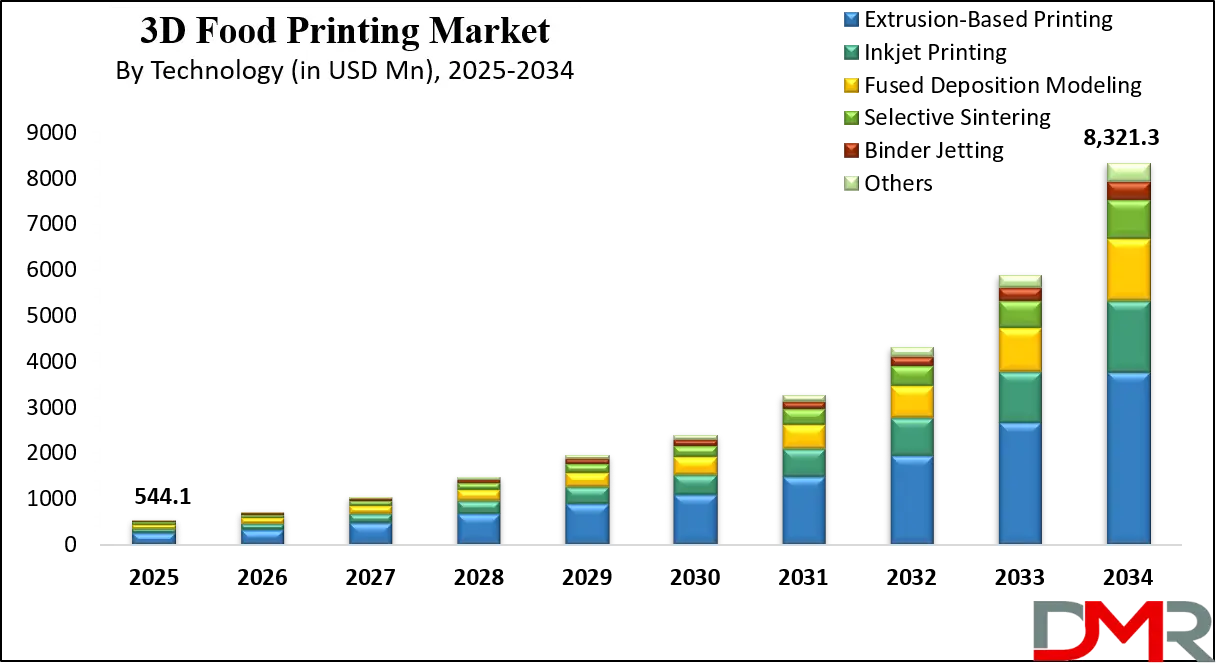

The Global 3D Food Printing Market size is projected to reach USD 544.1 million in 2025 and grow at a compound annual growth rate of 35.4% from there until 2034 to reach a value of USD 8321.3 million.

3D food printing is a new technology that uses machines to create food in different shapes and designs. It works by layering ingredients, much like how a normal 3D printer builds objects from plastic or metal. Instead of ink or plastic, the printer uses food pastes, purees, or dough to make items. These machines can be used to create fun shapes, personalized meals, or even foods designed for people with specific health needs. Chefs, food companies, and researchers are exploring how this technology can change the way we prepare and enjoy food.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

As more people become interested in healthier, personalized, and sustainable eating habits, the demand for 3D food printing is rising. This technology allows the creation of meals that are tailored to individual needs, such as specific nutrient levels or soft textures for elderly people. It also opens up new options in food presentation, making meals more exciting. Schools, hospitals, and restaurants are among the places testing this technology. With growing interest in smart kitchens and new food experiences, 3D food printing is finding a place in the future of food.

A number of trends are shaping the growth of 3D food printing. One major trend is the focus on reducing food waste. By using leftover food, food powder, or byproducts from farming, 3D printers can turn unused materials into edible products. Another trend is the rise of plant-based diets. Food printers can easily use vegetable-based ingredients to form meat-like structures. There is also interest in using 3D printing to make food more accessible, especially for people who have trouble chewing or swallowing.

Several important events have helped bring attention to 3D food printing. Space agencies like NASA have tested food printers to prepare meals for astronauts. Some large food companies and tech startups have launched pilot programs or small production units to try out the technology in kitchens and cafeterias. There have also been public demonstrations at food festivals, trade shows, and even museums, where people could see printed food and sometimes taste it.

