Market Overview

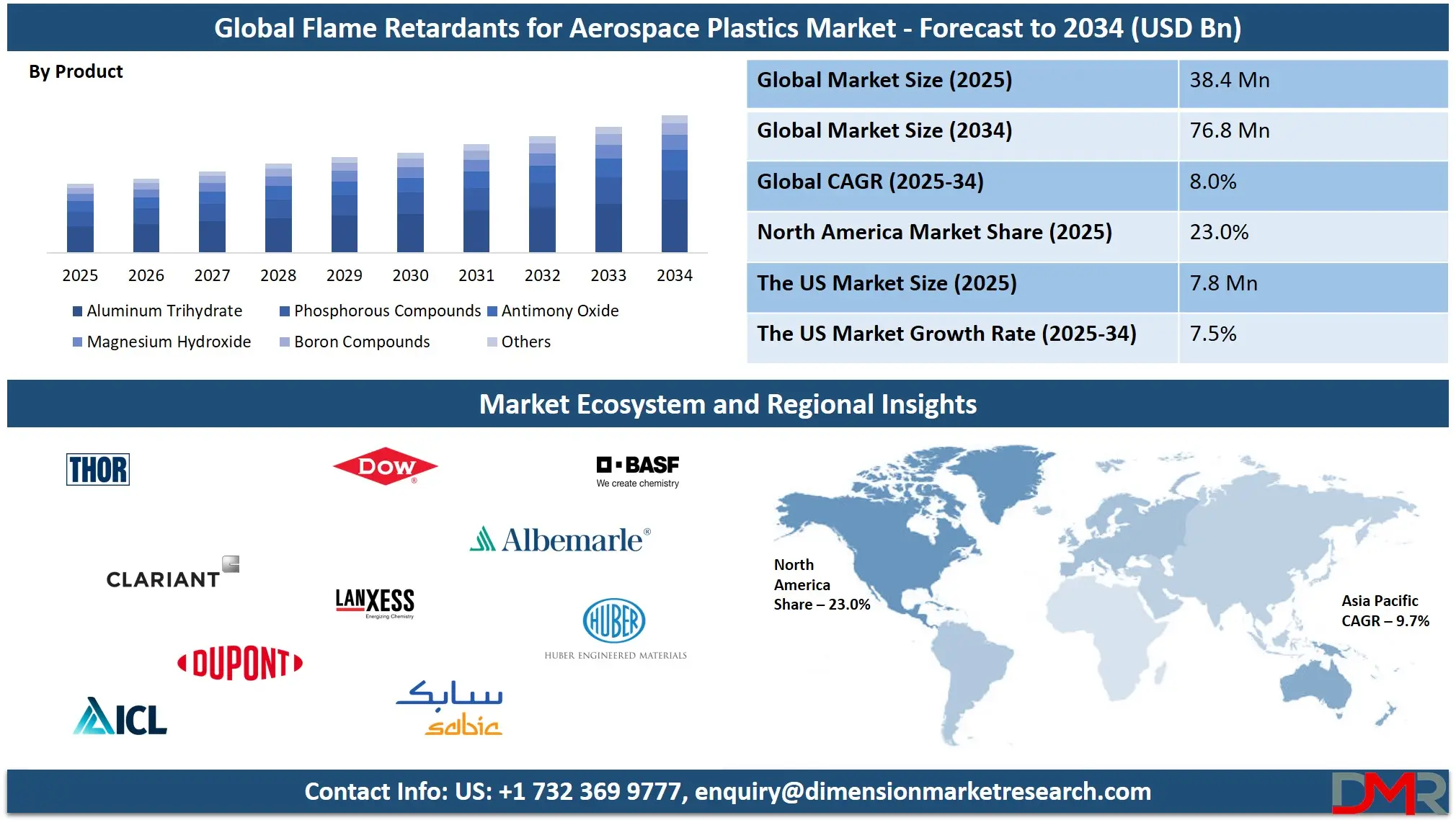

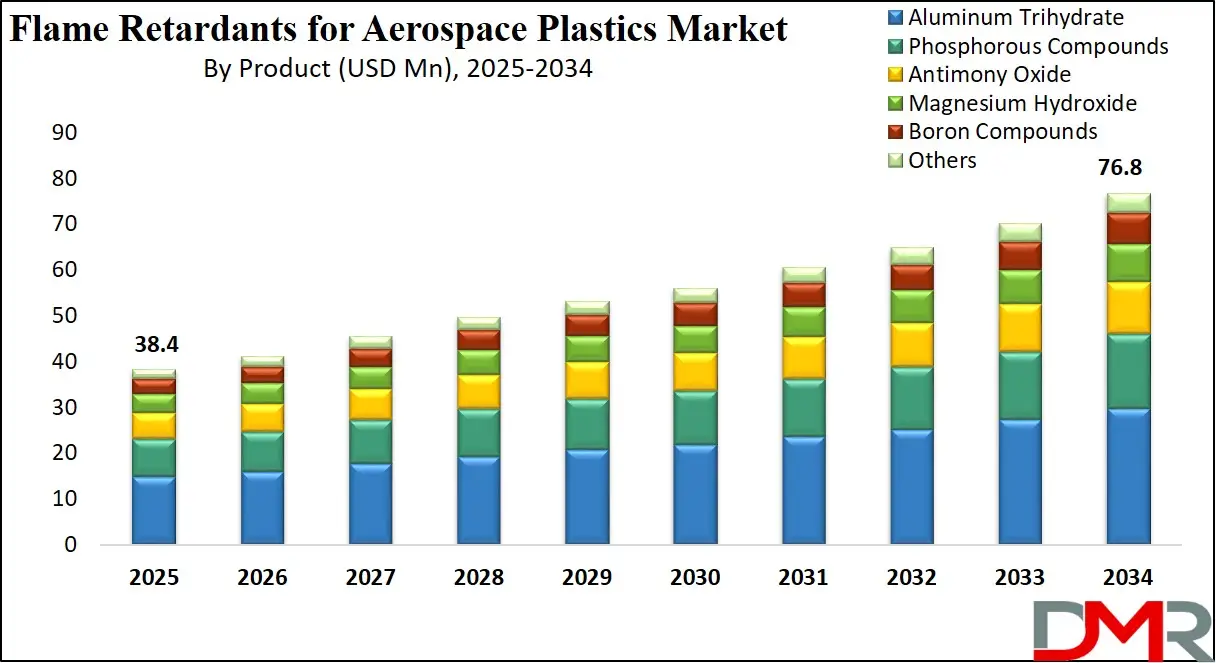

The Global Flame Retardants for Aerospace Plastics Market size is projected to reach USD 38.4 million in 2025 and grow at compound annual growth rate of 8.0% from there until 2034 to reach a value of USD 76.8 million.

Flame retardants for aerospace plastics are chemical substances added to plastic materials used in the aerospace industry to prevent or slow down fire. These plastics are found in parts like aircraft interiors, panels, seats, wiring insulation, and structural components. In the event of a fire, flame retardants reduce the spread of flames and give people more time to escape, which is critical for safety. The aerospace sector uses materials that must meet strict fire, smoke, and toxicity (FST) standards, and flame retardants help meet these regulations.

Over the years, the demand for flame retardants in aerospace plastics has increased steadily. This growth is driven by rising aircraft production, modernization of aging fleets, and growing air passenger traffic. Aerospace companies are investing in lighter, stronger, and more heat-resistant materials, and plastic composites are a popular choice. Since plastics are naturally flammable, flame retardants are necessary to make them safe for use in aircraft. Both commercial and military aviation sectors rely on these materials for building safer aircraft components.

One clear trend is the shift from halogenated flame retardants to non-halogenated ones. Halogen-based chemicals, although effective, are being phased out due to environmental and health concerns. Newer alternatives are more eco-friendly and release fewer toxic fumes when exposed to fire. Another trend is the increasing use of high-performance plastics such as polyetheretherketone (PEEK) and polyimides, which naturally resist heat and flame but still benefit from added flame retardants for extra safety.

The industry has seen innovations in flame retardant technology, with a focus on nanomaterials and phosphorus-based compounds. These materials provide high fire resistance without compromising mechanical properties. Researchers and manufacturers are also developing multifunctional materials that are both flame retardant and lightweight, which is essential for improving aircraft fuel efficiency. Advances in additive manufacturing and 3D printing are also expanding how these materials can be used in aerospace.

Recent years have seen strict regulations on fire safety in aircraft interiors, pushing aerospace companies to adopt more advanced flame retardant solutions. Agencies like the FAA and EASA have introduced stricter testing standards. Several large aerospace events and expos, such as the Paris Air Show, have highlighted new materials that meet updated fire safety norms. These events often serve as platforms for introducing next-generation flame-retardant materials.

The aerospace industry's focus on safety, efficiency, and sustainability is shaping the future of flame retardants for plastics. As aircraft become more advanced and lightweight materials gain preference, the need for effective, non-toxic, and high-performing flame retardants will only grow. Environmental regulations, material innovations, and industry standards will continue to influence product development. Overall, flame retardants are not just additives—they are essential tools for ensuring fire safety in modern aerospace design.

