Market Overview

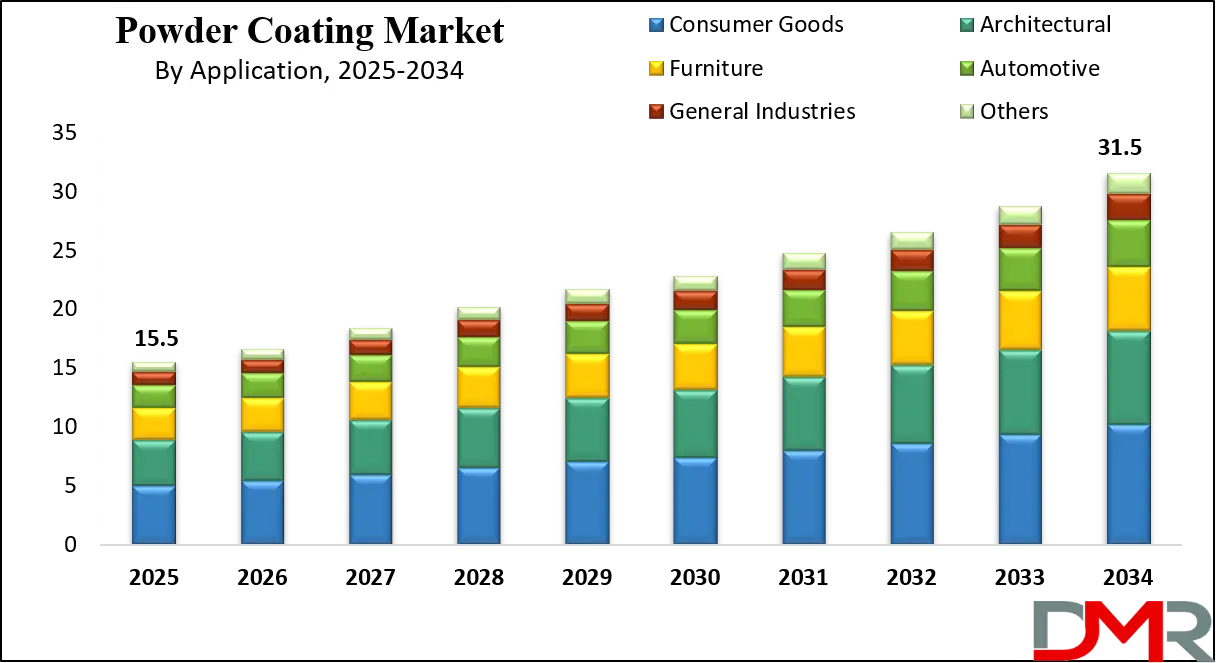

The Global Powder Coating Market is expected to reach a value of USD 15.5 billion in 2025, which is further forecasted to cross a threshold and reach the market value of USD 31.5 billion by 2034, at a CAGR of 8.2%.

The powder coating is a commonly used method to give protective coatings and decorative coatings to different items and surfaces, including metal, wood, plastic, and others. The powder coating comprises the deposition of dry, electrostatically charged powder, and the fusion to the substrate by the heat-curing operation.

The global market for the use of powder coating comprises different applications in different industries, including automotive, construction, appliances, furniture, aerospace, and other major industries. The demand for construction chemicals and specialty chemicals in parallel sectors complements the increasing adoption of powder coatings for enhanced performance and protection.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Major forces that are determining and influencing the trend of the global market for powder coating are longevity and the ability to resist different environmental conditions like corrosion and frequent wetness.

Powder coating also finds huge demand in the majority of major industries like automotive, consumer appliances, and construction due to its ability to provide various colors, textures, and quality finishes. All the above impact the demand and supply, pricing, and general operation of the global market for powder coating.

The rules, laws, and standardization by different global and governmental bodies strongly impact the market for powder coating because they oversee the entire chain from the manufacture to the channel of distribution. Thus, the laws affect the world market for powder coating in a twofold manner because they are most likely to break market trends, and at the same time, they offer opportunities and challenges to the market.