Researchers and universities have played a big role in pushing 3D food printing forward. They are studying how different ingredients behave during the printing process and how taste, texture, and nutrition can be improved. Some projects are exploring how to print food using new proteins from algae, insects, or lab-grown meat. These efforts aim to make the technology more flexible, useful, and appealing to a wider group of people.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Looking ahead, 3D food printing may become more common in homes and restaurants. As the machines become easier to use and cheaper to make, more people might try printing their own meals. The technology could help reduce food waste, offer customized nutrition, and bring creativity to food design. Although it is still developing, 3D food printing is opening the door to new ways of thinking about food and how it fits into our lives.

The US 3D Food Printing Market

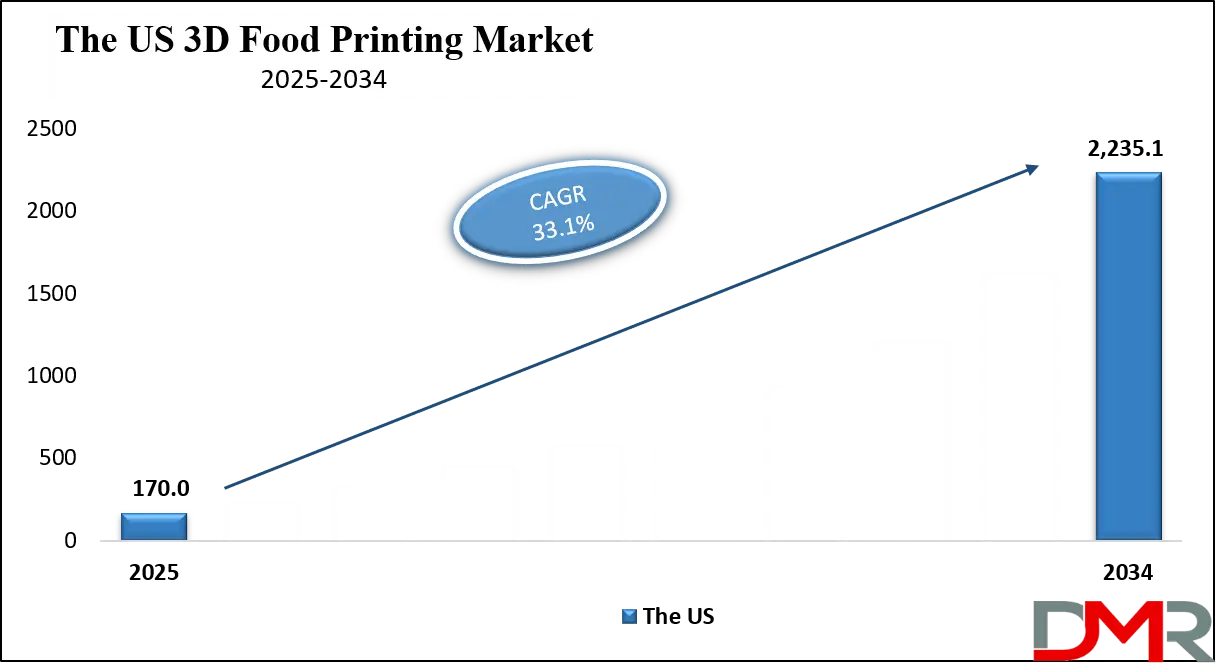

The US 3D Food Printing Market size is projected to reach USD 170.0 million in 2025 at a compound annual growth rate of 33.1% over its forecast period.

The US plays a leading role in the 3D food printing market through strong investment in research and innovation. Many US-based universities and tech companies are developing advanced 3D food printing technologies and new printable ingredients. The country’s focus on personalized nutrition and health drives demand for customized meals created by 3D printers.

Additionally, the US food industry is exploring sustainable food production methods, where 3D printing offers solutions like reducing waste and using alternative proteins. The presence of a large and diverse consumer base also supports market growth, with restaurants, healthcare facilities, and even space agencies testing 3D printed food. Overall, the US is a key player shaping the future of 3D food printing through technology development and early adoption.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Europe 3D Food Printing Market

Europe 3D Food Printing Market size is projected to reach USD 163.2 million in 2025 at a compound annual growth rate of 34.8% over its forecast period.