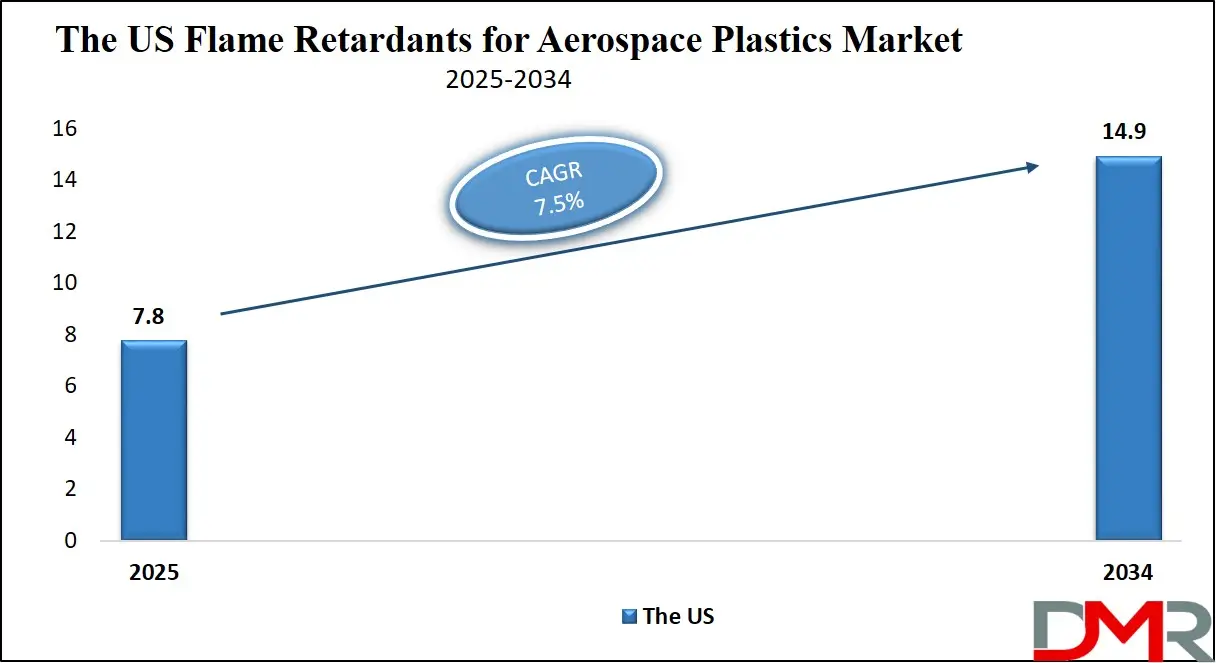

The US Flame Retardants for Aerospace Plastics Market

The US Flame Retardants for Aerospace Plastics Market size is projected to reach USD 7.8 million in 2025 at a compound annual growth rate of 7.5% over its forecast period.

The US plays a major role in the flame retardants for aerospace plastics market due to its strong aerospace industry, advanced R&D capabilities, and strict safety regulations. As home to several major aircraft manufacturers and defense contractors, the US drives high demand for flame-retardant materials that meet stringent fire, smoke, and toxicity standards. The country also leads in the development of innovative, eco-friendly flame retardants, thanks to its well-established chemical and material science sectors.

Regulatory bodies like the FAA enforce rigorous testing and certification processes, further encouraging the use of advanced flame retardants. Additionally, ongoing investments in commercial aviation, space exploration, and military aircraft projects continue to support the growth and evolution of the US flame retardants market.

Europe Flame Retardants for Aerospace Plastics Market

Europe Flame Retardants for Aerospace Plastics Market size is projected to reach USD 18.2 million in 2025 at a compound annual growth rate of 7.2% over its forecast period.

Europe plays a significant role in the flame retardants for aerospace plastics market, driven by its strong presence in commercial aviation, aerospace manufacturing, and sustainability-focused regulations. Countries like Germany, France, and the UK are home to leading aircraft and component producers that demand high-performance, fire-resistant materials. The European Union enforces strict fire safety and environmental standards, encouraging the use of halogen-free and eco-friendly flame retardants.

Europe's commitment to green innovation has led to increased research in bio-based and recyclable flame retardant systems. In addition, modernization of older aircraft fleets and expansion of regional air travel are boosting demand for compliant plastic components. With its regulatory leadership and focus on material innovation, Europe remains a key player in shaping market trends.

Japan Flame Retardants for Aerospace Plastics Market

Japan Flame Retardants for Aerospace Plastics Market size is projected to reach USD 1.9 million in 2025 at a compound annual growth rate of 8.1% over its forecast period.