As awareness among consumers about the harmful effects of conventional paint on health and the environment is gaining prominence, consumers have become interested in the use of powder coating because the latter is green and eco-friendly. Additionally, the increasing use of antimicrobial coating technologies is driving adoption in healthcare and food-processing applications.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

The US Powder Coating Market

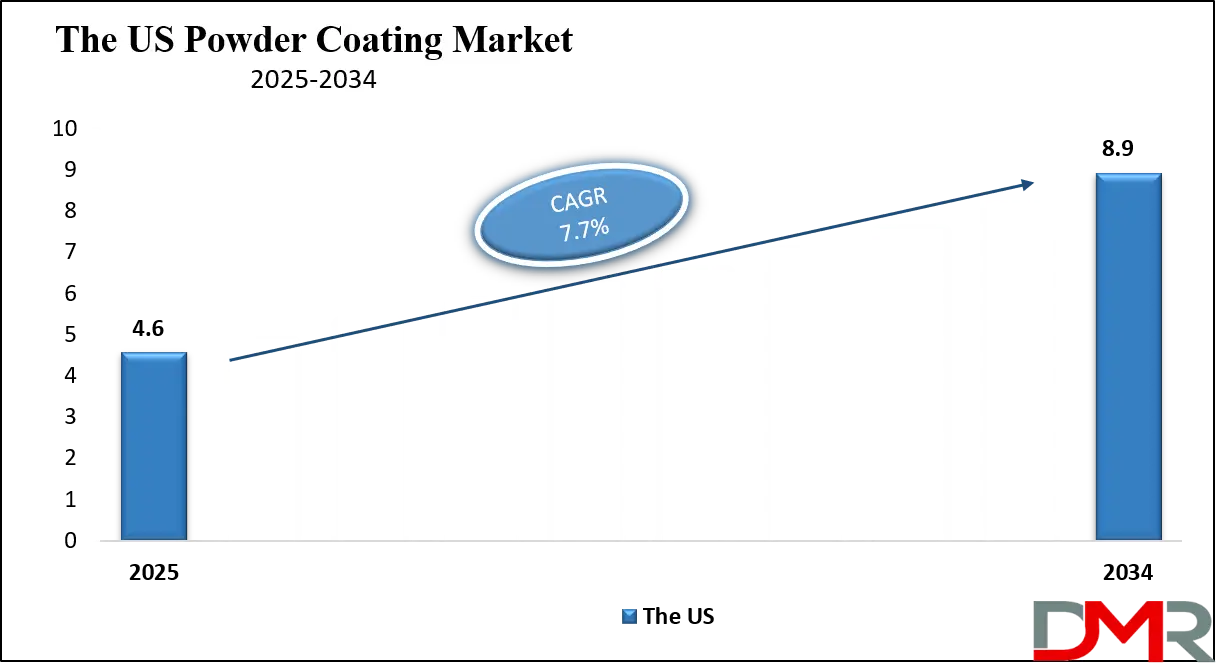

The US Powder Coating Market is anticipated to be valued at USD 4.6 billion by the end of 2025 which is further expected to grow up to USD 8.9 billion in 2034 at a CAGR of 7.7%.

The U.S. market for powder coatings continues to grow steadily, based on the escalating demand for long-lasting, eco-friendly coatings in numerous industries. The coatings are commonly applied in the automotive, consumer products, furniture, appliance, construction, and industrial segments because they are longer-lasting, corrosion-resistant, and less harmful to the environment than liquid coatings. Increasing adoption of industrial automation and manufacturing efficiency systems further supports the application of powder coatings across production facilities.

The demand is boosted by the escalating use in the automotive and appliance industries, in which manufacturers are looking to use less costly and high-performing coatings. The greater emphasis on green and the imposition of tough environmental laws, such as the limitation of the use of volatile organic compounds (VOCs), are also driving industries to use less-solvent-based coatings and opt for the use of powders.

The U.S. market also has the benefit of developments in the formulation of powders, resulting in greater quality, longevity, and recyclability. The market also uses automatic coating lines to increase efficiency and suppress costs. The demand for energy-conserving appliances and electric vehicles (EVs) also provides new opportunities in the applications of powder coatings.

Demographically, the growth in the U.S. manufacturing sector, urbanization, and disposable income are driving demand for quality-coated products. The market dominance by major players and R&D investments also spur the rate of innovation, making the U.S. the world's leading market in terms of powder coating technology. The country’s growing automotive plastic compounding and automotive parts packaging sectors also indirectly benefit powder coating adoption.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Key Takeaways

- Global Market Size Insights: The Global Powder Coating Market is expected to reach a market value of USD 15.5 billion by the end of 2025.

