Market Overview

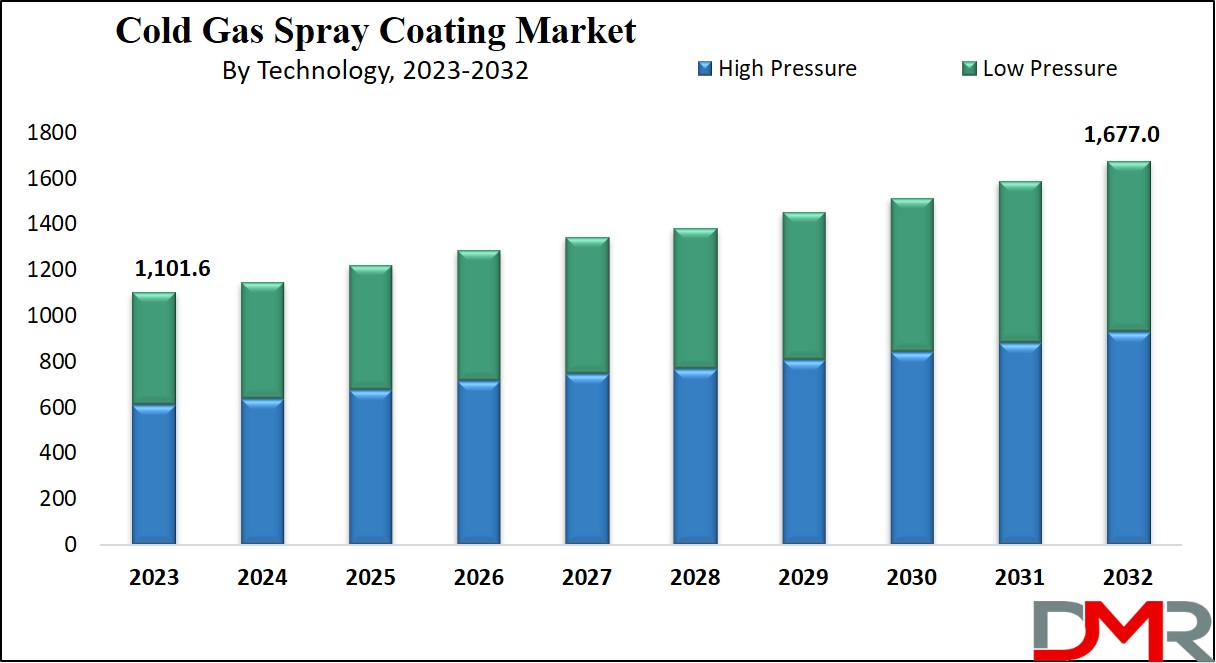

The Global Cold Gas Spray Coating Market is expected to reach a valuation of USD 1,101.6 Million in 2023, and it is anticipated to experience a CAGR of 4.8% for the forecast period (2023-2032).

Cold gas spray coating, also known as CGS coating, is a thermal spray technique that involves propelling powder particles at high speeds using supersonic compressed gas, below their melting point temperatures. This process provides various benefits, such as better coating bond strength & high efficiency of deposition.

It is especially used for maintaining corrosive & structural parts that cannot be effectively maintained through the welding process. The CGS procedure is capable of depositing several materials like metals, composites, ceramics & polymers. When compared to other kinds of thermal sprays, cold gas spray coating stands out because of its capability to enhance hardness, improve adhesion strength, decrease porosity, & preserve the characteristics of source material particulates. These factors propel the growth of the market.

Key Takeaways

- Market Growth: The global cold gas spray coating market is projected to grow from USD 1,101.6 million in 2023 to USD 1,677 million by 2032, at a 4.8% CAGR.

- Technology Advantage: High-pressure cold gas spray technology leads the market due to its ability to deliver dense coatings, superior adhesion, and less substrate damage across automotive, aerospace, and electronics sectors.

- Sector Dominance: The transportation segment, especially automotive and aerospace, dominates cold gas spray coating usage for repair, corrosion protection, and performance improvement of key vehicle components.

