The Egg Processing and Equipment Market refers to a sector specializing in the design, deployment, and use of advanced machinery and technologies designed to efficiently process, handle, and package eggs. This market includes equipment for egg collection, sorting, washing, and packaging that has been created to increase operational efficiencies while meeting consumer demands for quality and safety. Key trends within this market include automation technology such as AI-driven technologies as well as environmentally sustainable packaging solutions - understanding this market fully is crucial in optimizing production workflows while lowering operational costs as well as maintaining competitive edge within this dynamic food industry!

The Egg Processing and Equipment Market is currently experiencing dramatic transformation driven by technological innovation and changing consumer preferences. As global egg consumption increases, so too does demand for efficient processing solutions with high capacity and efficiency - such as AI-powered sorting systems or high-speed packaging technologies to enhance operational efficiencies and accuracy while meeting stringent food safety standards. Automation plays a pivotal role in this transformational journey. Automation plays a central role in the evolution of this sector as its use advances further with innovations like these providing operational scalability while meeting food safety regulations requirements in line with food standards compliance regulations.

Regionally, North America and Europe lead the market due to robust food processing infrastructures and widespread adoption of technologies. Meanwhile, Asia-Pacific is emerging as an attractive growth area, driven by rapid urbanization, rising disposable incomes, and an expanding food sector. Furthermore, its increasing demand for efficient processing solutions indicates its potential as a driving factor of global market expansion.

Key Takeaways

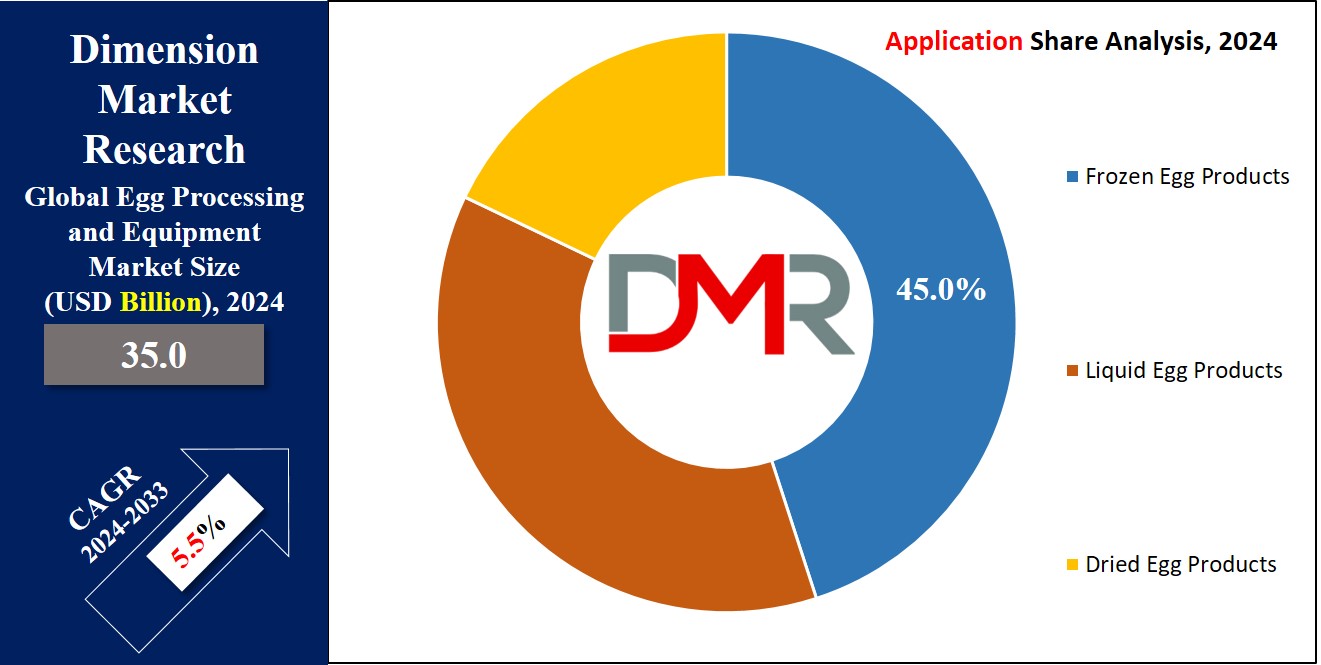

- Market Value and Growth Forecast: The Egg Processing and Equipment Market is projected to grow from USD 35.0 billion in 2024 to USD 56.7 billion by 2033, reflecting a robust CAGR of 5.7% during the forecast period.