Europe holds a significant position in the global 3D food printing market, as countries like Germany, the United Kingdom, and the Netherlands are at the forefront of adopting and advancing this technology. The region's strong emphasis on sustainability and innovation in food production drives the demand for 3D-printed food solutions. European consumers exhibit a growing interest in personalized nutrition and sustainable food options, aligning with the capabilities of 3D food printing to create customized and eco-friendly meals.

Moreover, Europe's robust regulatory framework ensures the safety and quality of 3D-printed foods, fostering consumer confidence and encouraging market growth. The integration of 3D food printing into various sectors, including healthcare, hospitality, and retail, further underscores Europe's pivotal role in shaping the future of food technology.

Japan 3D Food Printing Market

Japan 3D Food Printing Market size is projected to reach USD 27.2 million in 2025 at a compound annual growth rate of 38.1% over its forecast period.

Japan plays an important role in the 3D food printing market thanks to its focus on technology and an aging population that needs personalized nutrition. The country is known for being open to new innovations, which helps in adopting this technology in hospitals, elderly care, restaurants, and schools. 3D food printing offers solutions for creating meals that meet specific dietary needs, improving health and quality of life for many people.

Although there are challenges like the high cost of equipment and limited consumer awareness, Japan’s strong interest in technology and healthcare creates good opportunities for growth. This makes Japan a key player in advancing 3D food printing within Asia and the global market.

3D Food Printing Market: Key Takeaways

- Market Growth: The 3D Food Printing Market size is expected to grow by USD 7,777.2 million, at a CAGR of 35.4%, during the forecasted period of 2026 to 2034.

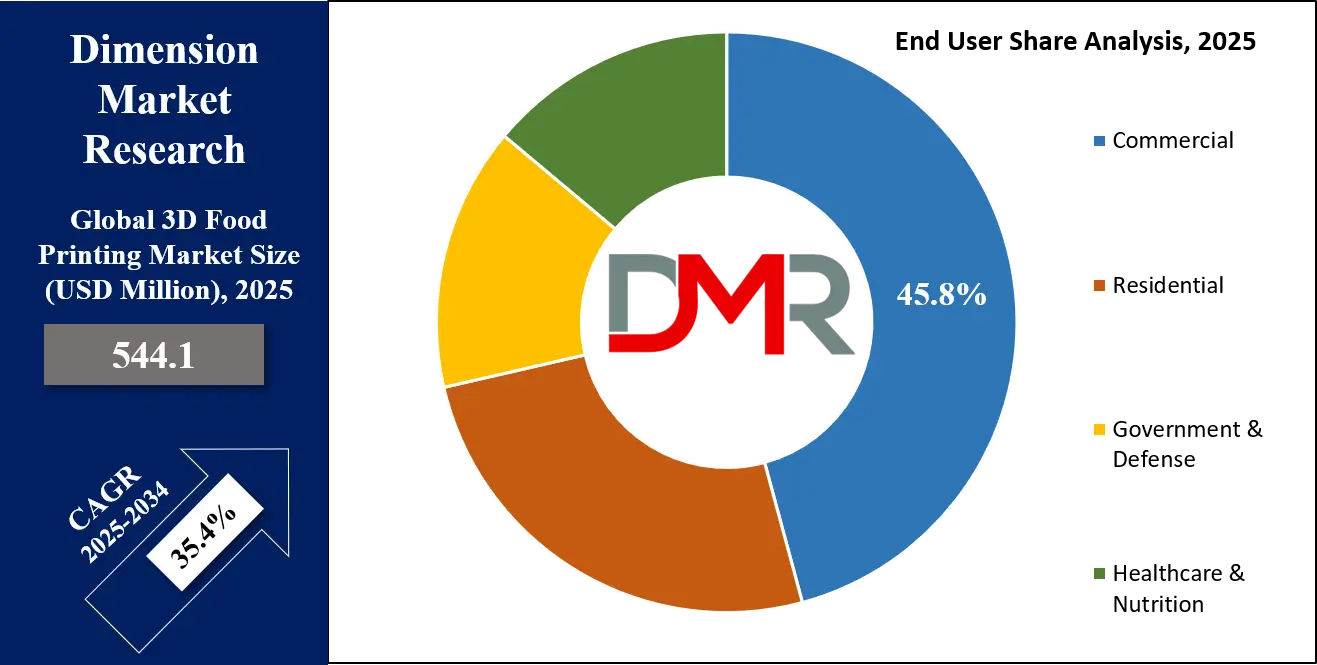

- By End User: The commercial segment is anticipated to get the majority share of the 3D Food Printing Market in 2025.