- Regional Leadership: North America leads the market thanks to supportive policies for lightweight automotive parts, while Europe is growing due to aerospace and defense investments in advanced coating technologies.

- Material Versatility: Cold gas spray coatings are increasingly used for metals, ceramics, composites, and polymers, meeting needs in medical, oil & gas, electronics, utility, and more, due to strong adhesion and low porosity.

- Key Restraints: Market growth faces challenges from fluctuating raw material costs, supply chain disruptions, and added tariff pressures arising from trade tensions, especially between China and the U.S..

- Competitive Landscape: The market is consolidated with a few global players focusing on R&D to enhance coating functionalities, driven heavily by the needs of the aerospace and automotive sectors for better component longevity.

Use Cases

- Aerospace Repairs: Cold gas spray coatings restore and protect jet engine parts, exhaust systems, pumps, and landing gears in aircraft, enhancing lifespan and reducing costly replacements.

- Automotive Components: Use for protecting pistons, cylinders, brake parts, and manifolds against wear and corrosion, thus improving vehicle reliability and performance in harsh environments.

- Oil & Gas Equipment: Gate valves and drilling components in the oil and gas sector are coated to prevent corrosion and abrasion, minimizing maintenance downtime and extending equipment life.

- Medical Implants: Dental implants and orthopedic prostheses receive biocompatible coatings, helping improve integration, surface durability, and patient outcomes.

- Electronics Manufacturing: Electric motors, circuit boards, connectors, and heat sinks are coated to enhance conductivity, prevent oxidation, and ensure durability in demanding usage conditions.

- Energy Sector Turbines: Solar, nuclear, and hydro steam turbine parts are coated for better performance, higher resistance to extreme conditions, and longer operational lifespans.

Market Dynamic

One of the major driving forces is the growing acceptance of cold gas spray coating in automotive & aerospace aftermarket repair & maintenance purposes. These coatings have changed the component repair systems across sectors, particularly in aerospace, where they have reduced maintenance expenses. Additionally, the rising utilization of amorphous & nanostructured substances in developed electrical device manufacturing has opened up new avenues for more opportunities for key players.

The medical sector is also accepting cold gas spray coating for various uses, further leading to market expansion. Moreover, the customer electronics sector is witnessing significant growth because of the increasing disposable incomes, leading to more demand for cold gas spray-coated components in this sector. With several sectors observing the advantages of cold gas spray coating, the market is poised for continued growth for the forecast period.

However, the market may face several challenges because of the impact of the cost of raw materials. The high costs linked with the extraction process of ore & strict government policies for the mining & metals sectors impact the costs of raw materials utilized in manufacturing cold gas spray coatings. Additionally, the ongoing trade war between the China & United States has resulted in more tariffs, which could further bring volatility to the prices of raw materials in the coming years. These factors work as restraints for the cold gas spray coating market's growth during the forecast period. Despite these challenges, the rising desire & need for cold gas spray coatings in several sectors are expected to propel market growth for the forecast period.

Research Scope and Analysis

By Technology

A segment of High-pressure technology dominates the cold gas spray coating market, with a maximum share in 2023. This technology is extensively utilized for the repairing of surfaces & coating techniques in several sectors, such as automotive, aerospace, & electronics. It is mainly used for repairing metallic components, enhancing the performance of equipment, & enhancing their working life in these sectors. applying pressure up to 50 bars, using axial injection to propel heated raw material particles at a temperature above 1099°C leading to more metal deposition with less oxide & porosity levels while the build-up of material. The procedure provides numerous benefits when compared to other coating processes. It works at lower temperatures, decreasing the chances of the risk of substrate damage. The resulting coatings are dense & have better mechanical characteristics because of the speedier effect of powder particles, leading to enhanced adhesion between the substrate & coating.

Moreover, low-pressure cold gas spraying is another coating technique used for repairing & maintaining light & flexible metal parts across diverse sectors. This method utilizes the surrounding atmosphere as the driving force and works at lower pressure & temperature conditions, making it an economical surface repair & coating technique.