- Dominant Product Types: Frozen Egg Products led the market in 2023 with a 45% share, followed by Liquid Egg Products at 35%, and Dried Egg Products holding a 20% share.

- Regional Leadership: The Asia-Pacific region, particularly driven by China, dominates the market, contributing approximately 50% of global egg production. This region's market valuation was significant, supported by rapid urbanization and increased demand.

- Key Trends: Automation, including AI-driven technologies and environmentally sustainable packaging solutions, is transforming the sector. The rising consumer demand for convenience foods and health-conscious products is driving innovation.

- Growth Drivers: Government support, product development, and market expansion in emerging regions are crucial factors driving market growth. Investment in modern equipment and technological advancements supports these developments.

Use Cases

- High-Capacity Production: Automated, high-speed processing lines are essential for meeting growing global egg demand, particularly in the Asia-Pacific region, while ensuring efficiency and compliance with food safety standards.

- Versatile Equipment: Customizable processing solutions are needed to handle various egg products like liquid, frozen, and dried, catering to diverse applications in baking, confectionery, and condiments.

- Eco-Friendly Packaging: Sustainable packaging solutions are increasingly important, with equipment designed for biodegradable or recyclable materials helping manufacturers meet environmental regulations and consumer preferences.

- Food Safety Enhancement: Advanced cleaning and contamination prevention systems are critical for maintaining high food safety standards and ensuring product quality.

- Emerging Market Growth: Expanding egg processing infrastructure in developing regions supports local production and meets rising demand, driving market growth and equipment adoption.

Driving Factors

Government Support and Regulations

Government support and stringent regulations play a critical role in shaping the Egg Processing and Equipment Market. Compliance with high food safety and hygiene standards drives demand for advanced processing technologies that meet these regulations. Stricter regulations regarding food safety and quality have driven producers to invest in modern equipment that meets stringent standards, thus encouraging market expansion. Government incentives for adopting eco-friendly practices and advanced technologies also spur investment in innovative processing and packaging solutions, helping maintain high operational standards while encouraging the adoption of groundbreaking innovations for a stable market environment.

Product Development and Variety

Product innovation and variety development play a vital role in expanding the Egg Processing and Equipment Market. As consumer preferences evolve towards convenience and high-quality egg products, manufacturers are creating diverse and advanced processing solutions to meet these demands. Innovations such as AI-enhanced sorting systems, high-speed packaging lines, and advanced cleaning technologies address the increasing need for efficiency and precision in egg processing. Aiming at variety and innovation, equipment must be designed to accommodate various kinds of egg products ranging from liquid and powdered varieties to specialty eggs - increasing market applications and broadening applications. Furthermore, customizable modular equipment enables producers to respond more rapidly to changing market needs, driving further market expansion.

Market Expansion in Emerging Regions

Egg Processing and Equipment Market expansion in developing regions is a driving force of market expansion. Rapid urbanization, rising disposable incomes, and growing consumer interest in processed food products such as those found in Asia-Pacific provide new avenues for market expansion. Asia-Pacific egg products market is experiencing rapid expansion as food sector expansion drives increased consumer interest for high-quality egg products. Regional growth is enabled by investments made to modernize food processing infrastructures and meet rising egg processing solutions demand. As developing regions continue to embrace advanced technologies, they provide significant opportunities for market expansion and equipment sales growth.