- By Technology: The Extrusion-Based Printing segment is expected to get the largest revenue share in 2025 in the 3D Food Printing Market.

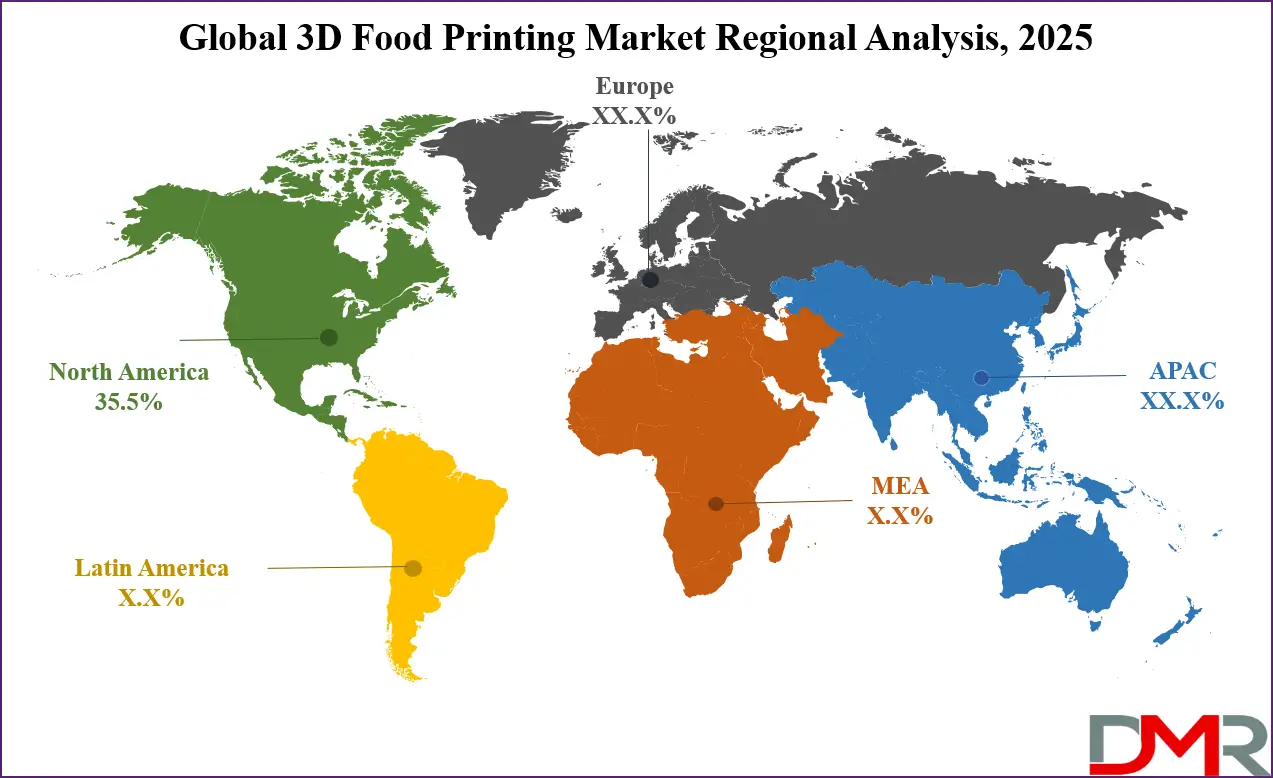

- Regional Insight: North America is expected to hold a 35.5% share of revenue in the Global 3D Food Printing Market in 2025.

- Use Cases: Some of the use cases of 3D Food Printing include personalized nutrition, sustainable food solutions, and more.

3D Food Printing Market: Use Cases

- Personalized Nutrition: 3D food printing can create meals tailored to individual dietary needs, which is helpful for people with specific health conditions, allergies, or nutritional goals. It allows precise control of ingredients, vitamins, and portion sizes for a healthier lifestyle.

- Food for the Elderly and Patients: People with difficulty chewing or swallowing can benefit from 3D-printed meals. Soft, pureed foods can be printed into familiar shapes, making them more appealing and easier to eat. This improves both nutrition and quality of life for patients in hospitals or elderly care.

- Sustainable Food Solutions: 3D printing can use alternative ingredients like insect protein, algae, or food waste. These help reduce environmental impact and make better use of resources. It supports sustainable food production and reduces food loss.

- Creative Culinary Design: Chefs and food artists use 3D printing to create detailed, artistic food designs. It allows for shapes and textures that are hard to achieve by hand. This adds creativity and uniqueness to dishes served in high-end restaurants or events.

Market Dynamic

Driving Factors in the 3D Food Printing Market

Rising Demand for Personalized and Functional Foods

One of the key drivers of growth in the 3D food printing market is the increasing interest in personalized and functional nutrition. Consumers are becoming more health-conscious and are looking for food options that fit their specific dietary needs, such as low sugar, high protein, gluten-free, or enriched with certain vitamins. 3D food printing makes it possible to prepare meals that are customized for individuals, whether for fitness goals, medical conditions, or age-related dietary requirements.

This level of customization is difficult to achieve with traditional food manufacturing. As more people seek out tailored nutrition, from athletes to elderly patients, the ability of 3D printing to deliver made-to-order meals is becoming more attractive. This is encouraging investment and innovation in the market.

Technological Advancements and Innovation in Food Materials

Another important growth driver is the rapid improvement in 3D printing technology and the development of new printable food materials. Over time, printers have become faster, more accurate, and easier to use, making them more practical for both commercial and home use. At the same time, researchers and food companies are expanding the range of ingredients that can be printed—from chocolate and dough to vegetable pastes and alternative proteins.

These innovations allow more complex textures, flavors, and food combinations to be created. As the technology matures, it becomes possible to use 3D printers not just for decoration, but for full meal preparation. This continuous progress in hardware and food science is expanding the potential uses of 3D food printing across different industries and regions.

Restraints in the 3D Food Printing Market

High Cost of Equipment and Ingredients

One major restraint in the growth of the 3D food printing market is the high cost of the printers and specialized food materials needed. Advanced 3D food printers can be expensive to buy and maintain, which limits their accessibility for small businesses, restaurants, and individual consumers.

Additionally, the food pastes or powders designed for printing are often more costly than regular ingredients due to the processing required to make them printable. This makes the overall process less affordable, especially in regions where budget-friendly food options are essential. Until prices come down, the technology may remain a niche product rather than becoming mainstream. Cost challenges slow wider adoption and investment in this emerging market.

Limited Consumer Awareness and Acceptance

Another significant challenge is the low level of consumer awareness and acceptance of 3D printed food. Many people are unfamiliar with the concept and may feel hesitant about eating food created by machines rather than traditional cooking methods. Concerns about taste, texture, and safety also affect willingness to try 3D printed meals. Cultural preferences and habits around food preparation can make it difficult to introduce this new technology broadly. Without clear education and demonstrations of benefits, consumers may be slow to embrace 3D food printing. This limits demand growth and reduces the incentive for businesses to invest heavily in the technology.

Opportunities in the 3D Food Printing Market

Expansion in Healthcare and Specialized Diets

The healthcare sector presents a significant opportunity for the 3D food printing market to grow. Customized nutrition is crucial for patients with specific medical conditions, such as diabetes, allergies, or swallowing difficulties. 3D food printing can produce meals tailored exactly to these needs, improving patient care and recovery. Hospitals, nursing homes, and rehabilitation centers could adopt this technology to offer better meal solutions that are both nutritious and appealing.

Additionally, as the global population ages, there will be increased demand for soft and easy-to-eat foods. This opens a large market for 3D printed foods designed specifically for the elderly and people with special dietary requirements, creating new revenue streams for the industry.

Innovations in Sustainable and Alternative Food Sources

There is a major global focus on sustainability and reducing the environmental impact of food production, which creates strong opportunities for 3D food printing. The technology can utilize alternative protein sources such as plant-based ingredients, insect protein, or lab-grown materials to produce nutritious and eco-friendly meals. By converting food waste and byproducts into edible materials, 3D printing can also help reduce overall food loss. This aligns well with consumer trends toward environmentally conscious eating. As governments and organizations push for more sustainable food systems, 3D food printing stands to benefit from increased support and funding, enabling it to play a key role in the future of sustainable food innovation.

Trends in the 3D Food Printing Market

Integration of AI and Machine Learning in Food Design

A significant trend in the 3D food printing market is the incorporation of artificial intelligence (AI) and machine learning to enhance food design and production processes. These technologies enable the optimization of recipes based on nutritional requirements and consumer preferences. AI systems analyze large datasets to suggest ingredient substitutions, improve food texture and flavor, and ensure consistency in printed products. This integration not only streamlines the production process but also allows for the creation of personalized meals tailored to individual dietary needs, thereby expanding the potential applications of 3D food printing in various sectors, including healthcare and personalized nutrition.

Diversification of Ingredients and Sustainability Focus

The 3D food printing industry is diversifying its use of ingredients, moving beyond traditional materials like chocolate and sugar to incorporate plant-based proteins, fruits, vegetables, and even cell-cultured meat. This expansion opens up new opportunities for creating customized nutrition products tailored to specific dietary needs, such as vegan, gluten-free, and high-protein diets.

Additionally, there is a strong focus on sustainability within the industry. By enabling on-demand production and precise portioning, 3D food printing significantly reduces food waste, addressing one of the major environmental concerns in the food sector. Furthermore, the development of sustainable materials, such as biodegradable packaging or eco-friendly ingredients, demonstrates the industry’s commitment to minimizing its environmental impact.

Research Scope and Analysis

By Ingredient Analysis

Dough as an ingredient will play a key role in the growth of the 3D food printing market in 2025, with an estimated share of around 27.9%. Dough’s versatility and ease of use make it ideal for printing a wide variety of foods like bread, pizza, and pastries. Its texture allows for precise layering and shaping, which suits the 3D printing process well. The popularity of bakery and snack products made from dough also drives demand for this ingredient in food printers.

As consumers look for personalized and freshly made baked goods, dough-based 3D printing offers new possibilities for creativity and convenience. This helps expand the market, especially in restaurants and home kitchens where quick, customized baked items are desired. Dough’s compatibility with the technology makes it a significant factor in advancing 3D food printing during this period.

Proteins as an ingredient are expected to see significant growth in the 3D food printing market over the forecast period, driven by rising interest in personalized nutrition and alternative protein sources. Protein-rich materials like plant-based powders, insect proteins, and cultured meat are increasingly used to create nutritious, sustainable food products through 3D printing. The rise of autonomous service robots that can prepare and deliver 3D printed meals in settings like hotels and hospitals is also supporting this growth. These robots help combine 3D printed protein foods with efficient service, meeting the demand for healthy, customized meals. Together, protein ingredients and smart automation are helping shape the future of 3D food printing technology.

By Technology Analysis

Extrusion-based printing technology will hold a leading position in the 3D food printing market in 2025, with an estimated share of about 45.1%. This technology works by pushing food materials like dough, chocolate, or purees through a nozzle to build up layers and create precise shapes. Its ability to handle a wide range of food textures and ingredients makes it very popular for both commercial and home use. Extrusion printing offers high accuracy and customization, which supports the growing demand for personalized meals and creative food designs. The ease of use and relatively lower cost compared to other methods also contribute to its strong adoption. Because of these advantages, extrusion-based printing is set to be a major driver in advancing 3D food printing technology during this time.

Selective sintering technology is expected to grow significantly in the 3D food printing market over the forecast period, supported by the increasing use of autonomous service robots. This technology uses heat to fuse powdered food materials layer by layer, allowing the creation of complex and detailed food items. Selective sintering enables faster production and can work with a variety of ingredients, which is helpful in places like restaurants and hospitals.

Autonomous robots equipped with this technology can prepare and deliver customized meals efficiently, improving service quality and speed. The combination of selective sintering and automation is helping to expand the applications of 3D food printing in both commercial and healthcare sectors.

By Application Analysis

Bakery products are expected to play a significant role in the growth of the 3D food printing market in 2025, holding an estimated share of around 31.5%. This application benefits from the ability to create intricate designs and personalized baked goods, such as cakes, pastries, and bread, which are difficult to produce by traditional methods. 3D printing allows bakeries and home users to customize shapes, flavors, and nutritional content easily.

The demand for visually appealing and unique bakery items drives interest in this technology. Additionally, the efficiency and precision of 3D food printing help reduce waste and speed up production. These factors together position bakery products as a key segment contributing to the expansion of 3D food printing technology during this period.

Meat and seafood applications are expected to see significant growth in the 3D food printing market over the forecast period, supported by advances in autonomous service robots. These robots can efficiently prepare and deliver 3D printed protein-rich meals in restaurants, hotels, and healthcare settings. Using 3D printing, customized meat and seafood products with specific textures and flavors can be created, including plant-based or cultured alternatives. This helps meet growing consumer demand for sustainable and personalized protein options. The combination of 3D printing technology with smart robotics enhances production speed, reduces human labor, and ensures consistent quality, making meat and seafood applications an important area of market growth.

By End User Analysis

Commercial end users are expected to lead the growth of the 3D food printing market in 2025, with an estimated share of around 45.8%. This segment includes restaurants, catering services, and food service providers who use 3D printing to create customized and visually appealing food items quickly and efficiently. The technology helps commercial users reduce food waste and improve menu variety by producing unique shapes, flavors, and textures that are difficult to achieve with traditional methods.

As consumer demand for personalized and innovative dining experiences increases, more commercial businesses are adopting 3D food printing. This trend is boosting the market by offering new ways to attract customers and improve operational efficiency, making commercial end users a major driver of 3D food printing adoption during this period.

Health and nutrition end users are set to experience significant growth in the 3D food printing market over the forecast period, supported by the integration of autonomous service robots. These robots help prepare and deliver personalized meals in hospitals, care centers, and wellness facilities, ensuring precise nutrition tailored to individual health needs.

3D food printing allows for customization of ingredients, textures, and portion sizes, which benefits patients with dietary restrictions or special nutritional requirements. The use of service robots enhances efficiency and hygiene in meal preparation and delivery. Together, health and nutrition applications with advanced automation are driving innovation and expanding the role of 3D food printing in improving patient care and personalized wellness.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

The 3D Food Printing Market Report is segmented on the basis of the following:

By Ingredient

- Dough

- Fruits and Vegetables

- Dairy Products

- Proteins

- Carbohydrates

- Sauces

- Others

By Technology

- Fused Deposition Modeling (FDM)

- Inkjet Printing

- Selective Sintering

- Binder Jetting

- Extrusion-Based Printing

- Others

By Application

- Bakery Products

- Confectionery

- Meat & Seafood

- Pasta and Noodles

- Nutrition

- Others

By End User

- Commercial

- Residential

- Government & Defense

- Healthcare & Nutrition Institutions

Regional Analysis

Leading Region in the 3D Food Printing Market

North America is set to lead the growth of the 3D food printing market in 2025, holding an estimated share of around 35.5%. This region’s strong position comes from early adoption of advanced food technologies and a focus on personalized nutrition and innovative food experiences. Many companies and research institutions in North America are investing in developing new 3D food printers and printable ingredients. The growing interest in healthier eating, sustainability, and reducing food waste also supports the market’s expansion.

Additionally, sectors like healthcare and hospitality are exploring 3D food printing to offer customized meals, especially for people with special dietary needs. Consumer openness to technology and continuous innovation help North America maintain its leadership. As demand increases for convenient, nutritious, and creative food solutions, the region remains a key driver in shaping the future of 3D food printing on a global scale.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Fastest Growing Region in the 3D Food Printing Market

Asia Pacific is showing significant growth in the 3D food printing market over the forecast period, driven by rising technological advancements and increasing consumer interest in innovative food solutions. Countries in this region are investing in research and development to improve 3D printing technology for food applications. Growing awareness of personalized nutrition and the need for sustainable food production are also encouraging adoption.

The expanding food service industry and healthcare sector in Asia Pacific contribute to the rising demand for customized and convenient meals made through 3D food printing. With more startups and established companies entering the market, the region is becoming an important player in advancing this technology during 2025 and beyond.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The 3D food printing market is growing with many different players entering from various industries, such as food technology, kitchen appliances, and research. Some focus on building the actual printers, while others develop special food materials or software to control the printing process. There are also companies working on offering 3D printed food as a service, like in restaurants or for events.

Startups are bringing fresh ideas, while bigger companies bring more resources and global reach. Research institutions and universities are also involved, helping improve the technology. With increasing interest in personalized nutrition, sustainability, and food innovation, the competition is becoming stronger. Each group is trying to stand out by offering better design, speed, ease of use, and new food possibilities.

Some of the prominent players in the global 3D Food Printing are:

- 3D Systems Corp

- TNO

- Natural Machines

- ByFlow

- Redefine Meat

- SavorEat

- Bocusini

- Opean Meals

- Colido

- Nufood

- Jet Eat

- Digital Patisserie

- Gastronology

- Delicious Innovations

- Magic Candy Factory

- FoodJet

- Cui Kitchen

- Modern Meadow

- Other Key Players

Recent Developments

- In April 2025, Revo Foods launched “El Blanco,” a black cod analog made from fungi protein and microalgae oils. The product is created using 3D extrusion technology, giving it the realistic look and texture of fish fillets. Revo uses computer-guided 3D printing to shape unstructured mycoproteins into flaky fish-like forms. Backed by three patents, the company opened the world’s largest industrial 3D food extrusion facility in 2024 to scale and commercialize its protein analog innovations.

- In April 2025, Velo3D, Inc. announced that Mears Machine Corporation of Indianapolis has acquired its fourth Sapphire XC printer to expand its AM capabilities amid rising customer demand. Known for precision machining, Mears Machine had already added three Sapphire XCs in 2024, which highlights the company’s ongoing commitment to adopting cutting-edge manufacturing technology and strengthening its position in aerospace and defense supply chains through advanced additive manufacturing solutions.

- In January 2025, 3DPRINTUK has announced a GBP 2 million investment to expand its additive manufacturing capacity in London, becoming the UK’s largest provider of HP’s Multi Jet Fusion technology. As part of the TriMech Group, the company will add three HP 5210 PRO systems, increasing its total to eight machines.

- In September 2024, Steakholder Foods Ltd, a pioneer in alternative proteins and 3D printing, has opened its first full-scale Demonstration Center, which highlights the company’s cutting-edge 3D printers, the MX200 and HD144, with live demonstrations of real-time production of plant-based meat and seafood alternatives. The center is designed to showcase the technology’s capabilities and enhance customer interaction, offering a hands-on experience with Steakholder’s innovative approach to sustainable food production.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 544.1 Mn |

| Forecast Value (2034) |

USD 8,321.3 Mn |

| CAGR (2025–2034) |

35.4% |

| The US Market Size (2025) |

USD 170.0 Mn |

| Historical Data |

2019 – 2024 |

| Forecast Data |

2026 – 2034 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors, etc. |

| Segments Covered |

By Ingredient (Dough, Fruits and Vegetables, Dairy Products, Proteins, Carbohydrates, Sauces, and Others), By Technology (Fused Deposition Modeling (FDM), Inkjet Printing, Selective Sintering, Binder Jetting, Extrusion-Based Printing, and Others), By Application (Bakery Products, Confectionery, Meat & Seafood, Pasta and Noodles, Nutrition, and Others), By End User (Commercial, Residential, Government & Defense, and Healthcare & Nutrition Institutions)

|

| Regional Coverage |

North America – US, Canada; Europe – Germany, UK, France, Russia, Spain, Italy, Benelux, Nordic, Rest of Europe; Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, Rest of MEA |

| Prominent Players |

3D Systems Corp, TNO, Natural Machines, ByFlow, Redefine Meat, SavorEat, Bocusini, Opean Meals, Colido, Nufood, Jet Eat, Digital Patisserie, Gastronology, Delicious Innovations, Magic Candy Factory, FoodJet, Cui Kitchen, Modern Meadow, and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days, and 5 analysts working days respectively. |

Frequently Asked Questions

How big is the Global 3D Food Printing Market?

▾ The Global 3D Food Printing Market size is expected to reach a value of USD 544.1 million in 2025 and is expected to reach USD 8,321.3 million by the end of 2034.

Which region accounted for the largest Global 3D Food Printing Market?

▾ North America is expected to have the largest market share in the Global 3D Food Printing Market, with a share of about 35.5% in 2025.

How big is the 3D Food Printing Market in the US?

▾ The 3D Food Printing Market in the US is expected to reach USD 170.0 million in 2025

Who are the key players in the Global 3D Food Printing Market?

▾ Some of the major key players in the Global 3D Food Printing Market are 3D Systems Corp, TNO, Natural Machines, and others

What is the growth rate in the Global 3D Food Printing Market?

▾ The market is growing at a CAGR of 35.4 percent over the forecasted period.