Japan plays a vital role in the flame retardants for aerospace plastics market, known for its advanced materials and technology innovation. Japan’s aerospace plastics market reached approximately USD 58.9 million in 2024, with strong growth expected through 2030, driven especially by high-performance polymers like PEEK. The country leverages its skilled R&D capabilities and integrated chemical manufacturing base to develop and supply specialized flame retardant compounds—such as antimony oxide, aluminum trihydrate, organophosphates, and boron-based additives—for aerospace-grade plastics.

These materials meet rigorous international fire safety standards (FAR/JAR 25.853, ASTM E162), supporting applications in aircraft interiors, composites, and structural parts. In addition, Japan’s demand is boosted by both new aircraft production and fleet modernization, including small jets and defense platforms. Looking ahead, Japan’s focus on sustainable, halogen-free flame retardants aligns well with global trends, reinforcing its position as a key innovation hub in aerospace safety materials.

Flame Retardants for Aerospace Plastics Market: Key Takeaways

- Market Growth: The Flame Retardants for Aerospace Plastics Market size is expected to grow by USD 35.6 million, at a CAGR of 8.0%, during the forecasted period of 2026 to 2034.

- By Product: The aluminum trihydrate is anticipated to get the majority share of the Flame Retardants for Aerospace Plastics Market in 2025.

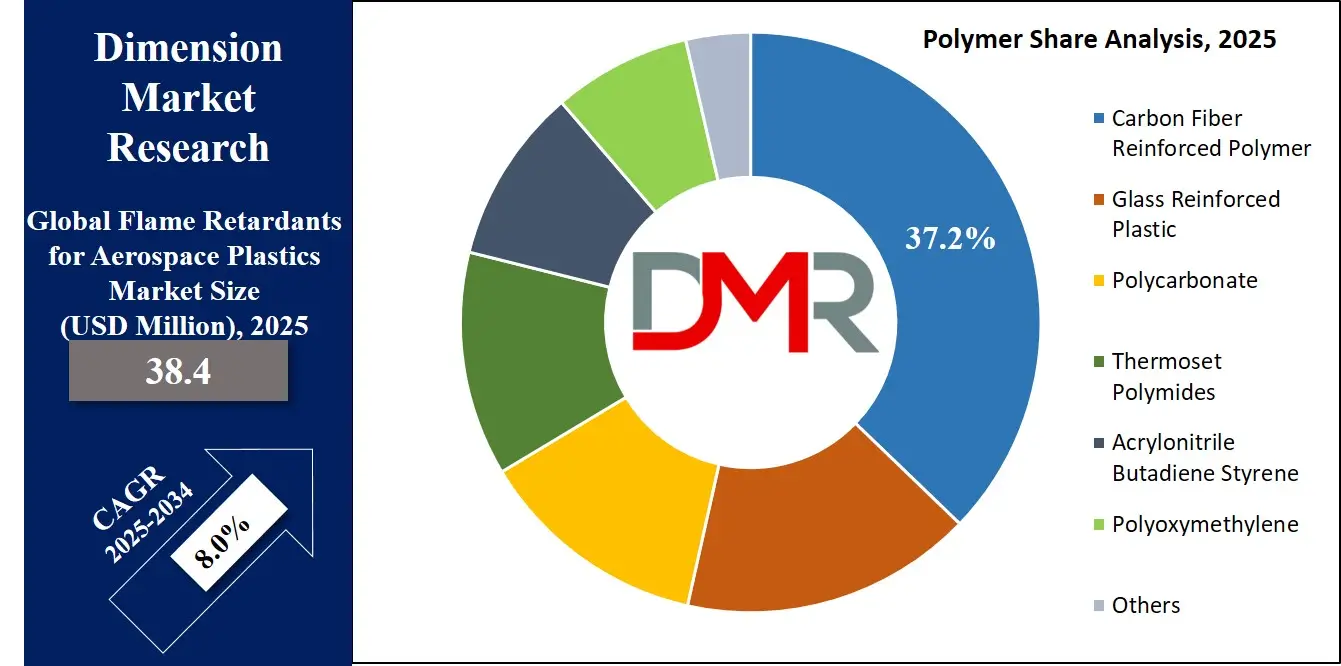

- By Polymer: The Carbon fiber reinforced polymer segment is expected to get the largest revenue share in 2025 in the Flame Retardants for Aerospace Plastics Market.

- Regional Insight: Europe is expected to hold a 47.5% share of revenue in the Global Flame Retardants for Aerospace Plastics Market in 2025.

- Use Cases: Some of the use cases of Flame Retardants for Aerospace Plastics include aircraft interiors, structural components, and more.

Flame Retardants for Aerospace Plastics Market: Use Cases

- Aircraft Interiors: Flame retardants are used in interior components like seat cushions, wall panels, overhead bins, and floor coverings. These materials must meet strict fire resistance standards to reduce the risk of fire spreading inside the cabin. They help ensure passenger safety during emergencies by limiting smoke and toxic gas release.