Growth Opportunities

Rising Demand for Convenience Foods

2023 will see an unprecedented global egg processing and equipment market driven by consumer preference for convenience foods, with increasingly busy consumer lifestyles prompting a shift toward ready-to-eat and easy-to-prepare egg products. To meet this increasing trend efficiently and meet evolving consumer tastes, sophisticated processing and packaging equipment is needed which supports automation, high-speed production, innovative packaging solutions as well as automation technologies - driving the market growth.

Product Development and Customization

Product development and customization represent a key opportunity within the market. Consumers increasingly require egg products tailored specifically to individual diets; as a result, industries are investing in cutting-edge technology with increased functionality and adaptability, such as customizable processing lines or modular equipment that handles different egg types or formats; this trend not only meets diverse consumer demands but also opens new market segments to drive innovation and expansion within the sector.

An Increased Focus on Food Safety

Food safety will play an integral part in shaping the market in 2023. Stringent regulations and increasing consumer awareness surrounding hygiene have caused egg producers to invest in advanced equipment to uphold high cleanliness and quality standards, such as sophisticated cleaning technologies, contamination prevention systems, and real-time monitoring solutions. By adopting such innovations manufacturers not only ensure compliance with regulations but also enhance product quality while cultivating consumer trust.

Key Trends

Processed Egg Products Can Be Utilized for Different Purposes

2023 will see a surge in egg processing applications worldwide. From food manufacturing to healthcare, processed eggs of various forms such as liquid, powdered, or frozen varieties are increasingly being utilized in applications across industries ranging from food manufacturing to healthcare. This trend can be explained by their versatility and convenience which allow for their inclusion in numerous baked goods, sauces, or dietary supplements products. As industries attempt to take advantage of processed egg's functional benefits by employing more processed egg formats with high-quality standards requirements; demand for advanced processing equipment capable of accommodating multiple egg formats while meeting stringent quality requirements is growing significantly.

Consumer Trends on Health-Conscious Lifestyles

Health-focused consumer trends are having a tremendous effect on the Egg Processing and Equipment Market in 2023. As people become more health conscious, they increasingly desire egg products with nutritional advantages like omega-3 fatty acids or those free from antibiotics and hormones - something egg processors must adapt to to satisfy customer preferences for such items. With more consumers demanding such benefits from egg products than ever before, there is now increased demand for processing equipment that ensures production meets strict health and safety regulations while at the same time improving nutritional profiles and purity standards of such items while increasing production of specialty egg products - something egg processors must adapt accordingly!

Product Innovation and Customization Services offered

Product innovation and customization have emerged as two key trends this year in the egg market. As consumer tastes shift, egg producers are responding by creating versatile processing systems capable of tailoring offerings specifically to different culinary applications and dietary restrictions. They must meet rising consumer expectations for diverse and high-quality egg products by developing versatile processing systems with customizable and modular capabilities that enable customized production offerings suited for various egg types, integration with advanced processing technologies, and adapting to fluctuating market needs - these innovations must remain competitive to remain relevant in meeting them!

Restraining Factors

Fluctuating Raw Material Prices

Fluctuating raw material prices pose a formidable obstacle to the Egg Processing and Equipment Market. Egg prices, an essential input in egg processing, can become volatile due to factors such as feed costs, disease outbreaks, supply chain disruptions, and price volatility - impacting overall manufacturing costs as production costs and pricing pressures escalate. As raw material costs change frequently it becomes challenging for producers to maintain stable profit margins while passing along costs to consumers without increasing production costs or pricing pressures - as such fluctuation discourages investment in new technologies or expansion projects which ultimately inhibit market expansion growth and innovation.

Oversaturation in Established Markets

Egg Processing and Equipment Market in developed regions has reached saturation, restricting growth. Mature markets in North America and Europe have reached high levels of penetration with most large-scale egg producers already using sophisticated processing equipment, creating an overly saturated competitive environment where growth is driven more by replacement cycles than new market entry opportunities - potentially slowing revenue growth while diminishing incentives for manufacturers to invest in cutting-edge technologies and explore novel business avenues.