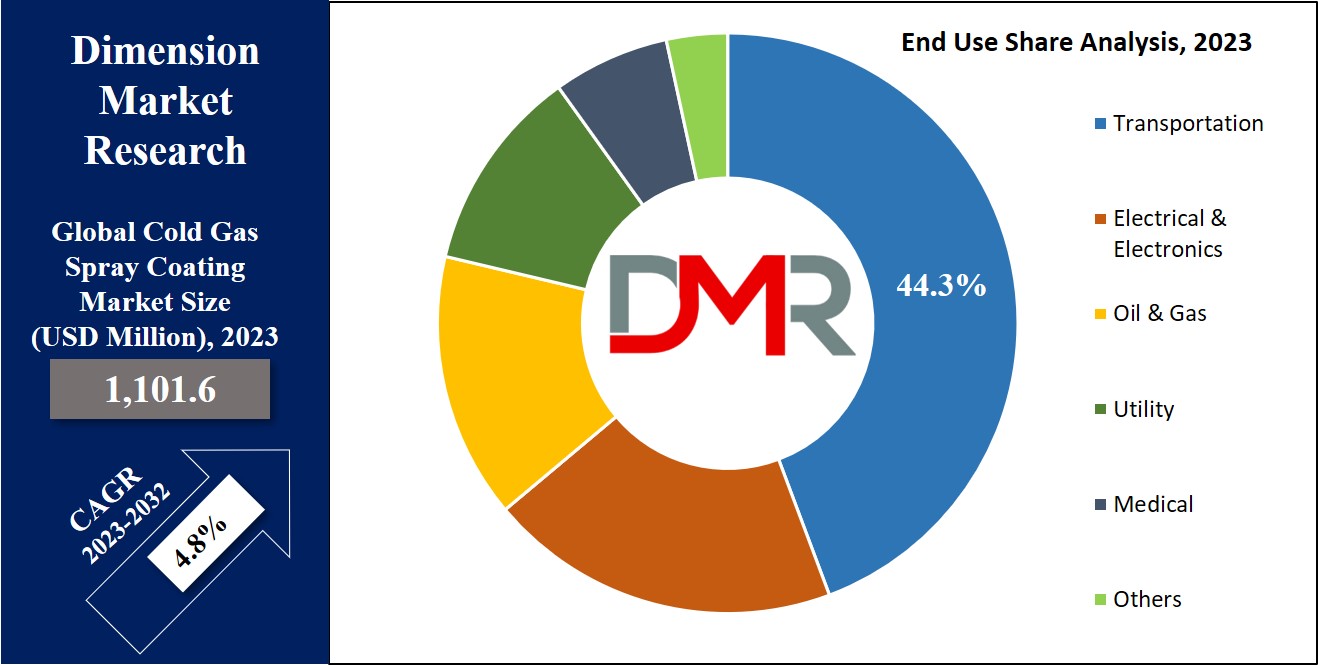

By End-Use

The segment of transportation dominates the market with a maximum share in 2023. This dominance can be credited to the rising acceptance of cold gas spray coatings for repairing & coating several parts in the automotive & aerospace sectors. In the automotive industry, cold gas spray coatings play an important role in improving the performance of vehicles by protecting them against fretting, wear, & corrosion. Several manufacturers in automotive sectors are shifting towards cold gas spray coatings as it is more economical & provide better quality. As governmental policies favor lightweight vehicles and preference is given to fuel efficiency, the demand for cold gas spray coatings is increasing.

Furthermore, in the aerospace sector, the cold gas spray coating technique has witnessed high demand for repairing & restoring housings of IDG utilized in civil aviation planes, for example, Airbus A330, Boeing 777 & Airbus A340, etc. The practicality & economic sustainability of this technology in dealing with & handling complex parts made of aluminum or magnesium alloys have set it as a preferred option in this field. Consequently, the cold gas spray coating sector has witnessed significant expansion, focusing on the requirements of the transportation sector & offering effective solutions for coating & repair tasks.