- Wiring and Cable Insulation: Electrical wiring and cables in aircraft are coated with flame-retardant plastic insulation. This prevents fires caused by short circuits or overheating. The flame retardants help maintain circuit integrity and delay ignition in high-temperature conditions.

- Structural Components: Plastic composites reinforced with flame retardants are used in lightweight structural parts of aircraft. These include interior brackets, ducts, and housings. The materials offer strength and fire resistance without adding much weight, which supports fuel efficiency.

- Cargo Compartments and Linings: Flame-retardant plastics are used in cargo hold linings and barriers to contain and slow down fires from luggage or freight. These materials are designed to withstand high heat and help protect passengers and crew by isolating fire-prone areas.

Market Dynamic

Driving Factors in the Flame Retardants for Aerospace Plastics Market

Rising Demand for Lightweight and Fire-Safe Materials in Aircraft Production

One of the key growth drivers of the flame retardants for aerospace plastics market is the increasing demand for lightweight, high-performance materials in aircraft manufacturing. As airlines and aircraft manufacturers focus on improving fuel efficiency and reducing emissions, they are replacing heavier metal components with lightweight plastic composites. However, plastics are inherently flammable, which creates a strong need for effective flame retardant additives to ensure safety.

These flame retardants enable manufacturers to meet strict fire, smoke, and toxicity (FST) standards without compromising weight advantages. With the steady growth in both commercial aviation and defense aerospace sectors, especially in emerging markets, the use of fire-safe plastic components is rising. This shift supports the consistent demand for advanced flame retardant materials globally.

Stricter Safety Regulations and Industry Standards Worldwide

Another major growth factor is the tightening of global fire safety regulations in the aerospace sector. Aviation authorities and regulatory bodies like the FAA and EASA have introduced more rigorous testing and certification standards for materials used in aircraft interiors. These updated rules require components to demonstrate high flame resistance, low smoke production, and minimal toxic gas emissions during combustion.

To meet these standards, manufacturers must adopt more effective and reliable flame retardant solutions in their plastic parts. This is pushing suppliers and chemical companies to innovate and develop non-toxic, halogen-free flame retardants that perform well under extreme conditions. As compliance becomes more critical for certification and global market access, the demand for compliant flame retardant plastics is seeing strong upward momentum.

Restraints in the Flame Retardants for Aerospace Plastics Market

Health and Environmental Concerns Over Certain Flame Retardants

One of the key restraints in the flame retardants for aerospace plastics market is the growing concern about the health and environmental impact of some traditional flame retardant chemicals, especially halogenated compounds. These substances have been linked to potential toxicity, bioaccumulation, and environmental persistence. As awareness increases and environmental regulations become stricter, manufacturers are being forced to phase out certain chemicals, which limits material choices and increases the cost of developing alternatives.

The process of switching to safer, eco-friendly flame retardants requires significant research, testing, and approval. This transition period slows down product development and can create supply chain challenges. In some regions, bans on specific substances also disrupt global supply consistency and market adoption.

High Cost and Complex Certification Requirements

The flame retardants for aerospace plastics market faces challenges due to the high cost of specialized materials and the lengthy approval process for aerospace use. Developing flame-retardant plastics that meet fire, smoke, and toxicity (FST) standards while maintaining lightweight and mechanical strength is expensive and time-consuming. Additionally, aerospace materials must undergo extensive testing and certification from regulatory bodies, which increases costs and delays time-to-market.

Smaller suppliers may struggle to meet these complex standards, leading to a limited pool of qualified vendors. These high entry barriers reduce competition and innovation speed. For aircraft manufacturers, the increased cost of compliant flame retardant plastics can also affect overall production budgets and procurement strategies.

Opportunities in the Flame Retardants for Aerospace Plastics Market

Growing Adoption of Non-Halogenated and Eco-Friendly Solutions

A major opportunity in the flame retardants for aerospace plastics market lies in the development and growing demand for non-halogenated, eco-friendly flame retardant solutions. As global regulations become stricter and environmental awareness increases, aerospace manufacturers are actively seeking safer alternatives that do not compromise performance.

Non-halogenated flame retardants, such as those based on phosphorus or nitrogen, produce less smoke and toxic gas, making them attractive for use in enclosed aircraft environments. This shift opens up innovation potential for chemical companies and compounders to develop sustainable, high-performance materials. Companies that invest in green technologies and can meet both safety and environmental standards are likely to gain a competitive edge. The trend also supports long-term regulatory compliance and market acceptance.