Lack of Infrastructure in Developing Regions

Lack of infrastructure in developing regions presents a substantial barrier to the expansion of the Egg Processing and Equipment Market. Many emerging economies do not possess adequate facilities for egg production, processing, distribution, or processing equipment adoption. Poor infrastructure compromises processing operations, leading to higher operational costs and reduced productivity. Access to modern technologies and financial resources limits producers in these regions from investing in cutting-edge equipment, limiting market growth while diminishing equipment manufacturers' opportunities, particularly those operating in regions with underdeveloped infrastructure.

By Type

Frozen Egg Products was the clear leader of the Product Type segment of the Egg Processing and Equipment Market in 2023, commanding roughly 45% market share. This indicates the rising popularity of frozen egg products as their extended shelf life, convenience, and versatility make them increasingly preferred by food manufacturers and consumers alike. Their increasing use has necessitated large investments in processing equipment in support of this sector's development.

Liquid Egg Products followed closely, accounting for around 35% of market share. Their prevalence can be seen in food service and industrial applications where consistency, ease of use, and reduced preparation times are critical components. Furthermore, innovations designed to extend shelf life by decreasing bacterial contamination levels or enhancing product stability all play an integral part in supporting this segment's market presence and growth.

Dried Egg Products make up approximately 20% of the Egg Processing and Equipment Market and play an important part. Their concentrated form and long shelf life make them especially helpful in specific applications like bakery products, snacks, powdered mixes, and powdered mixes. Their growth can be attributed to innovations in drying technologies as well as rising global food supply chain demands for non-perishable ingredients that don't expire quickly; their role contributes significantly to overall dynamics within this sector of the industry. Despite being less prominent than other segments such as the fresh egg products segment, dried egg products still contribute greatly towards overall dynamics within this sector of the Egg Processing Equipment Market overall dynamics by contributing niche markets and applications that contribute greatly significantly to dynamics present within this sector of market dynamics overall dynamics - adding significantly contributing.

By Application

Baking was the clear market leader in 2023 in terms of product type segment of the Egg Processing and Equipment Market for Eggs Processing Solutions & Equipment, accounting for an approximate 50% market share. This substantial share reflects eggs' essential role in baking processes - providing texture, structure and consistency across a range of baked products from bread to pastries. Convenience baking practices as well as rising artisanal baking practices continue to drive significant demand for customized egg processing solutions tailored specifically for baking sector businesses, including innovations like mixing homogenizing and emulsification technologies.

The Condiment Industry was next, accounting for approximately 25% of the market share. Eggs play a vital role in many condiments and sauces like mayonnaise and hollandaise due to their emulsifying properties; their increased consumer demand has stimulated investments in advanced processing equipment designed to ensure product quality and consistency.

Confectionery accounted for roughly 15% of market share. Eggs play a crucial role in confectionery products such as cakes, cookies, and cream fillings; their textures and flavors play an integral part in how confectioneries taste and are enjoyed. New egg processing equipment innovation seeks to maximize efficiency and quality production processes per gourmet and artisanal trends.

The Other category, consisting of niche applications and smaller segments, represented 10% of the egg product market in 2014. This sector encompasses egg products used in non-traditional applications or emerging food trends as well as their uses in specialty applications and formulations that drive innovation and diversify market penetration. Though only accounting for 10%, its share continues to expand as manufacturers explore innovative uses for egg products which drive innovation and diversify their markets.

The Egg Processing and Equipment Market Report is segmented based on the following:

By Type

- Frozen Egg Products

- Liquid Egg Products

- Dried Egg Products

By Application

- Dairy

- Condiment Industry

- Baking

- Confectionary

- Others

Regional Analysis

Asia Pacific Region was the clear leader in Egg Processing and Equipment Market by 2023, driven by China's unparalleled egg production - approximately 50% of global output - which translated to strong demand for processing equipment with China accounting for USD XX billion market valuation and technological innovations such as investments or partnerships aimed at increasing processing efficiency or automating processes; India, Japan and South Korea quickly expanding markets also being key growth drivers of regional market dynamics.