The Global Cold Gas Spray Coating Market Report is segmented on the basis of the following:

By Technology

- Low Pressure

- High Pressure

By End-Use

- Electrical & Electronics

- Electric Motors & Generations

- Electrical Contacts

- Circuit Boards

- Refrigeration units

- Power Electronic Heat Sinks

- Transformers

- Semi-Conductors & Displays

- Electro-plating

- Bus Bars Fluid Handling

- Transportation

- Aerospace

- Rocket Motor Nozzles

- Jet Engine parts

- Exhaust systems

- Satellites

- Pumps

- Gearboxes

- Landing Gears

-

- Automotive

- Exhaust Systems

- Pistons & Cylinders

- Manifolds

- Piston Ring Heat Exchangers

- Break

- Crankshafts

- Valve seats

- Heated Glass

- Oil & Gas

- Gate Valves

- Drilling Components

- Utility

- Turbo Chargers

- Solar Heat & Solar Energy Components

- Power Boilers

- Nuclear

- Gas & Hydro-Steam Turbine

- Medical

- Dental Implants

- Orthopedic Prostheses

- Others

- Others

- Agriculture

- Agricultural Harvesting Components

Regional Analysis

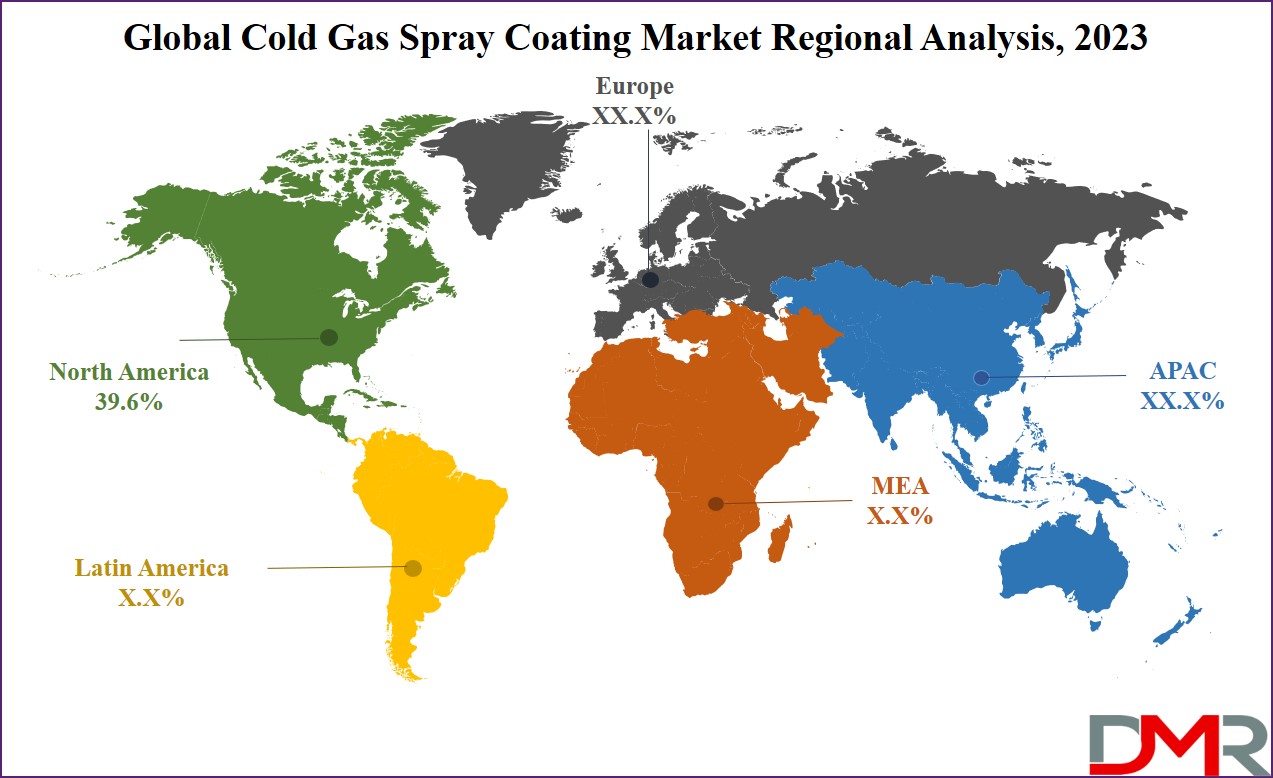

North America dominates the market, with a maximum share in 2023. The region's dominance is due to the supportive government policies that support the usage of lightweight & better-performing parts in the automotive sector as an environmentally friendly substitute to traditional metals. However, the changing attitude of several manufacturing sectors, especially the electrical & electronics sector, shifted to Asian nations such as China & India, because of their lower labor costs, which has affected the regional demand, especially in non-automotive end-use sectors.