Expanding Aircraft Production and Modernization Projects

Another key opportunity is the rapid expansion of global aircraft fleets and modernization of aging aircraft, particularly in emerging markets. As air travel increases in regions like Asia-Pacific, the Middle East, and Latin America, the demand for new, efficient, and safe aircraft is rising. These new aircraft rely heavily on advanced plastic composites to reduce weight and improve fuel efficiency, all while maintaining high fire safety standards.

Additionally, older planes are being retrofitted with upgraded interiors and systems that use flame-retardant plastics. This creates strong, ongoing demand for certified flame retardant materials. Aerospace OEMs and suppliers that can meet this rising need with innovative and compliant solutions will benefit from this wave of investment in both new builds and refurbishments.

Trends in the Flame Retardants for Aerospace Plastics Market

Emergence of Nanotechnology-Enhanced Flame Retardants

A recent trend gaining momentum in the flame retardants for aerospace plastics market is the use of nanotechnology to improve fire-resistant properties. Nanoparticles such as nanoclays, carbon nanotubes, and metal oxides are being added to plastic composites to enhance thermal stability and reduce flame spread. These nano-additives work efficiently at low concentrations, which helps maintain the lightweight characteristics of aerospace materials.

They also reduce smoke density and toxic gas emissions, making them ideal for aircraft interiors. Manufacturers are increasingly combining nanomaterials with traditional flame retardants to create multifunctional systems. This approach allows for improved fire protection without compromising mechanical strength or processability. As research advances, nanotechnology is expected to play a larger role in aerospace material design.

Shift Toward Halogen-Free and Eco-Friendly Chemistry

Another major trend in the market is the growing shift from halogen-based flame retardants to halogen-free alternatives. Halogenated compounds, once widely used, are being phased out due to concerns over their environmental persistence and toxic smoke emissions. Aerospace manufacturers are now favoring phosphorus-based, nitrogen-based, and mineral-based flame retardants that offer safer, more sustainable solutions.

These alternatives meet strict fire safety standards while reducing the environmental footprint of aircraft materials. Halogen-free options also support circular economy goals by improving the recyclability of plastic components. This shift is driven by both regulatory pressures and customer demand for greener products. The trend is pushing companies to innovate while staying compliant with evolving global safety and environmental norms.

Impact of Artificial Intelligence in Flame Retardants for Aerospace Plastics Market

Artificial Intelligence (AI) is transforming the flame retardants for aerospace plastics market by accelerating material innovation and improving manufacturing efficiency. Through machine learning and data analysis, AI can rapidly evaluate large chemical datasets to identify new flame-retardant compounds with optimal fire resistance, low toxicity, and environmental safety. This shortens development timelines and enhances the ability to meet stringent aerospace fire, smoke, and toxicity (FST) standards. AI-powered modeling also supports virtual testing of materials, reducing the need for repeated physical trials and speeding up certification processes.

In production, AI enhances quality control by monitoring key parameters such as temperature, mixing ratios, and processing conditions in real time, ensuring consistent performance of flame-retardant plastics. Predictive maintenance systems further reduce operational downtime, which is critical in high-precision aerospace manufacturing. AI tools also assist in navigating regulatory landscapes by evaluating chemical compliance and environmental impact. Together, these advancements enable safer, more efficient, and sustainable flame-retardant solutions across the aerospace industry.

Research Scope and Analysis

By Product Analysis

Aluminum trihydrate, leading in 2025 with a projected market share of 38.7%, plays a major role in driving the growth of flame retardants for aerospace plastics. Known for its non-toxic, halogen-free properties, aluminum trihydrate is widely used in interior panels, insulation, and plastic components due to its ability to release water vapor when exposed to heat, which cools surfaces and suppresses flames.

Its cost-effectiveness, low smoke emission, and environmental safety make it a preferred choice in modern aircraft design. The material also improves mechanical strength when added to polymers, which is vital in aerospace applications. As regulatory bodies push for eco-friendly fire safety solutions, manufacturers are increasingly turning to aluminum trihydrate-based formulations. With the ongoing demand for lightweight and fire-safe plastic parts in aviation, this product is expected to maintain strong market traction throughout the forecast period and play a key role in shaping next-generation aerospace materials.

Magnesium hydroxide, having significant growth over the forecast period, is gaining popularity as a safer and environmentally friendly flame retardant in aerospace plastic applications. Unlike halogenated options, it produces minimal smoke and no harmful gases during combustion, making it ideal for aircraft interiors and sensitive cabin areas. When exposed to high heat, magnesium hydroxide decomposes and releases water, which helps in cooling the material surface and delaying fire spread.

It also enhances thermal stability and is compatible with various polymer systems used in aerospace. With increasing regulatory pressure to replace toxic flame retardants and a growing focus on passenger safety, the demand for magnesium hydroxide is steadily rising. Its multifunctional properties and low environmental impact are encouraging its adoption in modern aircraft manufacturing. As the aerospace industry continues shifting toward safer, lightweight materials, magnesium hydroxide is set to become an essential component in advanced flame retardant systems.

By Polymer Analysis

Carbon fiber-reinforced polymer, expected to lead the market in 2025 with a 37.2% market share, is playing a major role in boosting the flame retardants for aerospace plastics market. Its lightweight structure, combined with exceptional strength and heat resistance, makes it ideal for various aircraft components such as fuselage sections, interior panels, and brackets. When enhanced with flame retardant additives, this composite meets the strict fire, smoke, and toxicity standards required in the aerospace industry.

The growing need for fuel efficiency and performance is pushing manufacturers to use more carbon fiber composites in aircraft designs. Additionally, its ability to maintain integrity under high temperatures while offering design flexibility supports its widespread adoption. With the global push for safer and more efficient materials, carbon fiber reinforced polymer is expected to stay at the forefront of aerospace plastic innovation and fire protection.

Polycarbonate, having significant growth over the forecast period, is becoming an important polymer in the development of flame-retardant aerospace plastics. Known for its impact resistance, transparency, and thermal stability, polycarbonate is widely used in cabin windows, light covers, and other interior fittings. When treated with flame retardants, it meets critical safety standards without losing its physical strength.

Its lightweight nature also supports the aviation industry's focus on reducing aircraft weight to improve fuel efficiency. As safety regulations tighten and the demand for cost-effective, durable materials rises, more aerospace manufacturers are turning to flame-retardant polycarbonate solutions. The material’s versatility and ease of processing make it suitable for both commercial and defense aviation sectors. Its growing role in replacing heavier materials adds to its appeal, making polycarbonate a strong contributor to the future of aerospace plastics with built-in fire protection.

The Flame Retardants for Aerospace Plastics Market Report is segmented on the basis of the following:

By Product

- Aluminum Trihydrate

- Antimony Oxide

- Phosphorus Compounds

- Boron Compounds

- Magnesium Hydroxide

- Others

By Polymer

- Carbon Fiber Reinforced Polymer (CFRP)

- Polycarbonate (PC)

- Glass Reinforced Plastic (GRP)

- Thermoset Polyimides

- Polyoxymethylene (POM)

- Acrylonitrile Butadiene Styrene (ABS)

- Others

Regional Analysis

Leading Region in the Flame Retardants for Aerospace Plastics Market

Europe, leading in 2025 with a share of 47.5%, plays a major role in the growth of the flame retardants for aerospace plastics market. The region’s strong presence in commercial aircraft manufacturing, supported by countries like France, Germany, and the UK, drives consistent demand for advanced fire-resistant plastic materials. Flame retardants are widely used in cabin interiors, wiring systems, and lightweight structural parts to meet strict safety standards.

European regulations, especially around fire, smoke, and toxicity levels, are among the strictest in the world, pushing companies to develop cleaner, non-halogenated, and more efficient flame retardant solutions. The aerospace sector in Europe continues to invest in sustainable technologies, with a growing focus on green and recyclable materials. Alongside new aircraft production, ongoing retrofitting and refurbishment programs also increase the need for high-performance flame-retardant plastics. With a strong mix of regulation, innovation, and demand, Europe remains a vital and growing market for flame retardants used in aerospace plastic applications during 2025.

Fastest Growing Region in the Flame Retardants for Aerospace Plastics Market

Asia Pacific is showing significant growth over the forecast period in the flame retardants for aerospace plastics market, driven by rising aircraft production, expanding airline fleets, and increasing investments in aviation infrastructure. Countries like China, India, and Japan are boosting demand for flame-retardant plastic materials used in aircraft interiors, wiring systems, and lightweight structural parts.

The region’s growing focus on passenger safety and regulatory compliance is encouraging the adoption of advanced, halogen-free flame retardant compounds. Along with commercial aviation, the defense and cargo sectors are also contributing to this demand. With strong manufacturing capabilities and growing domestic air travel, Asia Pacific is estimated to become a key growth engine for the market.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The competitive landscape of the flame retardants for aerospace plastics market is shaped by strong research, strict regulations, and the constant need for safer, lighter, and more durable materials. Many companies focus on developing innovative, non-toxic, and environmentally friendly flame retardant solutions to meet evolving fire safety standards. The market includes chemical producers, plastic compounders, and aerospace material suppliers working together to create advanced products.

Competition is high as players aim to offer materials that not only meet safety rules but also enhance performance and reduce weight. Partnerships, certifications, and testing capabilities often decide market leadership. As sustainability becomes more important, companies that invest in green technologies and comply with international aviation safety standards gain a competitive edge.

Some of the prominent players in the global Flame Retardants for Aerospace Plastics are:

- BASF SE

- Clariant AG

- LANXESS AG

- Albemarle Corporation

- ICL Group

- DuPont

- SABIC

- Huber Engineered Materials

- Italmatch Chemicals S.p.A.

- RTP Company

- DIC Corporation

- Dow Inc.

- Evonik Industries AG

- Israel Chemicals Ltd.

- Nabaltec AG

- Thor Group Ltd.

- Chemtura Corporation

- DSM Engineering Materials

- Shin-Etsu Chemical Co., Ltd.

- Kaneka Corporation

- Other Key Players

Recent Developments

- In March 2025, Endeavor 3D has added HP PA 12 Flame Retardant (FR) to its polymer additive manufacturing services, becoming one of the first U.S. HP Digital Manufacturing Partners to offer this High Reusability material. Validated for use with HP’s Multi Jet Fusion (MJF) technology, the material enables cost-effective production of flame-retardant components.

- In March 2025, Xeriant, Inc., focused on developing disruptive technologies in advanced materials and aerospace, has reached a key milestone with the completion of its eco-friendly NEXBOARD™ nanocomposite construction panel. In-house testing confirmed that NEXBOARD’s flame-retardant system met the stringent 15-minute fire and thermal resistance requirement, a crucial achievement for securing top-level certification. This success marks a major step toward finalizing the panel’s composition, paving the way for its upcoming production and commercialization as a game-changing solution in sustainable building materials.

- In October 2024, Avient Corporation showcased its latest sustainable and advanced material solutions for the plastics industry. Among the highlights are two new product launches: globally manufactured thermoplastic elastomers (TPEs) featuring up to 60% post-consumer recycled (PCR) content, and metallic pre-colored sulfone compound colorants available in gold, bronze, and silver finishes. These innovations reflect Avient’s commitment to sustainability and high-performance plastic solutions.

- In October 2024, The US Department of Commerce has issued a preliminary affirmative decision to impose countervailing duties on alkyl phosphate esters imported from at least three Chinese companies. These chemicals, mainly used as flame retardants in rigid and flexible polyurethane foams like TCPP, TDCP, and TEP, will now face higher duties. Preliminary rates include 96.83% for Anhui RunYue Technology, 35.47% for Zhejiang Wansheng, and 546.13% for Zhejiang Wanda Tools Group, while others face 50.15%. Previously, a general 25% duty was applied. Antidumping duties are still under review.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 38.4 Mn |

| Forecast Value (2034) |

USD 76.8 Mn |

| CAGR (2025–2034) |

8.0% |

| Historical Data |

2019 – 2024 |

| The US Market Size (2025) |

USD 7.8 Mn |

| Forecast Data |

2025 – 2033 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors, etc. |

| Segments Covered |

By Product (Aluminum Trihydrate, Antimony Oxide, Phosphorus Compounds, Boron Compounds, Magnesium Hydroxide, and Others), By Polymer (Carbon Fiber Reinforced Polymer (CFRP), Polycarbonate (PC), Glass Reinforced Plastic (GRP), Thermoset Polyimides, Polyoxymethylene (POM), Acrylonitrile Butadiene Styrene (ABS), and Others) |

| Regional Coverage |

North America – US, Canada;

Europe – Germany, UK, France, Russia, Spain, Italy, Benelux, Nordic, Rest of Europe;

Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC;

Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America;

Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, Rest of MEA

|

| Prominent Players |

BASF SE, Clariant AG, LANXESS AG, Albemarle Corporation, ICL Group, DuPont, SABIC, Huber Engineered Materials, Italmatch Chemicals S.p.A., RTP Company, DIC Corporation, Dow Inc., Evonik Industries AG, Israel Chemicals Ltd., Nabaltec AG, Thor Group Ltd., Chemtura Corporation, DSM Engineering Materials, Shin-Etsu Chemical Co., Ltd., Kaneka Corporation, and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user),

Multi-User License (Up to 5 Users), and

Corporate Use License (Unlimited User) along with free report customization equivalent to

0 analyst working days, 3 analysts working days, and 5 analysts working days respectively.

|

Frequently Asked Questions

The Global Flame Retardants for Aerospace Plastics Market size is expected to reach a value of USD 38.4 million in 2025 and is expected to reach USD 76.8 million by the end of 2034.

Europe is expected to have the largest market share in the Global Flame Retardants for Aerospace Plastics Market, with a share of about 47.5% in 2025.

The Flame Retardants for Aerospace Plastics Market in the US is expected to reach USD 7.8 million in 2025.

Some of the major key players in the Global Flame Retardants for Aerospace Plastics Market are BASF SE, Clariant AG, LANXESS AG, , and others

The market is growing at a CAGR of 8.0 percent over the forecasted period.