Noise dosimeters represent a key segment within the occupational health and safety industry, driven by regulatory compliance, technological advancements, and increasing awareness of noise-related health risks. With industries and governments prioritizing worker safety and investing in technologies that foster healthier work environments, the global noise dosimeter market should experience continued expansion due to innovations making these devices more user-friendly, efficient, and versatile enough for various industrial requirements.

Global noise dosimeter market innovation continues in terms of software integration and data management capabilities. Advanced dosimeters now come equipped with cloud-based platforms and mobile applications that facilitate remote monitoring, instant notifications, and comprehensive analysis of collected data.

These features are especially advantageous in large operations with multiple monitoring points where centralized data management can streamline compliance reporting processes.

Noise dosimeter adoption has also been propelled forward by technological advancements that have enhanced their functionality and reliability.

Modern noise dosimeters come equipped with digital interfaces, real-time data logging capabilities, wireless connectivity capabilities, and integration features that work with other workplace safety systems. These features enable more efficient monitoring, data analysis, and reporting to allow employers to implement noise mitigation strategies efficiently.

Organizations and employers increasingly recognize its significance for employee well-being, absenteeism reduction, and legal liability avoidance. As this awareness has spread further noise dosimeters have become an indispensable proactive measure for monitoring occupational noise and reduction measures.

At present, the global noise dosimeter market is experiencing rapid expansion driven by regulatory requirements, technological advancements, and increased awareness of workplace safety. Noise dosimeters have become indispensable tools in monitoring and mitigating noise exposure in industrial, construction, and commercial settings due to increased emphasis on occupational health and safety regulations set by global governing bodies emphasizing more on noise exposure regulations.

Noise dosimeter technology advancements are also benefitting the market. Modern dosimeters are more compact, durable, and feature-packed than their predecessors with wireless connectivity, real-time data logging, and cloud integration capabilities. Such as Bluetooth-enabled dosimeters enabling safety managers to remotely access noise exposure information through mobile applications or central monitoring systems.

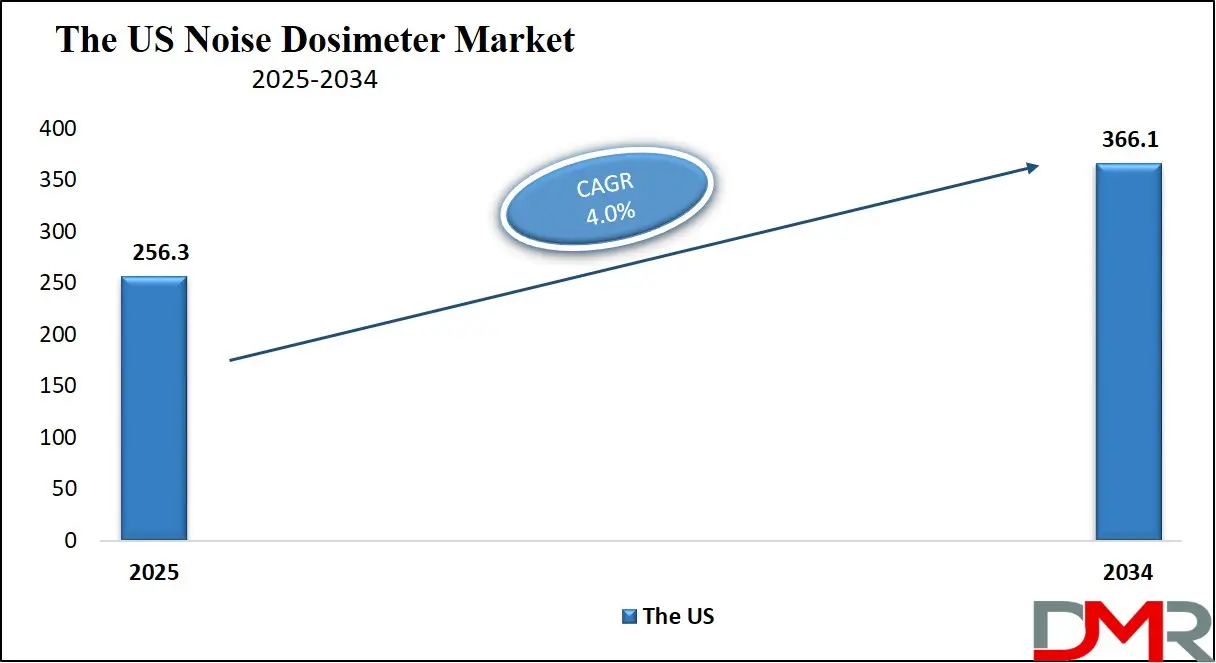

The US Noise Dosimeter Market

The US Noise Dosimeter Market is projected to be valued at

USD 256.3 million in 2025. It is further expected to witness subsequent growth in the upcoming period as it holds

USD 366.1 million in 2034 at a

CAGR of 4.0%.

The US noise dosimeter market represents an influential and advanced sector of the global market, driven by a robust regulatory framework, high industrial activity, and an emphasis on workplace safety. The US has been consistently leading in adopting innovative safety technologies like noise dosimeters to meet occupational health standards and protect workers from noise-induced hearing loss (NIHL). With its developed industrial base and strong emphasis on compliance measures, the US market continues to set benchmarks in noise monitoring practices and technological development.

US noise dosimeter sales have been driven by stringent regulatory environments. OSHA has issued comprehensive noise exposure regulations that require employers to monitor noise levels over time and protect workers from unnecessary exposures to noise levels that exceed 90 decibels (dBA) over an eight-hour time-weighted average (TWA), with hearing conservation programs mandated when noise exceeds 85dBA.

The US noise dosimeter market is also distinguished by advanced technologies. The US-based manufacturers and safety solution providers are leading the market in creating innovative noise dosimeters with features like real-time monitoring, wireless connectivity, cloud integration, predictive analytics, and usability enhancements to make noise monitoring programs more usable and effective for employers to track exposure levels remotely, analyze trends with their data proactively, proactively implement corrective measures like Bluetooth enabled dosimeters to enable safety managers to collect and review data without interrupting workers' activities for seamless monitoring process.

Global Noise Dosimeter Market: Key Takeaways

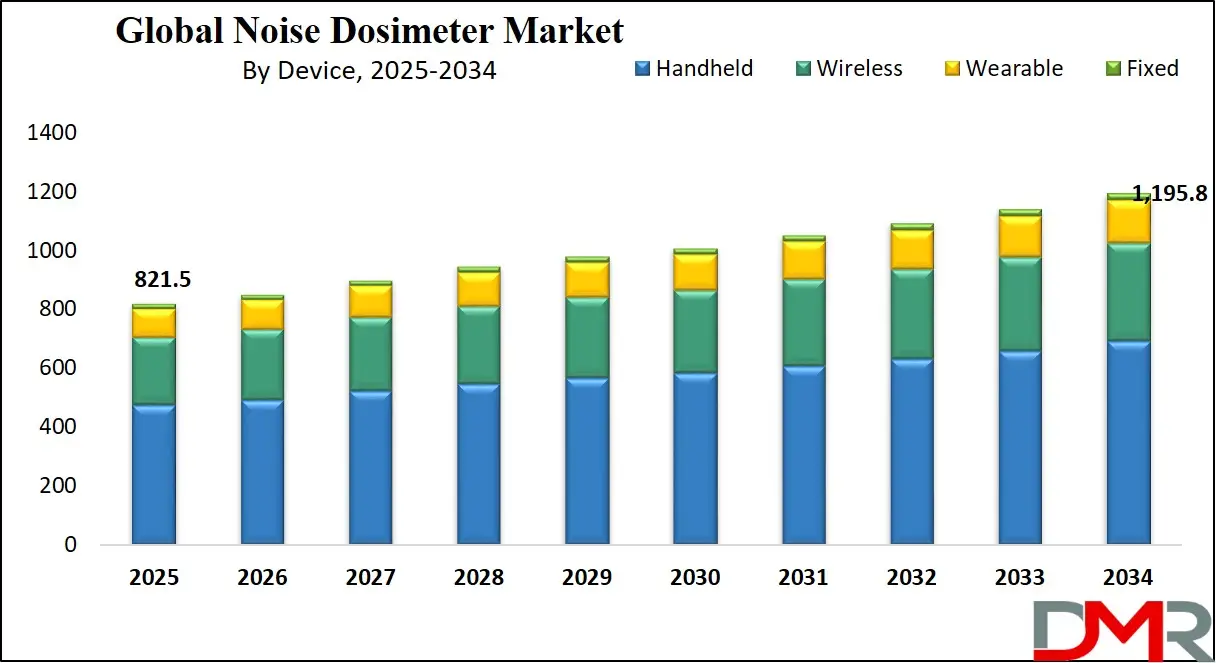

- Market Value: The global noise dosimeter market size is expected to reach a value of USD 1,195.8 million by 2034 from a base value of USD 821.5 million in 2025 at a CAGR of 4.3%.

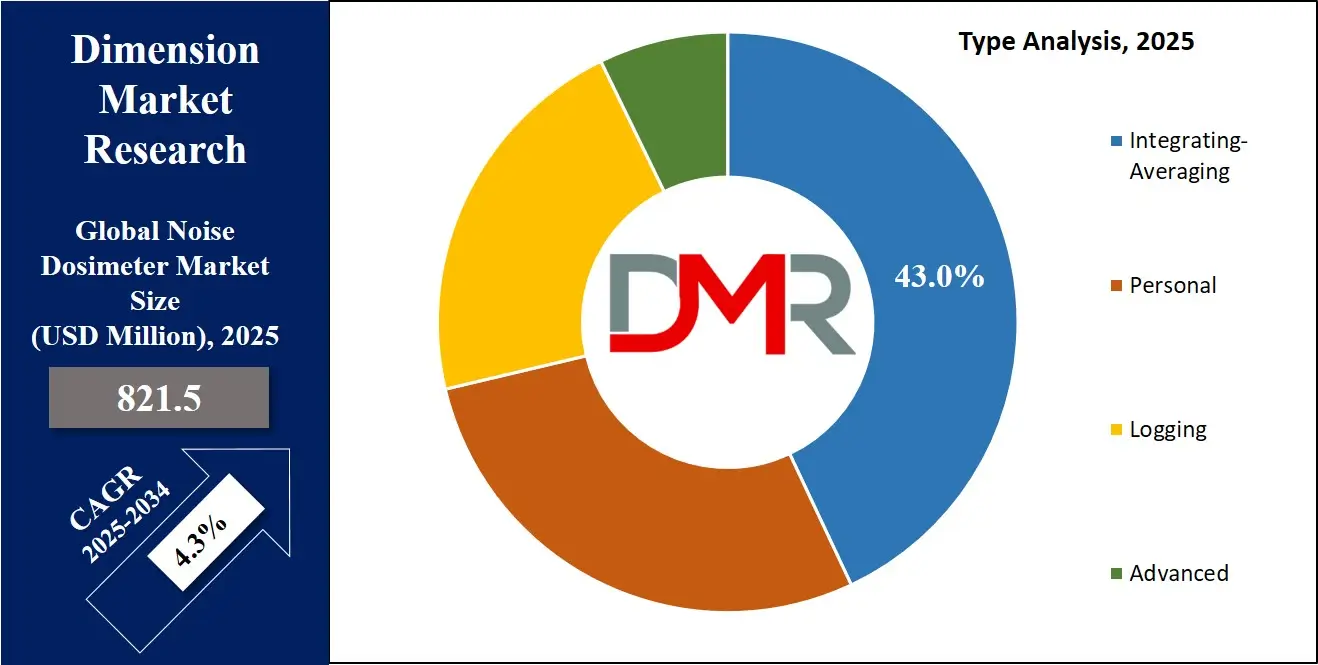

- By Type Segment Analysis: Integrating- Averaging is projected to maintain its dominance in the type segment, capturing 43.0% of the market share in 2025.

- By Software Type Segment Analysis: Integrated Software is poised to uphold its dominance in the software type segment capturing 57.0% of the total market share in 2025.

- By Device Type Segment Analysis: Handheld Devices are expected to retain their dominance in the device type segment by capturing 57.8% of the total market revenue in 2025.

- By End-Users Type Segment Analysis: Manufacturing is projected to maintain its dominance in the end-user’s type segment, capturing 36.8% of the market share in 2025.

- Regional Analysis: Asia-Pacific is anticipated to lead the global noise dosimeter landscape with 54.5% of total global market revenue in 2025.

- Key Players: Some major key players in the global noise dosimeter market are, Bruel & Kjaer A/S, Ideal Industries Inc., CESVA Instruments, 3M, SVANTEK, and Other Key Players.

Global Noise Dosimeter Market: Use Cases

- Workplace Noise Monitoring for Regulatory Compliance: Noise dosimeters are widely used in industries such as manufacturing, construction, and mining to monitor workers' exposure to noise levels and ensure compliance with occupational safety regulations. For instance, in the U.S., OSHA requires employers to adhere to permissible exposure limits (PELs) and implement hearing conservation programs when noise levels exceed 85 decibels (dBA) over an 8-hour time-weighted average. Noise dosimeters help organizations record accurate data, generate compliance reports, and avoid penalties.

- Real-Time Monitoring in High-Risk Industries: In sectors like oil and gas, aviation, and military operations, noise dosimeters equipped with real-time monitoring capabilities play a critical role in identifying immediate risks. These devices send instant alerts when noise levels exceed safe thresholds, enabling safety managers to take corrective action promptly. For example, during drilling operations in oilfields, noise dosimeters help protect workers by providing real-time exposure data and ensuring safety measures are implemented.

- Environmental Noise Impact Assessments: Noise dosimeters are also employed in environmental studies to measure noise pollution levels in urban or industrial areas. Governments and city planners use these devices to evaluate the impact of traffic, construction, or industrial noise on nearby communities. For example, before approving new construction projects, authorities may conduct noise impact assessments to ensure compliance with local noise ordinances and protect public health.

- Personal Noise Exposure Tracking: Wearable noise dosimeters are used by individual workers in industries with high noise variability, such as construction sites or entertainment venues. These devices provide personalized exposure readings, allowing workers to understand their specific risk levels. For instance, stage crew members in a concert setting can use noise dosimeters to monitor their exposure during loud performances and take breaks to avoid hearing damage.

Global Noise Dosimeter Market: Stats & Facts

- According to the Department of Health & Human Services, USA, The National Institute for Occupational Safety and Health (NIOSH) reports that over 22.0 million workers in the United States are exposed to hazardous noise levels at work each year. Exposure to time-weighted average sound levels above 85 decibels A-weighted (dBA) can lead to noise-induced hearing loss.

- According to the World Health Organization, 16% of hearing loss cases are attributed to occupational noise exposure. This percentage is higher among males (22.0%) compared to females (11.0%), reflecting the gender distribution in high-noise industries.

- According to the Centers for Disease Control and Prevention, dosimetry measurements have the highest validity coefficient (0.70) among various methods for assessing noise exposure in occupational settings. This underscores the reliability of personal noise dosimeters in accurately evaluating workers' exposure levels.

- According to the Occupational Safety and Health Administration (OSHA), the Management Information System (IMIS) database revealed an overall reduction in measured occupational noise levels over time. However, this decrease is primarily observed in the manufacturing industry, suggesting that other sectors may not have experienced similar improvements.

Global Noise Dosimeter Market: Market Dynamic

Global Noise Dosimeter Market: Driving Factors

Rising Awareness of Occupational Noise-Induced Hearing Loss

Increased awareness of occupational noise-induced hearing loss (NIHL) is emerging as an influential factor for the global noise dosimeter market. Millions of workers exposed to hazardous noise has increased demand for advanced noise monitoring solutions such as noise dosimeters among workers globally.

Noise-induced hearing loss occurs through repeated exposure to loud noise levels that damage sensitive structures within the inner ear, permanently and irreversibly compromising hearing loss. Prevention should therefore be prioritized by employers and policymakers as an integral component of workplace success.

Noise dosimeters play an essential role in the programs introduced by global bodies by providing accurate measurement and documentation of noise levels. Furthermore, European Union regulations mandate employers assess and mitigate workplace noise risks which has further increased demand for noise dosimeters.

Technological advances in noise dosimetry are also driving market dynamics. Modern noise dosimeters offer advanced features like real-time monitoring, wireless connectivity, cloud integration, and predictive analytics. These technological innovations are especially beneficial to industries with complex noise monitoring needs such as manufacturing, mining, and transportation.

Growing Stringency of Workplace Safety Regulations

Noise dosimeter sales have seen an exponential surge globally due to increased workplace safety regulations. Governments and regulatory bodies on a global scale have intensified efforts to protect workers from potentially hazardous noise exposure, realizing its harmful effect on health.

Such regulations not only create an opportunity for compliance but also drive innovation and adoption of advanced noise monitoring technologies, including noise dosimeters across various industries. Noise exposure poses a considerable threat to workers globally. High levels can result in permanent hearing damage, stress, fatigue, and reduced productivity.

Regulations like the Noise at Work Directive (2003/10/EC) in Europe, mandate employers to assess noise risks and implement protective measures if noise levels surpass certain thresholds. Other countries like Australia, Canada, and Japan have created similar rules designed specifically for their industrial landscapes that force industries to prioritize noise monitoring while encouraging them to adopt cutting-edge technologies to ensure compliance efficiently.

International regulations developed by ISO and IEC also play a significant role. Standards like ISO 9612 provide guidelines for measuring noise exposure in work environments by employing dosimeters for precise evaluation, which makes compliance with such standards especially crucial for multinational corporations operating across diverse regulatory environments, fueling the global demand for standardized noise monitoring solutions.

Restraints

High Initial Costs and Maintenance Requirements

While the noise dosimeter market is experiencing exponential growth due to regulatory mandates and increased awareness of occupational health, high initial costs and maintenance requirements act as significant barriers. Such considerations could restrict widespread adoption by small and medium-sized enterprises (SMEs) operating in regions with limited resources or less stringent regulatory frameworks.

Noise dosimeters with real-time monitoring capabilities, wireless connectivity, and cloud data storage often require initial investments. Although these devices provide accurate noise exposure measurements, their complex technology increases production costs. As such, businesses on restricted budgets may struggle to allocate funds for purchasing these devices even though they recognize their significance.

SMEs (small and medium enterprises), which make up the vast majority of industries globally, face particular financial obstacles when investing and managing noise monitoring programs effectively. Unfortunately, unlike larger enterprises, SMEs often lack sufficient financial resources and dedicated occupational safety teams necessary to invest in noise dosimeters.

As a result, many may either delay adopting dosimeters altogether or opt for cheaper or less accurate options which undermine effectiveness efforts altogether. Although governments offer incentives and subsidies to help promote occupational safety in some regions, but these policies aren't readily accessible or sufficient to cover the high costs associated with noise dosimeters. Thus, many businesses still face financial barriers to adopting them, restricting market expansion.

Lack of Standardization in Noise Measurement Methods

The lack of universal standards and practices when it comes to noise dosimetry procedures is another significant impediment in the global noise dosimeter market. While organizations such as OSHA, NIOSH, and ISO have provided guidelines for noise exposure limits, there is currently no universal standardization and practice regarding dosimetry procedures that provide consistency across industries or regulators, creating confusion for businesses, manufacturers, and regulators.

One of the major barriers to noise monitoring data reliability lies in variations between countries and regions when it comes to noise measurement criteria. OSHA in the US sets permissible exposure limits (PELs), while regulatory bodies in Europe or Asia set different PELs altogether.

Furthermore, noise dosimeters measure sound exposure differently (dBA, dBC, or equivalent continuous noise levels), making comparisons across industries difficult. Due to a wide range of noise dosimeter models on the market, each with unique features, capabilities, and calibration requirements, standardizing measurement practices has become even more complicated.

Some devices focus on personal noise exposure while others are designed for environmental monitoring or workplace noise mapping. Choosing an accurate device for individual companies' specific needs can be particularly challenging in industries with complex noise environments like construction, mining, or manufacturing.

Opportunities

Rising Focus on Worker Health and Safety in Emerging Markets

As industrialization in emerging markets accelerates, worker health and safety become more of a priority, including noise-induced hearing loss (NIHL). Governments in these regions are beginning to implement stricter workplace safety regulations while companies increasingly prioritize employee wellness, creating an ideal opportunity for the adoption of noise monitoring solutions such as dosimeters.

Emerging markets lag when it comes to occupational safety standards, especially those sectors with higher noise exposure risks like construction, mining, manufacturing, and transportation. But as these economies expand and garner global recognition, governments and regulatory bodies in emerging markets have begun adopting more stringent workplace safety regulations in line with international standards.

Major South Asian countries, for instance, have introduced laws and guidelines aimed at minimizing noise exposure at workplaces, particularly in construction and heavy manufacturing environments, leading to an increase in noise monitoring equipment (dosimeters in particular) to monitor compliance with such regulations and protect workers from hearing damage. Latin American countries have begun realizing the significance of workplace safety by adopting regulations and safety standards designed to safeguard employees against hazardous noise levels.

Growth of the Construction and Manufacturing Sectors

As urbanization increases and industrial activities boost, the construction and manufacturing sectors present an invaluable opportunity for the noise dosimeter market. Due to rising urbanization levels and industrial activities, construction and manufacturing industries are among the leading contributors to occupational noise exposure.

Therefore, these sectors exhibit strong demand for noise monitoring solutions such as noise dosimeters to safeguard worker health while complying with stringent noise regulations. Manufacturing industries including automotive, textiles, chemicals, and food processing are known for exposure to harmful noise levels.

Heavy production facilities often risk occupational noise exposure. Global industrialization increasing exponentially and expansion occurring at manufacturing facilities across Asia-Pacific, Latin America, and Middle Eastern regions resulting in greater production facilities globally requiring noise dosimeters to monitor noise levels with workplace safety regulations.

Businesses are realizing the potential of noise dosimeters; they're increasingly realizing their worth in improving productivity and worker well-being. Studies have shown that exposure to high noise levels not only causes hearing loss but can also contribute to high blood pressure, stress, and poor job satisfaction.

Trends

Integration of Wireless Technology and Real-Time Data Monitoring

One of the main trends in the noise dosimeter market is the rise of wireless technology and real-time data monitoring capabilities. As industries around the globe become more concerned with workplace safety and efficiency, dosimeters have evolved to include features that streamline the monitoring process while offering instantaneous access to crucial information.

Real-time monitoring allows companies to take proactive and accurate safety measures against noise exposure. Nowadays wireless technology has made dosimeters far simpler, providing real-time tracking of noise levels through cloud platforms or mobile applications for continuous and real-time tracking of noise levels directly, vastly improving the convenience, accuracy, and accessibility of noise monitoring.

Employers now can monitor multiple workers with wireless connectivity, eliminating the need to physically check each device individually. This real-time monitoring feature is especially beneficial in dynamic work environments like construction sites, manufacturing facilities, and mining operations where noise levels fluctuate throughout the day.

Cloud-based data storage enables employers to efficiently collect, analyze, and present noise exposure data. Long-term tracking of noise levels and patterns helps employers make informed decisions regarding workplace improvements such as investing in quieter machinery, altering processes to minimize noise hazards, or redesigning workspaces to mitigate noise exposure risks.

Shift Toward Personalization and Wearable Noise Dosimeters

Another key trend in the global noise dosimeter market is the rise of personalized, wearable devices that enable more convenient, continuous, and individual monitoring of noise exposure. As workplace safety becomes an increasing priority, industries are moving away from traditional fixed-location noise measurement tools in favor of portable and personalized solutions like wearable noise dosimeters which can easily attach to clothing or be part of their daily uniform, providing continuous tracking of individual exposure levels throughout. Wearable noise dosimeters have become increasingly attractive devices for industries where employees are regularly exposed to elevated levels of noise.

These dosimeters can be worn on workers' bodies such as belts, clothing, or helmets with sensors measuring exposure in real time. Wearable noise dosimeters offer another major advantage by continuously monitoring noise exposure levels, which can then be compared against industry guidelines and permissible exposure limits (PELs) on an individual basis This level of detail allows safety managers to quickly identify workers at risk of hearing damage, taking immediate steps, such as moving them to quieter areas or providing additional hearing protection as necessary.

Global Noise Dosimeter Market: Research Scope and Analysis

By Type

Integrating- Averaging is projected to maintain its dominance in the type segment, capturing 43.0% of the market share by the end of 2025, due to its wide application across various industries that require noise monitoring for compliance reasons.

Monitoring noise exposure in these industries is vital to worker safety as well as meeting legal compliance requirements. Integrating-averaging dosimeters are particularly useful as they measure time-weighted average (TWA) noise exposure over a specified duration, providing accurate readings that comply with regulatory standards that prioritize long-term evaluation rather than instantaneous readings. Integrating-averaging dosimeters have gained in popularity due to their user-friendliness, making these devices popular with both professionals and non-professionals.

Their intuitive design enables anyone with minimal technical expertise to use them effectively. This reduces the deployment learning curve and allows organizations to implement them more quickly across various operations.

Furthermore, this user-friendliness ensures accurate data collection which is essential for regulatory reporting purposes or noise control strategies. Technological innovations in integrating averaging Dosimeters have contributed significantly to their soaring market share. Modern devices feature advanced technologies like data logging, wireless connectivity, and real-time feedback on noise exposure levels.

By Software Type

Integrated Software is poised to maintain its dominance in the software type segment capturing 57.0% of the total market share in 2025. This dominance can be attributed to its robust capabilities, seamless functionality, and ability to meet industry requirements.

Integrative solutions offer a centralized platform that integrates noise monitoring, data analysis, and reporting into one cohesive system, eliminating the need for multiple standalone solutions and making integrated software an appealing option for businesses seeking to streamline operations. One of the primary factors driving its widespread adoption is its ability to centralize data management.

Through integrated software, users can collect, store, and analyze noise exposure data from various devices or locations simultaneously in real-time, improving efficiency as well as accuracy and consistency of data for regulatory compliance purposes.

Industries operating in noisy environments such as manufacturing, construction, and transportation benefit greatly from this feature as it simplifies monitoring noise-related risks more efficiently. Integration with existing systems is one of the main drivers behind integrated software's popularity.

Modern noise monitoring solutions need to communicate with enterprise resource planning (ERP), environmental monitoring tools, or occupational health and safety platforms seamlessly. Integrated software provides organizations with seamless connections that help maintain a coherent workflow while providing them with actionable insight from their data. This interoperability is especially useful in industries with complex operational requirements.

By Device Type

Handheld Devices are expected to maintain their dominance in the device type segment by capturing 57.8% of the total market revenue in 2025 due to their portability, versatility, and widespread application across industries. Handheld noise monitoring devices are small but accurate real-time noise measurements making them essential for numerous applications.

One of the primary factors driving handheld device popularity is their portability and convenience. Handhelds can easily be transported between settings ranging from industrial worksites, construction zones, urban planning projects, and entertainment venues, offering immediate data for decision-making purposes. They can be used for different noise monitoring tasks ranging from occupational noise exposure measurements to environmental noise assessment compliance with local regulations.

Furthermore, the versatility of handheld devices enables them to serve multiple industries simultaneously at an extremely cost-effective price point for businesses. Technological advances have vastly enhanced the functionality of handheld devices, expanding their market appeal.

Today's noise monitors come equipped with features such as real-time data display, wireless connectivity, GPS integration, and data logging capabilities that not only increase the accuracy and reliability of measurements but also facilitate seamless data transfer and analysis to align with an increasing trend toward digitalization in workplace safety and environmental monitoring.

By End-User

Manufacturing is projected to maintain its dominance in the end user's type segment, capturing 36.8% of the market share in 2025, its dominance can be explained by its prevalence of noise-related challenges within this industry. Manufacturing facilities feature heavy machinery, assembly lines, and industrial equipment which emit significant noise levels. Therefore, noise monitoring and management become essential to ensuring worker safety as well as regulatory compliance.

One key driver behind manufacturing's dominance is stringent occupational noise regulations in different regions. Agencies such as OSHA (Occupational Safety and Health Administration) in the US and similar organizations globally enforce stringent noise monitoring standards that aim to prevent hearing loss caused by noise exposure at workplaces, with manufacturing facilities using advanced noise monitoring solutions to comply with these standards and protect their workforces.

Noise exposure in such environments often changes between zones and production phases, requiring real-time monitoring to detect hotspots of noise pollution and implement targeted control measures. Modern noise dosimeters and monitoring systems offer precise insights that align perfectly with these needs, further driving their widespread adoption.

As more manufacturing companies recognize the risks associated with prolonged noise exposure, many are prioritizing investments in advanced noise monitoring technology to reduce workplace hazards while simultaneously improving employee satisfaction and productivity.

The Noise Dosimeter Market Report is segmented on the basis of the following:

By Type

- Personal

- Integrating-Averaging

- Logging

- Advanced

By Software Type

By Device

- Handheld

- Wireless

- Wearable

- Fixed

By End-Users

- Manufacturing

- Construction

- Mining

- Transportation

- Healthcare

- Military & Defense

- Entertainment

- Educational Institutions

- Research Facilities

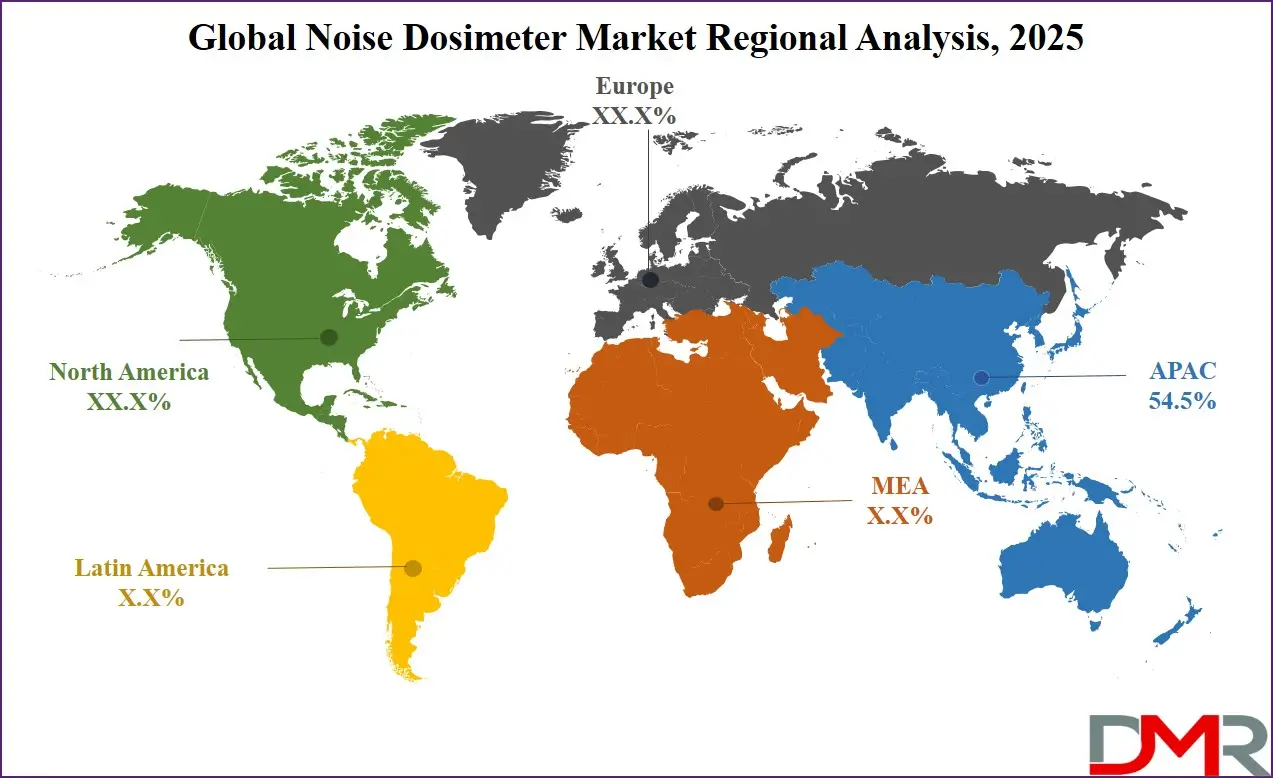

Regional Analysis

Asia-Pacific is anticipated to lead the global noise dosimeter landscape with

54.5% of total global market revenue in 2025. Its dominance can be attributed to several significant factors, including rapid economic development in China, India, Japan, and South Korea as well as urbanization trends that contribute to noise pollution within industrial, construction, and urban settings making noise monitoring and management essential components.

One key driver of Asia-Pacific's dominance is its rapid industrial and manufacturing development. Countries like China and India are global hubs for manufacturing, construction, and heavy industries that create noise pollution in the workplace.

Urbanization is also a key driver in the Asia-Pacific region. Home to some of the fastest-growing urban centers globally, Asia-Pacific hosts some of the highest construction activity levels globally. Regulatory authorities increasingly mandate noise monitoring measures at such sites to minimize impacts on workers and nearby communities creating an increasing market for noise dosimeters, especially among countries with dense urban populations.

Technological advances and the increasing affordability of noise dosimeters have catalyzed their adoption across Asia-Pacific. Local manufacturers are creating cost-effective solutions tailored to the needs of small and medium-sized enterprises (SMEs), which account for a higher share of the Asia-Pacific industrial landscape. Furthermore, training initiatives as well as government subsidies in certain regions make monitoring noise accessible across a wider segment of industries.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Global Noise Dosimeter Market: Competitive Landscape

The global noise dosimeter market is highly competitive, with several key players driving innovation and expanding their presence to establish their foothold in the market. Companies use cutting-edge technologies, strategic collaborations, and market diversification strategies to maintain leadership positions while meeting increasing demands for noise monitoring solutions.

Bruel & Kjaer is a leader in sound and vibration measurement, offering precision-engineered noise dosimeters known for their highly reliable solutions for industrial and environmental noise monitoring, making them preferred for organizations seeking compliance with stringent regulatory standards. Svantek stands out as one of the premier providers of sound and vibration instrumentation. Their noise dosimeters have earned praise from industries with stringent operational needs for technological innovation and durability.

Larson Davis from PCB Piezotronics stands out with user-friendly monitoring devices equipped with robust data collection and analysis features to support workplace safety programs seamlessly. Strategic collaborations and partnerships are integral parts of competitive strategies.

By joining forces or forming joint ventures, companies hope to enhance their technological offerings and expand into emerging markets. Partnerships between equipment manufacturers and software providers enable integrated solutions combining noise monitoring hardware with sophisticated analytics platforms and reporting platforms.

Some of the prominent players in the Global Noise Dosimeter are:

- Bruel & Kjaer A/S

- Ideal Industries Inc.

- CESVA Instruments

- 3M

- SVANTEK

- Larson Davis

- TSI

- Norsonic AS

- Cirrus Research Plc

- Extech Instruments

- Other Key Players

Global Noise Dosimeter Market: Recent Developments

- October 2024: Bruel & Kjaer A/S, a leading provider of sound and vibration measurement solutions, introduced a new line of advanced noise dosimeters designed for industrial applications. These devices offer enhanced precision and real-time data analysis capabilities, catering to the growing demand for accurate noise monitoring in the manufacturing and construction sectors.

- September 2024: 3M, renowned for its diverse product portfolio, entered into a strategic partnership with Svantek, a specialist in sound and vibration instrumentation. This collaboration aims to integrate Svantek's innovative noise monitoring technologies with 3M's safety solutions, providing comprehensive noise dosimeter products that meet stringent occupational health and safety standards.

- August 2024: Larson Davis, a division of PCB Piezotronics, announced its expansion into the Asia-Pacific region, focusing on markets such as China and India. This move is intended to capitalize on the rapid industrialization and urbanization in these countries, offering advanced noise dosimeter solutions tailored to local regulatory requirements and industry needs.

- July 2024: TSI Incorporated, a global leader in precision measurement instruments, acquired CESVA Instruments, a European-based company specializing in noise measurement technology. This acquisition aims to enhance TSI's product offerings in the noise dosimeter segment, combining CESVA's technological innovations with TSI's extensive distribution network to better serve the global market.