Furthermore, Europe has also shown growth in the cold gas spray coatings market because of the presence of nations with more military & defense investments, like Germany, Russia, France, & the United Kingdom. The aerospace & defense sectors in these nations have shown keen interest in using cold gas spray coatings to protect aircraft & satellite components. Therefore, Europe offers lucrative opportunities for cold gas spray coating manufacturers to serve the particular needs of these high-spending sectors. With a rising desire for more advanced protective solutions, Europe’s market is anticipated to observe growth in this market.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The global market for cold gas spray coatings is characterized by consolidation, as it is dominated by a limited number of manufacturers worldwide. These companies are actively engaged in research and development to create new material systems with enhanced properties, encompassing a wide array of critical surface functionalities. The aerospace industry has been witnessing an increasing number of mechanical failures in components, leading to a surge in aftermarket repair and maintenance activities within the OEM market. This trend is expected to present considerable growth prospects for manufacturers of cold gas spray coatings in the foreseeable future.

Some of the prominent players in the Global Cold Gas Spray Coating Market are:

- Bodycote plc

- Flame Spray Technologies B.V

- Plasma Giken Co., Ltd.

- VRC Metal Systems, LLC

- ASB Industries, Inc.

- Curtiss- Wright Surface Technologies

- Praxair S.T. Technology, Inc.

- WWG Engineering Pte. Ltd.

- Concurrent Technologies Corporation

- Other Key Players

Recent Developments

- In March 2025, Praxair Technology introduced an advanced portable cold gas spray system aimed at rapid in-field aerospace and automotive component repairs, expanding their cold spray services portfolio.

- In February 2025, Linde announced a major new investment round to scale up production and R&D for its cold spray additive manufacturing innovation, “Linspray Connect,” to broaden aviation and energy sector adoption.

- In December 2024, Oerlikon successfully completed the acquisition of German surface engineering firm Riri, strengthening its capabilities in high-performance cold spray coating solutions for industrial applications.

- In November 2024, Saint-Gobain launched a new cold spray coating line targeting electric vehicle manufacturing, focusing on lightweight, high-durability automotive parts for global OEMs.

- In October 2024, Impact Innovations secured significant venture funding to accelerate development of automated cold gas spray equipment, with the goals of boosting scalability and reducing deployment costs.

- In September 2024, a strategic merger between two U.S.-based regional cold spray technology firms created a combined entity to offer end-to-end cold gas spray solutions for aerospace MRO clients.

Report Details

| Report Characteristics |

| Market Size (2023) |

USD 1,101.6 Mn |

| Forecast Value (2032) |

USD 1,677 Mn |

| CAGR (2023–2032) |

4.8% |

| Historical Data |

2017 – 2022 |

| Forecast Data |

2023 – 2032 |

| Base Year |

2022 |

| Estimate Year |

2023 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Technology (Low Pressure and High Pressure), By End-Use (Electrical & Electronics, Transportation, Oil & Gas, Utility, Medical, and Others). |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA |

| Prominent Players |

Bodycote plc, Flame Spray Technologies B.V, Plasma Giken Co., Ltd., VRC Metal Systems, LLC, ASB Industries, Inc., Curtiss-Wright Surface Technologies, Praxair S.T. Technology, Inc., WWG Engineering Pte. Ltd., Concurrent Technologies Corporation, and Other Key Players. |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |

Frequently Asked Questions

The Global Cold Gas Spray Coating Market is expected to reach a valuation of USD 1,101.6 Million in

2023.

The Global Cold Gas Spray Coating Market is expected to grow at a steady compound annual growth rate (CAGR) of 4.8% from 2023 to 2032.

North America dominates the market, accounting for a substantial revenue share of 39.6% in 2023.

Some of the prominent players in the Global Gas Spray Coating Market include Bodycote plc, Flame

Spray Technologies B.V, Plasma Giken Co., Ltd., VRC Metal Systems, LLC, and others.

Contents

1.1. Objectives of the Study

1.3. Market Definition and Scope

2. Cold Gas Spray Coating Market Overview

2.1. Global Cold Gas Spray Coating Market Overview by Type

2.2. Global Cold Gas Spray Coating Market Overview by Application

3. Cold Gas Spray Coating Market Dynamics, Opportunity, Regulations, and Trends Analysis

3.1.1. Cold Gas Spray Coating Market Drivers

3.1.2. Cold Gas Spray Coating Market Opportunities

3.1.3. Cold Gas Spray Coating Market Restraints

3.1.4. Cold Gas Spray Coating Market Challenges

3.2. Emerging Trend/Technology

3.4. PORTER'S Five Forces Analysis

3.6. Opportunity Map Analysis

3.11. Supply/Value Chain Analysis

3.12. Covid-19 & Recession Impact Analysis

3.13. Product/Brand Comparison

4. Global Cold Gas Spray Coating Market Value ((US$ Mn)), Share (%), and Growth Rate (%) Comparison by Product, 2017-2032

4.1. Global Cold Gas Spray Coating Market Analysis by Product: Introduction

4.2. Market Size and Forecast by Region

5. Global Cold Gas Spray Coating Market Value ((US$ Mn)), Share (%), and Growth Rate (%) Comparison by Application, 2017-2032

5.1. Global Cold Gas Spray Coating Market Analysis by Application: Introduction

5.2. Market Size and Forecast by Region

6. Global Cold Gas Spray Coating Market Value ((US$ Mn)), Share (%), and Growth Rate (%) Comparison by Region, 2017-2032

6.1.1. North America Cold Gas Spray Coating Market: Regional Analysis, 2017-2032

6.2.1. Europe Cold Gas Spray Coating Market: Regional Trend Analysis

6.3.1. Asia-Pacific Cold Gas Spray Coating Market: Regional Analysis, 2017-2032

6.3.1.7. Rest of Asia-Pacific

6.4.1. Latin America Cold Gas Spray Coating Market: Regional Analysis, 2017-2032

6.4.1.5. Rest of Latin America

6.5. Middle East and Africa

6.5.1. Middle East and Africa Cold Gas Spray Coating Market: Regional Analysis, 2017-2032

7. Global Cold Gas Spray Coating Market Company Evaluation Matrix, Competitive Landscape, Market Share Analysis, and Company Profiles

7.1. Market Share Analysis

7.3.2. Financial Highlights

7.3.5. Key Strategies and Developments

7.4.2. Financial Highlights

7.4.5. Key Strategies and Developments

7.5. Reckitt Benckiser Group PLC

7.5.2. Financial Highlights

7.5.5. Key Strategies and Developments

7.6.2. Financial Highlights

7.6.5. Key Strategies and Developments

7.7.2. Financial Highlights

7.7.5. Key Strategies and Developments

7.8. GOJO Industries, Inc.

7.8.2. Financial Highlights

7.8.5. Key Strategies and Developments

7.9.2. Financial Highlights

7.9.5. Key Strategies and Developments

7.10.2. Financial Highlights

7.10.3. Product Portfolio

7.10.5. Key Strategies and Developments

7.11. Whiteley Corporation

7.11.2. Financial Highlights

7.11.3. Product Portfolio

7.11.5. Key Strategies and Developments

7.12.2. Financial Highlights

7.12.3. Product Portfolio

7.12.5. Key Strategies and Developments

7.13. Evonik Industries, AG

7.13.2. Financial Highlights

7.13.3. Product Portfolio

7.13.5. Key Strategies and Developments

7.14.2. Financial Highlights

7.14.3. Product Portfolio

7.14.5. Key Strategies and Developments

8. Assumptions and Acronyms