Market Overview

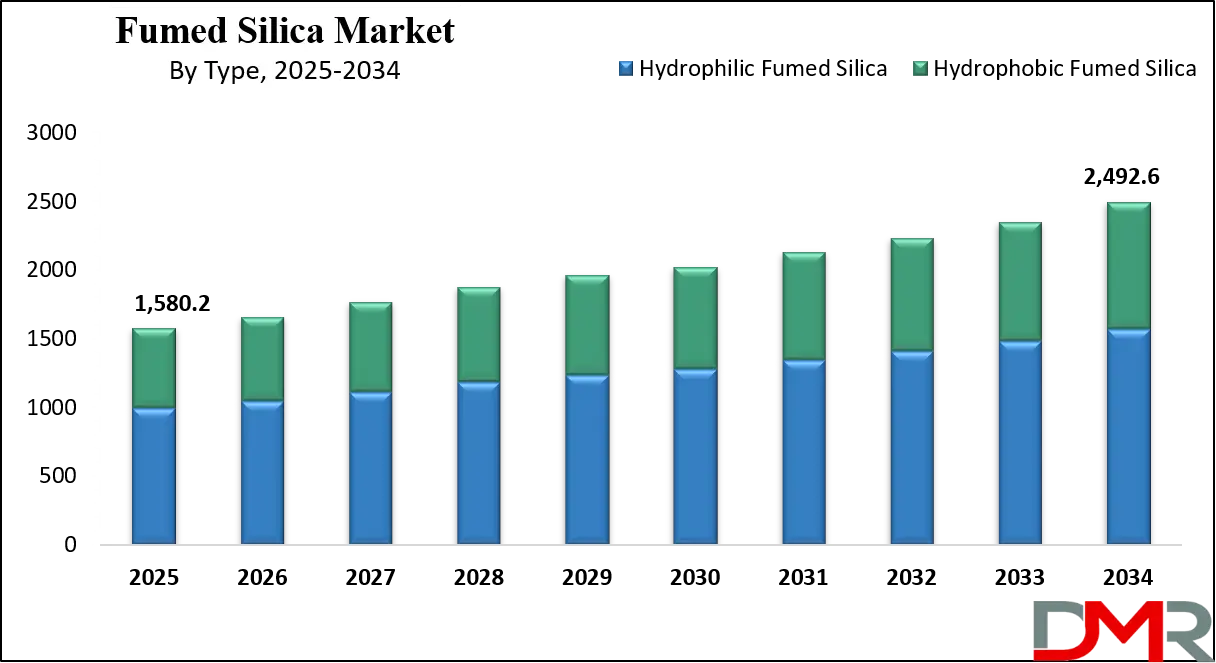

The Global Fumed Silica Market size is expected to be valued at USD 1,580.2 million in 2025, and it is further anticipated to reach a market value of USD 2,492.6 million by 2034 at a CAGR of 5.2%.

Fumed silica experiences continuous market growth because industries including paints and coatings and automotive manufacturing, together with pharmaceuticals and personal care, support its expansion. Fumed silica or pyrogenic silica stands out in manufacturing because of its tiny dimensions and huge surface area, along with its great thixotropic properties that boost product final output attributes.

Organizations make extensive use of fumed silica silicon for developing new electronic devices while creating better energy storage technologies. The semiconductor encapsulation process and circuit board insulation method, and lithium-ion battery electrolyte system enhancement with fumed silica, enhance device stability and operation performance. The value of fumed silica continues increasing within cosmetics and skincare markets because it enhances product texture and shelf stability and improves product suspension. The market demands high-performance along with clean-label personal care products, so these adoption trends match consumer preferences.

New business opportunities are developing in pharmaceutical excipients because fumed silica helps powders flow better and produces uniform tablets, and manages controlled drug delivery systems. Fumed silica enables next-generation solar panel development along with energy-efficient materials for the renewable energy sector, which creates a profitable business frontier. The market develops bio-based fumed silica while improving production processes to achieve lower emission levels through sustainability-focused innovation.

Although the market has its share of significant obstacles to overcome. The production process of fumed silica requires energy-consuming flame hydrolysis of silicon tetrachloride, so companies pay higher operating costs. The implementation of environmental rules about emissions, together with workplace security standards, creates increased compliance requirements. The operating risks for the industry become worse due to the volatile costs of silicon-based raw materials.

The market for fumed silica products continues its positive growth trajectory because scientists innovate material technologies. The multifunctional nature of fumed silica will keep it as a fundamental component for advanced industrial applications worldwide because industries focus on product efficiency while pursuing smaller designs and sustainable initiatives.

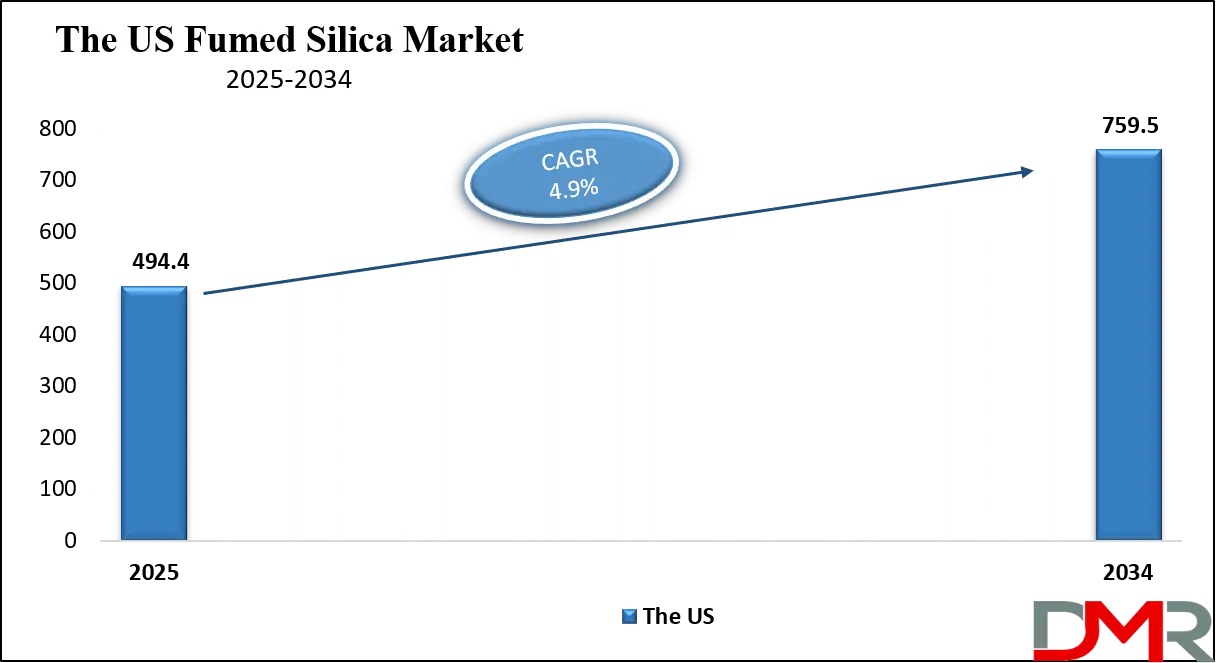

The US Fumed Silica Market

The US Food Preservatives Market is estimated to be valued at USD 494.4 million in 2025, and projections suggest it will grow to USD 759.5 million by 2034, at a steady CAGR of 4.9%.

Fumed silica exhibits significant market demand in the United States because of its powerful support from technological production and robust end-user sectors. Fumed silica finds extensive application across high-value industries consisting of pharmaceuticals and construction alongside electronics and automotive sectors because of its role in sustaining product quality standards and protecting user safety and regulatory requirements.

The U.S. Census Bureau, together with the U.S. Department of Commerce, indicates that more than 700,000 construction enterprises operate within the United States while the country builds up its infrastructure through bipartisan investments. Performance-enhancing additives receive higher demand from the construction industry because investments require fumed silica in concrete admixtures and sealants, and insulation materials. Silica has received General Recognized As Safe (GRAS) status approval from the U.S. Food and Drug Administration, thus making it suitable for usage in pharmaceutical-grade and food-grade formulations.

The U.S. also benefits from a robust R&D environment, with institutions such as the National Institutes of Health and the National Science Foundation supporting innovation in drug delivery and advanced materials. The electronics sector of Silicon Valley utilizes fumed silica in multiple high-tech packaging and thermal management systems.

The EPA along with OSHA regulates the U.S. market through environmental compliance laws and labor costs represent significant market limitations. Sustainable production techniques that use plasma-based silica synthesis together with circular manufacturing practices deliver solutions to limit sustainability problems. The mix of industries across the nation and strict quality control standards create positive conditions for fumed silica manufacturers and suppliers to grow in the future.

The European Fumed Silica Market

The European Food Preservatives Market size is estimated to be valued at USD 278.12 million in 2025, and projections suggest it will grow to USD 402.75 million by 2034, at a steady CAGR of 4.2%.

Fumed silica has a fully developed market position within Europe, thanks to the advanced regulatory structure, along with strong environmental awareness and high technological capabilities. Fumed silica serves as a high-performance additive throughout various industrial sectors such as automotive engineering, personal care, life sciences, and green construction within the European region.

The European Commission and Eurostat reveal that Europe tops the world regarding environmentally-friendly construction materials while maintaining the strictest chemical regulations under REACH standards. Manufacturers now have the opportunity to innovate advanced low-carbon production methods through these targets, which match the EU Green Deal objectives. The widespread implementation of fumed silica occurs in green cement production and bio-based coating technologies, and hybrid adhesive products for meeting EU environmental certification requirements.

The use of fumed silica materials at high levels among German and Italian, and French industry actors originates from their respective strong automotive production sector alongside pharmaceutical manufacturing facilities. German national and educational research organizations within the Fraunhofer Institute and other academic domains work on developing future fumed silica applications for nanotechnology and energy storage solutions. Personal care market demand demonstrates resilience through the marketing of natural beautifying products that incorporate fumed silica as a stabilizing agent.

The risk for this industry exists because of high energy expenses combined with the need for imported silicon raw materials. Increasing political tensions combined with material supply constraints from Eastern European and Chinese regions establish critical weaknesses in supply chain operations. The European commitment toward smart materials development and circular manufacturing ensures fumed silica will maintain a positive outlook for future consumer and industrial markets.

The Japan Fumed Silica Market

It is expected that the Japan Food Preservatives Market will be valued at USD 94.8 million in 2025 and is likely to grow to USD 142.12 million by 2034, registering a CAGR of 4.6%.

The market for fumed silica in Japan operates at an innovative technological level while maintaining ongoing sector demand from electronics and personal care industries, along with automotive and high-end construction sectors. Due to its strong focus on precision manufacturing techniques and material research, Japan serves as a leading force among Asian specialty chemicals market players.

The Ministry of Land, Infrastructure, Transport and Tourism (MLIT) remains dedicated to supporting infrastructure projects encompassing earthquake resilience and smart cities, which boosts the market demand for advanced materials such as silica-reinforced concrete and sealants. METI (Ministry of Economy, Trade and Industry) states that Japan maintains its worldwide leadership position in semiconductor manufacturing and passive components that depend on silica-based encapsulation and insulation technologies.

The automotive industry applies fumed silica to develop tires that perform better and reduce rolling resistance, along with achieving improved fuel efficiency. Japanese government initiatives regarding electric mobility and hydrogen fuel infrastructure development will create additional opportunities for fumed silica utilization in battery technology and membrane systems. Japanese cosmetic brands apply fumed silica as an ingredient to achieve better texture and collect oil across their product lines since they focus on high-quality innovations in their formulations.

A restricted workforce, together with increasing energy expenses, both affect the timeframe of construction projects and manufacturing profit margins. Manufacturers in Japan face significant supply chain risk because they depend heavily on importing raw materials. The fumed silica market maintains optimism because Japan strengthens product innovation through its research-oriented culture despite facing market challenges.

Global Fumed Silica Market: Key Takeaways

- Global Market Size Insights: The Global Fumed Silica Market size is estimated to have a value of USD 1,580.2 million in 2025 and is expected to reach USD 2,492.6 million by the end of 2034.

- The US Market Size Insights: The US Fumed Silica Market is projected to be valued at USD 494.4 million in 2025. It is expected to witness subsequent growth in the upcoming period as it holds USD 759.5 million in 2034 at a CAGR of 4.9%.

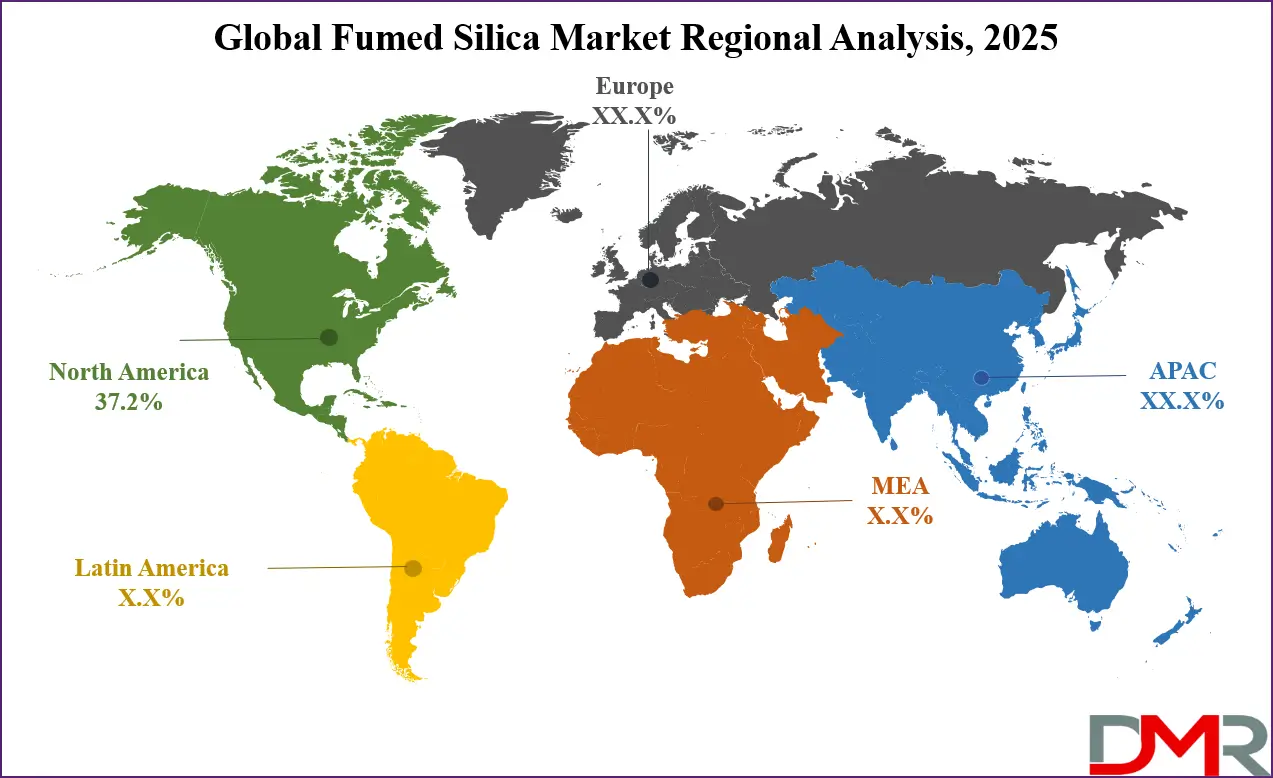

- Regional Analysis: North America is expected to have the largest market share in the Global Fumed Silica Market, with a share of about 37.2% in 2025.

- Key Players: Some of the major key players in the Global Fumed Silica Market are Evonik, Cabot, Wacker Chemie, Tokuyama, OCI, Kemitura, Dongyue, Gelest, Xingfa, Xunyu, Nouryon, Shin-Etsu, Bluestar, Polysil, and many others.

- Global Growth Rate Insights: The market is growing at a CAGR of 5.2 percent over the forecasted period of 2025.

Global Fumed Silica Market: Use Cases

- Paints and Coatings: Industrial applications of fumed silica include paint and coating functions that use it to stabilize viscosity levels and stop pigments from settling and to create smooth surfaces. Architectural and automotive paint products receive benefits from its presence because it enables even application layers and improved scratch resistance, and extended shelf life.

- Adhesives and Sealants: The material performs dual roles as a viscosity controller and sag-preventive agent in aerospace and marine, and construction sector adhesives and sealants applications to enhance their bonding capabilities with easy application characteristics due to shear-thinning behavior.

- Pharmaceuticals: The flowability of pharmaceutical powders improves due to fumed silica, which also prevents product caking and enables better distribution of medicinal components. The substance contributes essential functions for achieving proper tablet and capsule structure in nutraceuticals, along with prescription pharmaceuticals.

- Personal Care Products: Fumed silica appears in personal care offerings to serve three vital cosmetic functions, including skin mattification and spreading enhancement, and ingredient maintenance when mixed into lotions and sunscreens, and foundations.

- Electronics: The electronics industry uses fumed silica as a thermal insulation agent to improve the properties of potting compounds and thermal interface materials, and silicone encapsulants. Fumed silica lengthens product life through its ability to boost heat tolerance, along with its ability to shield from moisture and add mechanical stability for microelectronic devices.

Global Fumed Silica Market: Stats & Facts

United States Census Bureau

- In 2022, the U.S. construction industry contributed 4.3% to the nation’s GDP, with a market size of around USD 1.79 trillion. Construction spending reached USD 1,463.5 billion during the first nine months of 2023, a 4.6% increase from 2022.

Occupational Safety and Health Administration (OSHA)

- OSHA’s permissible exposure limit (PEL) for fumed silica is set at 20 million particles per cubic foot (mppcf), equating to 0.8 mg/m³ for pure fumed silica. This standard ensures worker safety during silica handling and exposure.

National Bureau of Statistics of China

- In 2022, China’s construction output value reached USD 4.64 trillion, a 6% increase from USD 4.36 trillion in 2021, reflecting the growing demand for advanced construction materials, including fumed silica, across various sectors.

U.S. Geological Survey (USGS)

- China produced approximately 7,400 thousand metric tons of silicon in 2024, representing 80% of global silicon production. This significant output underscores China’s dominance in silicon production, a key material in the manufacturing of fumed silica.

International Organization of Motor Vehicle Manufacturers (OICA)

- Global vehicle production reached 85.02 million units in 2022, marking a 6% increase from 2021. The Asia-Pacific region contributed 50.02 million units in 2022, accounting for over 58% of global automotive manufacturing, which drives demand for silica-based components.

India Brand Equity Foundation (IBEF)

- India’s electronics manufacturing aims to reach USD 300 billion by 2026, with domestic consumer electronics demand projected to hit USD 21.18 billion by 2025. This growing sector increases the demand for high-quality materials like fumed silica in electronics.

- India’s passenger vehicle production in April 2024 reached 2.36 million units, showing a strong manufacturing base for automotive components where fumed silica plays a crucial role in enhancing material strength and performance.

United Nations Comtrade

- In 2023, China’s plastic exports were valued at USD 131.45 billion. The country’s strong position in the plastics industry underlines the need for additives such as fumed silica, used to enhance the properties of various plastic products.

World Paint & Coatings Industry Association

- The global paint and coatings market reached USD 179.7 billion in 2022, with fumed silica playing a critical role in improving viscosity, texture, and stability, making it indispensable in the production of high-performance coatings and paints.

American Coatings Association

- In 2022, the U.S. paint production totaled 1.36 billion gallons, highlighting a strong demand for coatings. Fumed silica plays a vital role in improving the performance, consistency, and durability of paints used across architectural and industrial applications.

Semiconductor Industry Association

- China remains the largest market for semiconductors globally, with a significant share of production and consumption. Fumed silica is integral to the production of insulating materials used in semiconductor devices, making it critical for the electronics industry.

Food and Drug Administration (FDA)

- The FDA permits fumed silica to be used as a food additive, restricting its presence to a maximum of 2% by weight in food products. This regulation ensures its safe use in the food industry while enhancing product flow and texture.

Safe Work Australia

- Safe Work Australia has revised exposure standards for crystalline silica, including fumed silica, to safeguard workers in industries where silica dust is present. These standards are essential for reducing health risks associated with prolonged exposure to fumed silica.

Construction Association (U.S.)

- As of 2023, there were over 919,000 construction establishments in the U.S., contributing nearly USD 2.1 trillion annually to the economy. The growing infrastructure development demands high-performance materials like fumed silica for enhanced building materials.

Global Fumed Silica Market: Market Dynamic

Driving Factors in the Global Fumed Silica Market

Rising Demand in Electronics and Pharmaceuticals

The electronics and pharmaceutical industries drive the fumed silica market expansion through their growing demand. The market growth of fumed silica continues to expand because it serves as an essential agent in electronics and pharmaceutical applications. Semiconductor encapsulation requires fumed silica in electronics for insulation purposes while improving the performance of electronic components. The market demand for small devices and high-performance materials urges producers to utilize increasing amounts of fumed silica.

Pharmaceutical drug formulations require fumed silica as a crucial component because the material enhances drug stability while improving its availability to patients. Its ability to boost drug delivery methods alongside dosage form standardization has motivated pharmaceutical production facilities to adopt fumed silica more frequently. New research activity and developmental advancements within these industries maintain ongoing growth, which steers the demand trend for fumed silica.

Expansion in the Construction and Automotive Industries

Fumed silica market growth depends heavily on the construction industry, together with the automotive sector. Construction developers rely on fumed silica to improve concrete properties and paint resilience, as well as coating durability for better performance outcomes. Global construction expansion, especially in developing economies, causes rising demand for high-performance materials that fumed silica represents.

The automotive sector uses fumed silica during rubber component manufacturing to create tires as well as other parts that impact driving efficiency and safety. The advancement towards building fuel-efficient lightweight vehicles significantly boosted the market need for fumed silica. Fumed silica market growth is increasingly expanding due to spatial development, technological developments, and industrial advancements.

Restraints in the Global Fumed Silica Market

High Production Costs and Raw Material Price Volatility

Fumed silica market presents a main constraint because its production involves energy-intensive manufacturing, which leads to expensive manufacturing operations. Manufacturing fumed silica demands large amounts of energy, thus resulting in elevated operational costs. Raw material price variations of silicon and chlorine substances increase production costs, which create additional difficulties for fumed silica markets. The market costs and profit levels of fumed silica production experience significant changes because of price fluctuations.

Manufacturers must balance their operational expenses with product quality standards because either burden hinders market growth, particularly in price-sensitive zones. The fumed silica market faces major numerical difficulties because of its high production expenses and erratic raw material price volatility.

Stringent Environmental and Safety Regulations

The fumed silica market operates within strict environmental and safety regulations that affect its expansion potential. Multiple regulatory authorities created strict production codes as well as rules for handling and using fumed silica to safeguard workers and protect the environment. The fulfillment of regulatory standards demands substantial investments in protective measures, along with waste system management and pollution control technology, which raises operational expenses.

Non-compliance results in both legal penalties combined with negative consequences for corporate reputation. Manufacturers face regulatory obstacles in markets with strict environmental standards, thus, this creates barriers for both new market players and existing production facilities to grow. The fumed silica market faces substantial growth restrictions because of its need to handle extensive regulatory requirements.

Opportunities in the Global Fumed Silica Market

Emerging Applications in Renewable Energy

The renewable energy industry delivers numerous growth prospects for the fumed silica market sector. The production of high-performance batteries together with photovoltaic panels incorporates fumed silica to enhance renewable energy system efficiency and operational duration. The unique properties of fumed silica improve both battery separators and energy storage device stability in performance applications.

Fumed silica material usage is anticipated to expand because global markets transition to sustainable energy solutions. The application of fumed silica in renewable energy technologies supports environmental objectives and provides new business opportunities for market expansion. Organizations that enter this field will have the potential to earn profits from the rising need for sustainable power solutions.

Development of Eco-Friendly and Sustainable Products

The creation of novel, sustainable, and eco-friendly fumed silica products represents an attractive strategy to increase market expansion. Various firms dedicate their efforts toward developing recyclable and bio-based fumed silica solutions to fulfill growing market needs for sustainable products. The market drives this evolution because governments enforce strict environmental standards, and more people become aware of sustainable issues.

Sustainable methods within fumed silica manufacturing help businesses meet regulatory needs and boost their market position while establishing a strong environmental brand reputation. The implementation of sustainable product development allows companies to expand their market reach by serving customers who hold environmental concerns. The market expansion of fumed silica depends heavily on sustainable market initiatives.

Trends in the Global Fumed Silica Market

Sustainable and Eco-Friendly Production

Across the world, the fumed silica manufacturing industry now remains focused on adopting sustainable production practices that minimize environmental impact. The fumed silica manufacturing industry moves toward green chemistry through low-carbon production approaches to minimize environmental effects. The market shows this development because environmental standards have become stricter, and consumers want products from sustainable sources.

The drive for global sustainability prompts companies to finance the development of recyclable fumed silica solutions through research efforts. Companies that adopt sustainable procedures fulfill regulatory needs while gaining market stability by connecting with environmentally oriented customers. The fumed silica market can predict future growth because sustainability stands as the main focus for this industry.

Integration in Advanced Technologies

The technological advancement of electronics and energy storage functions increasingly depends on fumed silica incorporation. The fumed silica substance functions as an essential element for semiconductor encapsulation, along with battery manufacturing, which boosts electronic device performance and reliability. The distinctive qualities of the material, including extensive surface area and thixotropic properties, establish it as a required substance for these applications.

Fumed silica proves essential for high-performance battery production, thanks to its ability to improve energy density and stability, because electric vehicles and renewable energy technology have been increasing. Modern industry and technology developments benefit from fumed silica integration within advanced technologies, which enables ongoing innovation while expanding its application limits to become a fundamental material.

Global Fumed Silica Market: Research Scope and Analysis

By Type Analysis

Hydrophilic fumed silica is projected to control the global market because of its broad usability and good dispersion ability, along with an affordable price. Workers generate hydrophilic fumed silica by applying silicon tetrachloride through flame hydrolysis into a hydrogen-oxygen flame, leaving this type of fumed silica both pure and high in surface area and containing silanol groups on its surface to promote hydrogen bonding. Its excellent characteristics suit numerous industrial uses which depend on rheological control and stability improvement.

Companies operating in the paint and coating industry, along with entities involved in the production of adhesive sealants and personal care products, commonly select hydrophilic fumed silica for its applications in enhancing product texture maintenance and controlling flow dynamics. The additive feature of thixotropy suits hydrophilic silica perfectly as an ideal rheological agent, particularly in solvent-based applications. The hydrophilic behavior of fumed silica lets it serve a wider range of applications than hydrophobic versions because hydrophobic materials need chemical treatment to function properly only within non-polar systems.

Cost is another key factor. The production costs of hydrophilic fumed silica remain lower compared to hydrophobic grades because hydrophobic modification after production is unnecessary. These characteristics make the product more accessible to cost-sensitive sectors, particularly when dealing with manufacturers. Surface treatment methods and modern dispersion techniques help advance hydrophilic grade performance to make them more applicable in recent formulations.

The combination of straightforward handling characteristics and low environmental impact makes hydrophilic fumed silica secure its leading position in industrial markets under increasing standards for environmentally friendly and efficient additives. These combined features of performance quality, combined with economic advantages, ensure that hydrophilic fumed silica will maintain its market leadership over other types of silica.

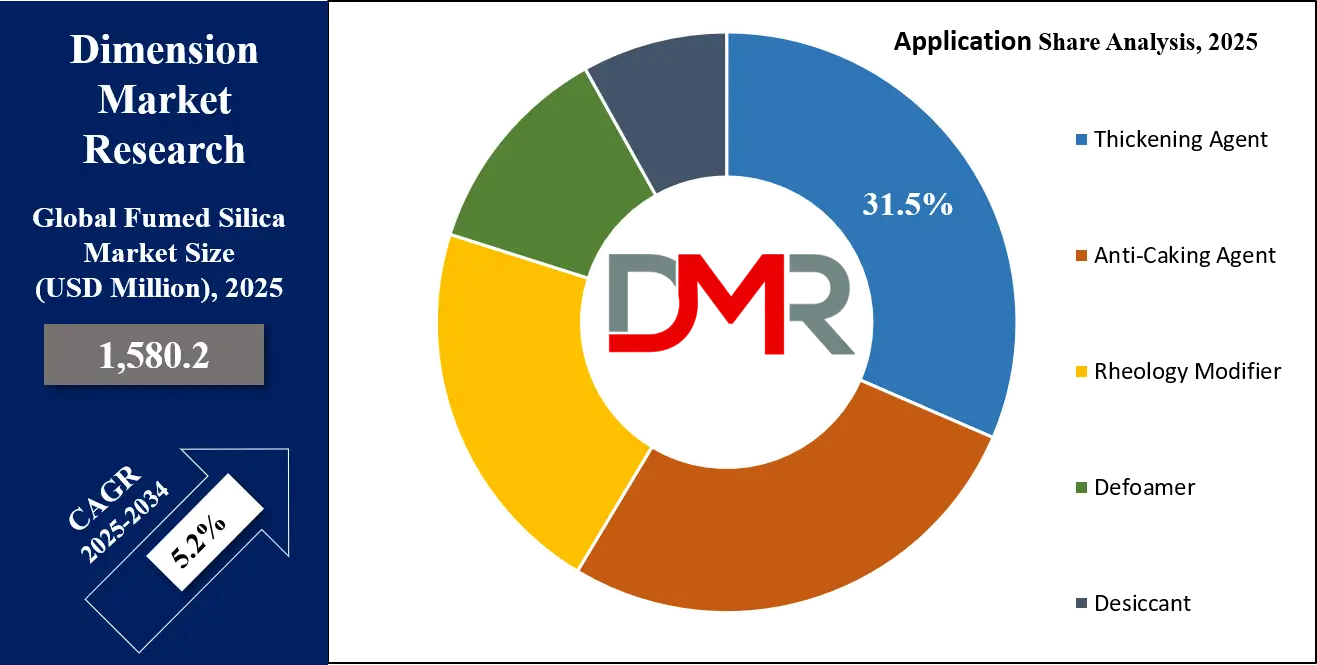

By Application Analysis

Thickening is projected to be the leading application of fumed silica, accounting for a major share by the end of 2025. The thickening application of hydrophilic fumed silica uses the highest amount worldwide because this material efficiently modifies viscosity and gives formulations structural stability. Fumed silica functions through its three-dimensional network creation with liquid media to build viscosity while preserving other chemical properties unchanged. This material works well as a thickening agent due to its suitability for many industries.

Fumed silica functions as a thickening and emulsion stabilizing agent in creams, lotions, and gels while improving their final product texture for the personal care industry. No toxicity, combined with its inert nature, makes this material perfect for direct contact with skin. The paints and coatings sector uses fumed silica to prevent settling and offer resistance to sag, thus achieving consistent application and extended product shelf life. Fumed silica functions as both a sedimentation stabilizer of pigments and fillers and a flow controller for targeted applications.

Fumed silica serves the adhesives and sealants sector by enhancing adhesion through the maintenance of uniform and non-runny thick liquid characteristics. The thickening characteristics of fumed silica help improve grease and lubricant performance at high temperatures.

Its high-performance thickening function strengthens its market position because it operates effectively within harsh environments of temperature and chemical resistance, and shear stress. Fumed silica leads the thickening agent market because industries need stability in their formulations, thus generating steady market expansion.

By End-Use Industry Analysis

The paints and coatings industry is anticipated to hold the largest share in the global fumed silica market by the end of 2025. The paints and coatings sector contains the largest part of the worldwide fumed silica market because fumed silica serves multiple functions to boost durability while maintaining product consistency and performance. Fumed silica serves as a rheology modifier, along with being an anti-settling agent and thickener within both water-based and solvent-based formulations that are commonly used in industry. Fumed silica possesses properties that enhance how coatings stay stable in storage while modifying their application dynamics and improving their visible appearance, resulting in superior market penetration.

This material stops color and additive particles from floating in architectural and industrial coatings, thus maintaining uniform distribution throughout the solution. When shear occurs, like brushing and spraying, fumed silica material flows as a paint does, but keeps its rest viscosity in place to prevent sagging on vertical surfaces for better finish quality. Such properties prove essential for decorative and protective coatings since they need both uniform composition and superior surface appearance.

The dominance of fumed silica has been strengthened by environmental regulatory standards. The market demands low-VOC and environmentally friendly coating systems, causing fumed silica to become a preferred additive because it allows high-performance formulations to meet regulatory standards while maintaining quality outcomes. The vital characteristics of scratch resistance and durable film structure make fumed silica a necessary component for automotive and industrial paintings, which prioritize durability.

Reliable and multifunctional additives such as fumed silica experience sustained market growth because of ongoing urbanization and global infrastructure advancement and high-performance coating requirements in emerging economies. Fumed silica serves the paints and coatings sector to the highest degree due to its adaptability and exceptional performance attributes, thus securing its leading position within this industry.

The Global Fumed Silica Market Report is segmented on the basis of the following:

By Type

- Hydrophilic Fumed Silica

- Hydrophobic Fumed Silica

By Application

- Thickening Agent

- Anti-Caking Agent

- Rheology Modifier

- Defoamer

- Desiccant

By End-Use Industry

- Paints & Coatings

- Adhesives & Sealants

- Personal Care & Cosmetics

- Pharmaceuticals

- Food & Beverages

- Silicone Rubber

- Agriculture

- Electronics

Global Fumed Silica Market: Regional Analysis

Region with the Highest Market Share in the Global Fumed Silica Market

North America is expected to dominate the global fumed silica market as it commands over 37.2% of the total revenue by the end of 2025. Fumed silica leads market dominance in North America because of its established industrial sector, combined with technological progress and wide industry sector applications. The regional economy drives many major industrial operators, including construction companies, along with automotive manufacturers and electronics firms, and pharmaceuticals that base their product success on fumed silica components. The United States stands out for its industrial strength and regulatory structure, which enables innovative development of high-purity additives through fumed silica advancement.

North America demands high-quality fumed silica because it offers extensive applications in coatings, adhesives, and personal care formulations, which need to meet safety and environmental specifications. Leading research institutions in combination with major R&D investments enable specialized silica grade development for semiconductor encapsulation, together with biomedical applications.

Strong distribution networks combined with well-developed infrastructure and the presence of multinational chemical producers make the region lead the market. The North American market for fumed silica retains momentum because lightweight, sustainable materials gain popularity, specifically through the automotive and aerospace industries.

Region with the Highest CAGR in the Global Fumed Silica Market

Industrial development combined with population growth and increases in middle-class numbers across Asia Pacific drives the regional fumed silica market to expand at its highest compound annual growth rate (CAGR) globally. Fumed silica finds its primary application in the developing sectors of China and India in conjunction with the advanced production of Japan and South Korea.

The biggest chemical manufacturing center in the world, which is China, is spending significant resources on building new facilities and developing advanced high-tech manufacturing that requires fumed silica materials for performance enhancement. The Indian pharmaceutical industry, together with its expanding cosmetics market, generates new opportunities for fumed silica applications because consumers need safer and better-performing formulations.

Labor cost efficiency, coupled with accessible raw materials, combined with industrial support from the government, makes Asia Pacific an optimal market for manufacturing and product consumption. Asia Pacific’s increasing emphasis on sustainable chemistry and green practices drives the development of eco-friendly fumed silica grades, which will support sustainable long-term industry growth. The fast market expansion within the region stems from its extensive scale as well as a broad range of industries and forceful industrial development.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Global Fumed Silica Market: Competitive Landscape

The global fumed silica market consists of multinational and regional business competitors who compete in terms of price and product quality while prioritizing innovation. Evonik Industries, along with Cabot Corporation and Wacker Chemie AG, and OCI Company Ltd, control the market space through their broad product ranges and international distribution chains, and continuous innovation investments. The firms pursue capacity expansion while improving production systems and exploring new application opportunities, especially within high-growth markets of personal care and energy storage, and electronics.

Through strategic deals of partnership and acquisition, companies build their market dominance. Partnerships between companies include working with local formulators and end-users to create localized solutions and meet performance requirements while adhering to regional regulations. The market evolution depends on modern surface treatment discoveries along with hybrid nanomaterial creation, which sets companies apart from their competitors.

Asia-based regional firms strengthen their positions in the market through both lower costs and enhanced technical abilities. Western companies dominate premium applications because they specialize in producing high-purity, specialized fumed silica.

The market has changed as companies need to demonstrate environmental sustainability while implementing circular economy practices along with strict adherence to Global regulations. Companies that achieve lower carbon emissions, together with green-based product lines, receive rising customer and regulatory support, which reforms market competition scenarios.

Some of the prominent players in the Global Fumed Silica Market are:

- Evonik Industries AG

- Cabot Corporation

- Wacker Chemie AG

- Tokuyama Corporation

- OCI Company Ltd.

- Kemitura A/S

- Dongyue Group Ltd.

- Gelest Inc.

- Hubei Xingfa Chemicals Group Co., Ltd.

- Henan Xunyu Chemical Co., Ltd.

- Nouryon

- Shin-Etsu Chemical Co., Ltd.

- China National Bluestar (Group) Co., Ltd.

- Guangdong Polysil Co., Ltd.

- Tata Chemicals Ltd.

- Heraeus Holding GmbH

- Wynca Group

- Shandong Bangde Chemical Co., Ltd.

- Yichang CSG Polysilicon Co., Ltd.

- Tonghua Shuanglong Chemical Industry Co., Ltd.

- Other Key Players

Recent Developments in the Global Fumed Silica Market

- January 2025: HPQ Silicon Inc. announced the successful completion of an internal study for its Fumed Silica Reactor (FSR) technology project. This pilot plant, developed in collaboration with PyroGenesis, is a significant milestone in fumed silica production. The facility is expected to commence operations in the third quarter of 2025, with an impressive annual output capacity of 50 tons. The new reactor aims to streamline fumed silica production while reducing environmental impact, positioning HPQ Silicon Inc. as a key player in the sustainable materials sector.

- March 2024: PyroGenesis Canada Inc. secured $0.7 million in funding from the Canadian government to develop an innovative plasma process for producing fumed silica. This funding will enable the company to scale up its advanced technology, which focuses on improving the efficiency of silica production while minimizing energy consumption. The new plasma-based process is expected to offer a more sustainable and cost-effective method compared to traditional manufacturing techniques, aligning with the growing demand for environmentally conscious production processes.

- January 2024: HPQ Silicon Inc. and PyroGenesis entered a joint venture aimed at developing a new process that will significantly reduce the energy consumption in fumed silica production by 86%. This partnership is a strategic move to improve production efficiency while reducing the environmental footprint of the silica manufacturing process. The companies plan to leverage their combined technological expertise to deliver more sustainable and cost-effective fumed silica solutions for a wide range of industries.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 1,580.2 Mn |

| Forecast Value (2034) |

USD 2,492.6 Mn |

| CAGR (2025–2034) |

5.2% |

| The US Market Size (2025) |

USD 494.4 Mn |

| Historical Data |

2019 – 2024 |

| Forecast Data |

2026 – 2034 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors, etc. |

| Segments Covered |

By Type (Hydrophilic Fumed Silica, Hydrophobic Fumed Silica), By Application (Thickening Agent, Anti-Caking Agent, Rheology Modifier, Defoamer, Desiccant), By End-Use Industry (Paints & Coatings, Adhesives & Sealants, Personal Care & Cosmetics, Pharmaceuticals, Food & Beverages, Silicone Rubber, Agriculture, Electronics) |

| Regional Coverage |

North America – US, Canada; Europe – Germany, UK, France, Russia, Spain, Italy, Benelux, Nordic, Rest of Europe; Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, Rest of MEA |

| Prominent Players |

Evonik, Cabot, Wacker Chemie, Tokuyama, OCI, Kemitura, Dongyue, Gelest, Xingfa, Xunyu, Nouryon, Shin-Etsu, Bluestar, Polysil, Tata Chemicals, Heraeus, Wynca, Bangde, Yichang CSG, Shuanglong., and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days, and 5 analysts working days respectively. |