North America follows closely, distinguished by an advanced food processing infrastructure and a strong focus on technological innovation. Together, the U.S. and Canada had a market valuation of USD XX billion by 2023 due to their strong commitment to food safety and efficiency as well as adopting cutting-edge egg processing technologies.

Europe held an estimated USD XX billion valuation by 2023. Market growth was fuelled by stringent food safety regulations and investments in sustainable and energy-efficient processing technologies. Key players in Europe sought to align themselves with these regulations and advance processing technologies to maintain competitiveness.

Middle East & Africa markets, despite being relatively young, are experiencing impressive growth with market revenues of USD XX billion in 2023. This increase can be attributed to rising egg consumption as well as investments made into modern processing technology that improves food safety and processing efficiency.

By Region

North America

Europe

- Germany

- U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

C-level executives play an integral part in driving innovation in the Egg Processing and Equipment Market. Their influence extends far beyond their organizations; these leaders play an instrumental role in adopting technological advances such as AI and automation within their organizations and optimizing operations to remain competitive within an ever-evolving market. Their strategic vision ensures their firms meet increasing demands while meeting industry challenges effectively.

Marketing and Brand Managers play an essential role in setting products apart in an ever-competitive landscape. Their responsibilities include developing engaging marketing strategies that highlight the benefits of advanced egg processing technologies while meeting consumer expectations for sustainability and efficiency. Their efforts in crafting compelling brand narratives and running engaging promotional campaigns are key to increasing market visibility and driving consumer interest.

Procurement Managers and Production Managers play vital roles in ensuring a smooth operation of supply chains and manufacturing processes, such as procuring high-quality materials at cost-efficient rates while overseeing product quality production processes. Technical Personnel also play an essential role, supporting equipment performance while guaranteeing reliability for customer satisfaction and reliability for reliable equipment operation. Distributors facilitate market reach by efficiently managing logistics while expanding access to advanced technologies thereby supporting market expansion and accessibility - each role is essential in supporting dynamic markets growth and their ultimate success.

Some of the prominent players in the Global Egg Processing and Equipment Market are:

- C-Level Executives

- Marketing Manager, Brand Manager, Product Manager

- Sales Manager, Sales Officer, Regional Sales Manager, Country Manager

- Procurement Manager

- Production Manager

- Technical Personnel

- Distributors

Recent developments

- In 2022, July: New equipment designs for sustainable packaging emerged, featuring biodegradable and recyclable materials to meet both environmental regulations and consumer demand for eco-friendly products.

- In 2023, January: High-speed modular processing lines were released that offer versatile handling of various egg products and enable rapid customization and scaling capabilities.

- In 2023, April: To meet stringent food safety standards, improved cleaning and contamination prevention technologies have been created, such as advanced sanitization systems and real-time monitoring tools.

- In 2023, October: Automation technologies for egg breaking, mixing, and packaging were implemented, increasing efficiency while simultaneously decreasing manual labor needs.

- In 2024, March: New advances in drying technologies are revolutionizing efficiency and quality for dried egg products, meeting market demand for long-shelf life ingredients.

Report Details

| Report Characteristics |

| Market Size (2023) |

USD 35.0 Billion |

| Forecast Value (2032) |

USD 56.7 billion |

| CAGR (2023-2032) |

5.5% |

| Historical Data |

2018 – 2023 |

| Forecast Data |

2024 – 2033 |

| Base Year |

2023 |

| Estimate Year |

2024 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Type(Frozen Egg ProductsLiquid Egg Products, Dried Egg Products), By Application(Dairy, Condiment Industry, Baking, Confectionary, Others) |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia- Pacific– China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA

|

| Prominent Players |

C-Level Executives, (Marketing Manager, Brand Manager, Product Manager), (Sales Manager, Sales Officer, Regional Sales Manager, Country Manager), Procurement Manager, Production Manager, Technical Personnel, Distributors |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |