Market Overview

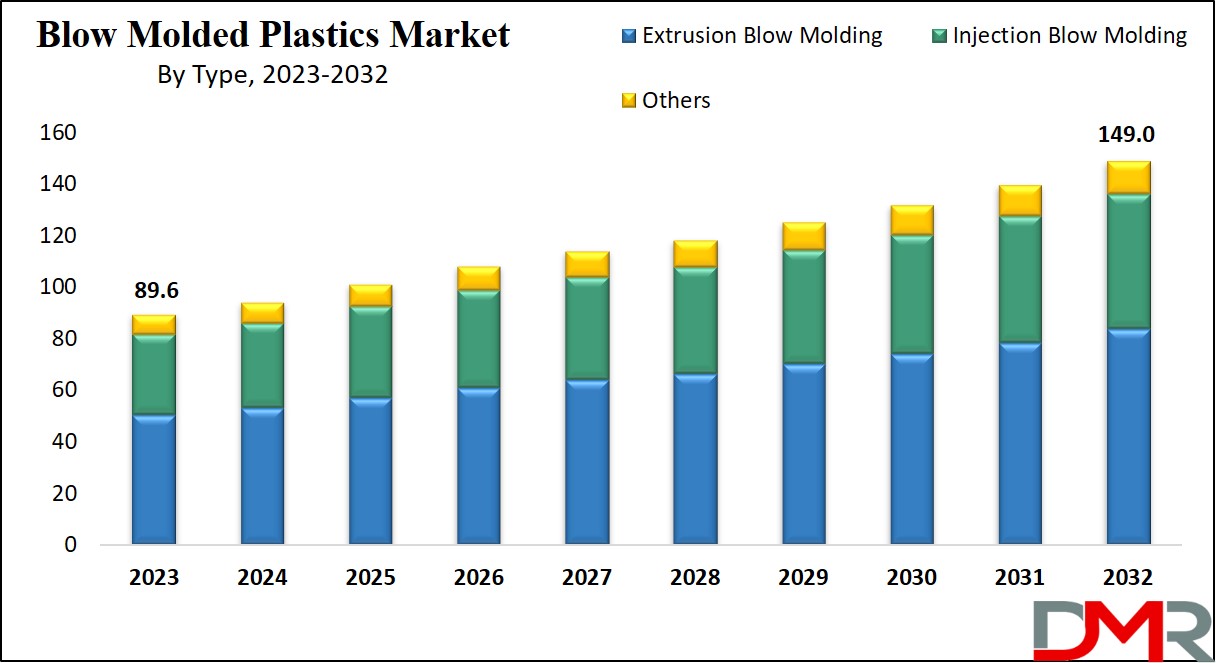

The Global Blow Molded Plastics Market is expected to reach a valuation of USD 89.6 billion in 2023 and USD 149 billion in 2032. It is anticipated to grow with a CAGR of 5.6% for the forecast period (2023-2032).

Blow molding is a method used to craft hollow plastic items from thermoplastic materials. Plastics formed by blow molding procedures start by heating & inflating a plastic tube, also known as a preform. This Preform is positioned between two molds shaped according to the desired product. Air is introduced to inflate the tube, causing its walls to become thinner and match the mold's shape.

After the blowing stage, the product undergoes cooling, ejection, trimming, and preparation for subsequent processes. Basic steps in Blow molding follow a simple sequence involving melting, blending, extrusion, blowing, cooling, & ejection. Various production facilities might incorporate extra steps like additional cooling or heating rounds, as well as mixing in additives and colorants. These added stages rely on the specific design & planned use of the end product.

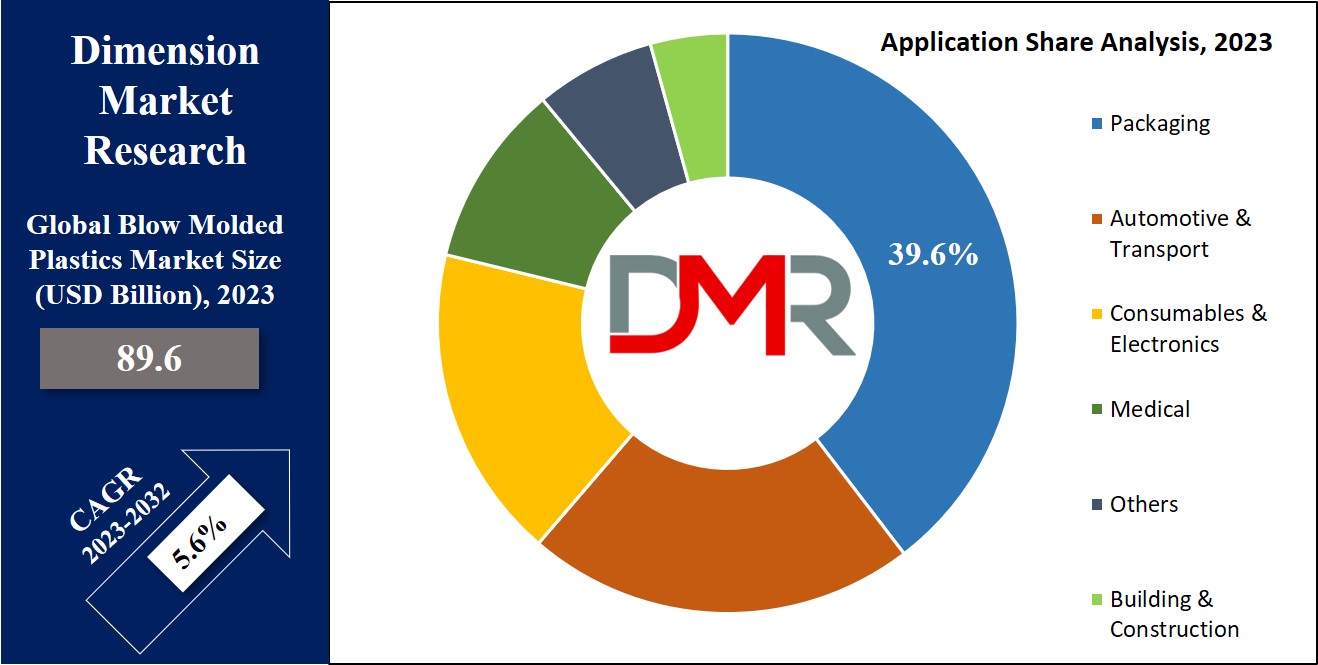

The market is segmented on the basis of Type (Injection Blow Molding, Extrusion Blow Molding, and Others), By Resins PE, PP, PA, PC, PET, PVC, and Others), and By Application (Packaging, Automotive & Transport, Consumables & Electronics, Building & Construction, Medical, and Others).

Key Takeaways

- Market Growth: The blow molded plastics market is projected to grow from USD 89.6 billion in 2023 to USD 149 billion by 2032, at a 5.6% CAGR over the forecast period.

- Key Application: Packaging leads as the main application, accounting for over 39% of market revenue, with automotive and transport as another significant segment.

- Dominant Type: Extrusion blow molding holds the largest market share due to lightweight and durable products, supporting cost and environmental benefits.

- Resin Leader: Polyethylene is the top resin used, dominating the market due to widespread application in packaging, electronics, and everyday household items.

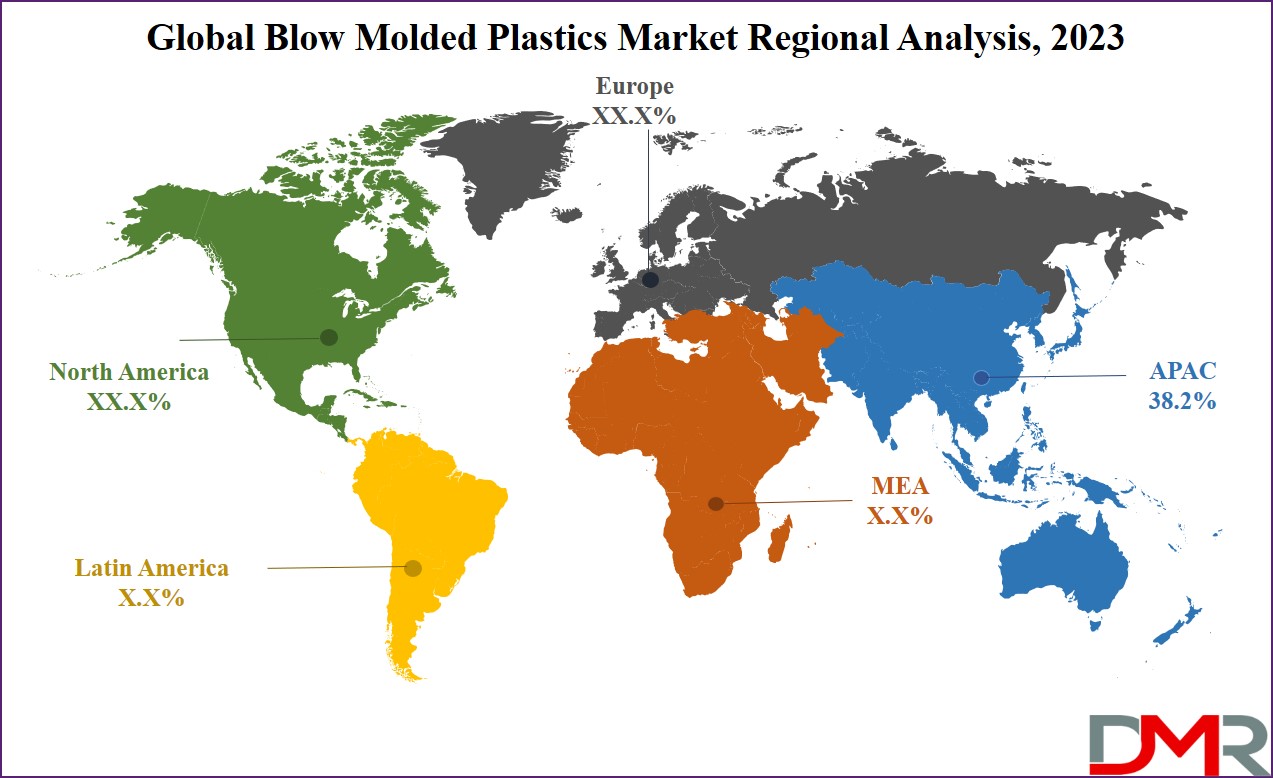

- Regional Dominance: Asia-Pacific region commands the market with a 38.2% share in 2023, driven by rapid urbanization, construction, and rising consumer spending.

- Sustainability Focus: Market faces pressure to adopt eco-friendly practices, with emphasis on recycled materials and circular economy to address environmental concerns.

- Competitive Strategy: Key companies focus on product innovation, strategic partnerships, and recyclable plastics to stay competitive and adapt to regulatory trends.

Use Cases

- Consumer Packaging: Utilized for producing lightweight, durable bottles and containers for food, beverages, toiletries, and household products, ensuring extended shelf life and cost-effective transport.

- Automotive Components: Applied in manufacturing fuel tanks, ducts, and other automotive parts, offering weight reduction and improved fuel efficiency for vehicles.

- Medical Supplies: Used for creating safe, sterile containers and bottles for storing pharmaceuticals, laboratory reagents, and healthcare fluids, supporting stringent medical and safety standards.

- Industrial Containers: Employed to make large-capacity drums, tanks, and bins for packaging chemicals, oils, and industrial fluids, enhancing workplace safety and material handling efficiency.

- Personal Care Packaging: Enables production of ergonomic and visually appealing bottles for shampoos, lotions, and cosmetics, catering to evolving consumer preferences and branding needs.

- Building Materials: Supports manufacturing of construction items like water tanks, pipes, and ducts, providing durability and affordability for infrastructure and real estate projects.

Market Dynamic

The demand for blow-molded plastics is primarily fueled by the packaging sector. Plastic containers, jars, and bottles, created through blow molding find extensive use in packaging food, beverages, personal care items, & household chemicals. The rising customer goods industry, evolving lifestyles, & the growing preference for convenient packaging have greatly elevated the desire for blow-molded plastics.

Blow-molded plastics play a vital role in the automotive sector, being widely used for crafting air ducts, fuel tanks, dashboards, bumpers, & interior trims. The automotive sector’s ongoing focus on lightweight items, aiming to enhance fuel efficiency & lower emissions, has resulted in a growing embrace of blow-molded plastics.

Despite their advantages, these plastics have raised concerns regarding their environmental impact, especially concerning plastic waste & pollution. Heightened awareness about plastic pollution & the rising demand for eco-friendly options have resulted in regulatory actions & consumer choices shifting toward more sustainable choices. Consequently, sectors are under pressure to get new alternative materials & reduce their dependence on conventional blow-molded plastics.

Research Scope and Analysis

By Type

Extrusion blow molding has captured a huge share of this market in 2023. This method creates

plastic products that are both durable & lightweight, making them ideal for sectors such as packaging. The property of lightweight in these products reduces the costs of transportation and impact on the environment. Albeit they are light, they maintain good structural integrity, enduring handling & challenges related to transportation. Moreover, extrusion blow molding supports environmental sustainability by enabling the use of recycled plastic items, lessening reliance on new resins, & promoting a circular economy. Furthermore, the products' lightweight design helps in lowering carbon emissions during transportation.

By Resin

Under the Resin segment, the

Polyethylene category leads the market with a maximum share as compared to other categories. This dominance can be attributed to its widespread utilization in the electrical & electronics & packaging sectors. They are commonly employed in several packaging applications producing bottles for a diverse range of products including chemicals & food items due to their lightweight properties which further reduce the cost of logistics. It is also used in manufacturing various household products such as containers, drums, & toys, etc.

Polyethylene terephthalate also sees extensive use in the packaging sector, particularly in producing bottles for beverages & food items. Amid the recent pandemic, PE & PET demand is anticipated to surge due to the increased need for protective gowns, face masks, & bottles utilized for hand sanitizers.

By Application

Under the application segment, the packaging sub-segment leads the global blow-molded plastics market, accounting for more than 39% of the total revenue in the blow-molded plastics market. This sector's growth is mainly propelled by high consumer spending in developing countries. The packaging sector's expansion is expected to drive the need for plastic materials like polyethylene and polyethylene terephthalate during the forecast period. The blow-molded plastics requirements are notably rising in the packaging sector, driven by the increased need for plastic bottles utilized for disinfectants, hand sanitizers, household cleaning solutions, & several other products amid the recent pandemic.

Another segment having a good chunk of share is Automotive & Transport after the packaging sector. The growing use of plastics in car parts, along with the simultaneous increase in the manufacturing of e-cars & large vehicles, especially in South & Central America and Asia is set to drive the growth of this sector in the predicted period.

The Global Blow Molded Plastics Market Report is segmented on the basis of the following:

By Type

- Injection Blow Molding

- Extrusion Blow Molding

- Others

By Resins

- Polyethylene (PE)

- Polypropylene (PP)

- Polyamide (PA)

- Polycarbonate (PC)

- Polyethylene terephthalate (PET)

- Polyvinyl Chloride (PVC)

- Others

By Application

- Packaging

- Automotive & Transport

- Consumables & Electronics

- Building & Construction

- Medical

- Others

Regional Analysis

Asia-Pacific region dominates the Global Blow Molded Plastics Market, securing a maximum

share of 38.2% in global revenue in 2023. In Asia-Pacific, cities are growing fast, which means more buildings & roads are being made. Plastic items made through blow molding, like tanks, pipes, & insulation materials, are extensively utilized in construction. The demand for these plastics has gone up because people need more affordable homes, buildings, as well as factories.

Moreover, in Asia-Pacific, there are many people who buy things. The middle class is getting bigger, & people have more money to spend on products like electronics, packaged goods, & car parts. Blow-molded plastics are popular in these areas as they are versatile, affordable, & can meet the needs of a growing market.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

In the global market for blow-molded plastics, several key players compete to provide plastic products for different sectors. These players, big & small, use strategies like creating new products, joining forces with others, and making their existing products better to stay ahead. Changes in technology, what people want, and environmental concerns affect how the market works. With industries like automotive, packaging, & everyday items needing lightweight and environmentally friendly plastic, companies keep working on new ideas and ways to be eco-friendly. They also pay attention to rules about the environment and focus on making plastics that can be recycled, showing how the sector is moving toward greener & better alternative options.

Some of the prominent players in the Global Blow Molded Plastics Market are:

- Dow Inc.

- Comar, LLC

- Magna International, Inc.

- Gemini Group, Inc.

- Custom -Pak

- Creative Blow Mold Tooling

- Garrtech, Inc.

- Rutland Plastics Ltd.

- The Plastic Forming Company, Inc.

- Agri-Industrial Plastics

- APEX Plastics

- Other Key Players

Recent Developments

- In January 2025, Amcor and Berry Global announced a $10.5 billion merger, reshaping the plastics industry and expanding their packaging capabilities globally.

- In July 2025, industry reports confirmed seven significant blow molding M&A deals completed so far in 2025, exceeding the previous year's activity levels.

- In May 2025, PLASTPOL 2025 in Poland showcased new blow molding product innovations, with several companies launching advanced processing machines and recycling lines.

- In August 2025, the SPE Blow Molding Division recognized notable product launches and technology demonstrations by leading industry players at the sold-out ABC 2025 tradeshow.

- In June 2025, the 10th Injection, Blow Moulding & PET International Summit in Mumbai featured 60+ booths highlighting new products and solutions across the blow molding value chain.

Report Details

| Report Characteristics |

| Market Size (2023) |

USD 89.6 Bn |

| Forecast Value (2032) |

USD 149 Bn |

| CAGR (2023–2032) |

5.6% |

| Historical Data |

2017 – 2022 |

| Forecast Data |

2023 – 2032 |

| Base Year |

2022 |

| Estimate Year |

2023 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Type (Injection Blow Molding, Extrusion Blow Molding, and Others), By Resins (PE, PP, PA, PC, PET, PVC, and Others), and By Application (Packaging, Automotive & Transport, Consumables & Electronics, Building & Construction, Medical, and Others). |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA. |

| Prominent Players |

Dow Inc., Comar, LLC, Magna International, Inc., Gemini Group, Inc., Custom-Pak, Creative Blow Mold Tooling, Garrtech, Inc., Rutland Plastics Ltd., The Plastic Forming Company, Inc., Agri-Industrial Plastics, APEX Plastics, and Other Key Players. |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |

Frequently Asked Questions

The Global Blow Molded Plastics Market is expected to reach a valuation of USD 89.6 billion in 2023 and

USD 149 billion in 2032.

The expected CAGR for the Global Blow Molded Plastics Market is 5.6% for the forecast period (2023-

2032).

Asia-Pacific region dominates the Global Blow Molded Plastics Market with a maximum share of 38.2%

in 2023.

Some of the prominent players in the Global Blow Molded Plastics Market include Dow Inc., Comar, LLC,

Magna International, Inc., Gemini Group, Inc., Custom-Pak, Creative Blow Mold Tooling, Garrtech, Inc.,

Rutland Plastics Ltd., The Plastic Forming Company, Inc., Agri-Industrial Plastics, etc.