- The US Market Size Insights: The US Powder Coating Market is anticipated to reach a market value of USD 8.9 billion by the end of 2034 from the base value of USD 4.6 billion in 2025.

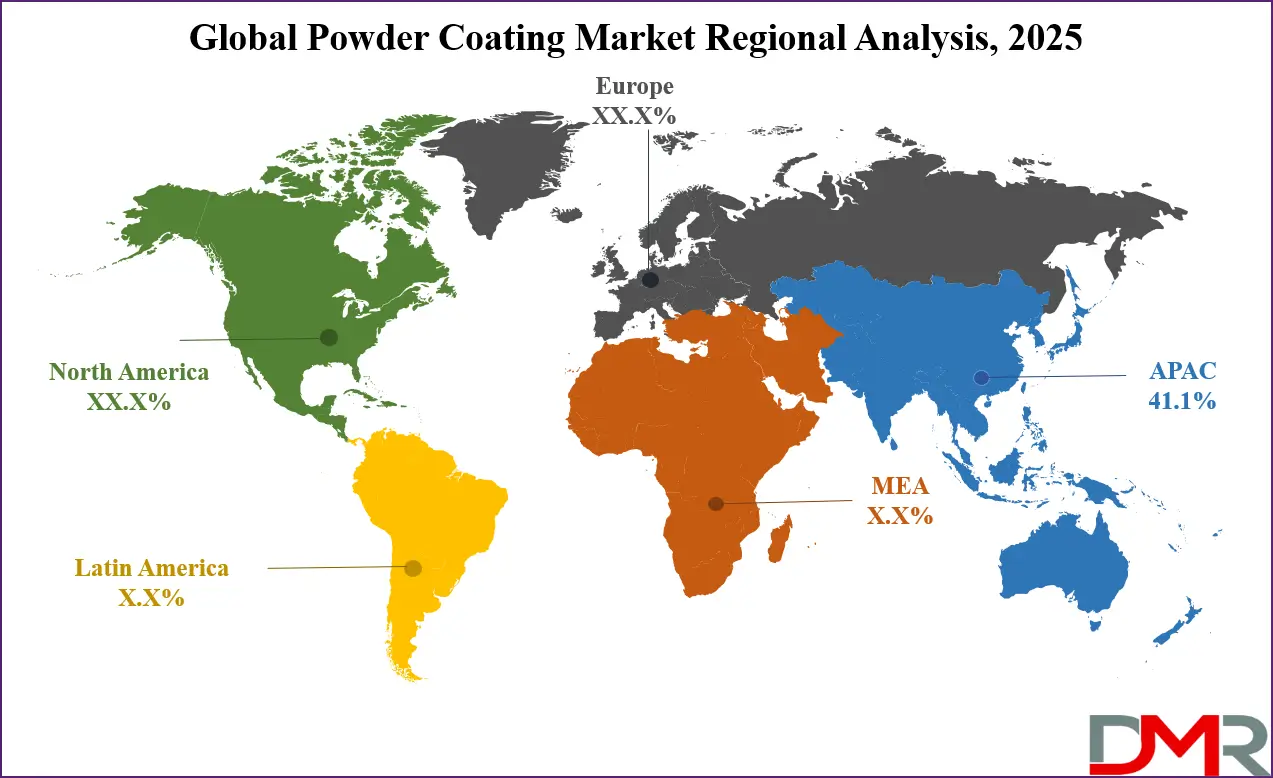

- Regional Insights: Asia-Pacific is projected to dominate the global powder coating market as it held 41.1% of the market share in 2025 and is expected to show subsequent growth in the upcoming years as well.

- Key Players Insights: Some of the major key players in the Global Powder Coating Market are Akzo Nobel N.V., PPG Industries Inc., BASF SE, Jotun, The Sherwin-Williams Company, DSM, Valspar Arkema S.A., Bayer AG, TCI Powder, Berger Paints India Limited, Nippon Paint Holdings Co. Ltd, Asian Paints PPG Pvt Limited and others.

- The Global Market Growth Rate: The market is growing at a CAGR of 8.2 percent over the forecasted period.

Use Cases

- Automotive Industry: Powder coatings enhance the longevity of the vehicle, shielding it from corrosion, chemicals, and extreme weather. It coats wheels, the chassis, bumpers, and other components, and gives a good finish while having less effect on the environment relative to liquid coatings.

- Consumer Electronics: Powder coatings offer protection and enhance the aesthetics of electronics, such as laptops, cell phones, and home appliances. The smooth, long-lasting, and eco-friendly finish offers extended product life and resistance to wear, abrasions, and chemical damage.

- Architectural Applications: Widely used for aluminum extrusions, window frames, doors, and building facades, powder coatings offer superior durability and UV resistance. They contribute to sustainable construction by providing low-maintenance, long-lasting protection with minimal environmental impact.

- Industrial Equipment: Powder coatings offer high-performing protection to tools, piping, and equipment in heavy-industrial applications. Chemical, heat, and abrasion resistance by the coatings enhance the life expectancy of the equipment and offer efficient operation in the manufacturing and oil & gas industries.

- Furniture Industry: Applied to metal and wood furniture, powder coatings offer a durable, attractive, and eco-friendly finish. The coatings are resistant to scratching, color retention, and weatherproofing, making them ideal for indoor and outdoor furniture applications in both residential and commercial settings.

Market Dynamic

Global Powder Coating Market: Driving Factors

Rising Demand from Automotive and Consumer Goods Sectors

The global market for powder coatings also continues to see significant growth, bolstered by the booming automotive and consumer appliances markets. The automotive segment's use of powder coatings in wheels, the chassis, engine components, and body parts, among others, gives them greater corrosion resistance, longer lifespan, and good aesthetics.

The use of EVs and the imposition of tighter fuel efficiency and emission regulations are also driving automakers to light-weight and green coatings, and driving demand for powder coatings.

Similarly, the consumer appliances, home appliances, and electronics segment are fueling market growth. The market provides excellent scratch resistance, heat resistance, and color retention, and the coatings are most suitable for applications in kitchen appliances, washing machines, and kitchen cabinetry.

The increase in purchasing power and lifestyles in developing economies in nations like India, China, and Brazil is also fueling demand for premium quality-coated products, reflecting long-term market growth. This trend parallels the rise of industrial and institutional cleaning chemicals, which ensure equipment longevity in related industries.

Stringent Environmental Regulations Favoring Powder Coatings

Global governments and regulators are applying tough environmental laws in favor of the use of powder coatings in comparison to solvent-based coatings. Traditional liquid coatings are burdened with VOCs and harmful air pollutants (HAPs) and are significant sources of air pollution and health risks to workers.

Powder coatings, in contrast, are low to zero in terms of the content of VOC and are the solution of choice in industries interested in the green agenda. Emerging cold gas spray coating methods also complement the eco-friendly transformation of coating technologies.

Policies such as the U.S. EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP), the European Union’s Green Deal, and China’s "Blue Sky" environmental policies are driving manufacturers toward sustainable coating alternatives.

Additionally, the rising adoption of circular economy principles encourages the use of recyclable, low-waste coatings, further boosting powder coatings’ market growth. As industries strive to meet global sustainability targets, powder coatings continue to gain traction as a cost-effective, environmentally responsible solution for multiple applications.

Global Powder Coating Market: Restraints

High Initial Investment and Equipment Costs

While powder coatings are long-term money-savers, the enormous up-front investment in equipment and infrastructure serves to deter most manufacturers, and most significantly the small and medium enterprises (SMEs). The transition from conventional liquid coatings to the use of powder coatings requires specialized electrostatic spray guns, curing furnaces, and recuperation units, and this calls for enormous investments.

Additionally, customizing the color and texture of the powders demands sophisticated factory facilities and accurate formulation skills, further driving up the cost. It also inhibits many businesses from embracing the use of powders because they are costly and demand expert technicians to run specialized equipment. This economic limitation decelerates market entry, most noticeably in price-conscious markets and industries with less available funds.

Challenges in Coating Complex and Heat-Sensitive Substrates

One of the most significant problems in the market for powder coatings is the limitation in applying coatings to detailed geometries and heat-sensitive surfaces. Since the powder coatings are to be heat-cured at high temperatures (typically 160–200°C or 320–392°F), some surfaces such as plastics, composites, and some woods are limited in terms of absorption.

Although advancements in low-temperature curing powders are attempting to remedy this issue, they are currently in their infancy and are in the improvement process to provide the same quality of performance as conventional high-temperature powders. It also provides the challenge to provide consistent thickness in coatings in intricate, recessed, and multilayer surfaces, leading to defects in the form of orange peel texture, uneven coverage, and poor adhesion.

Industries that require highly flexible or hybrid coatings, such as electronics, medical devices, and automotive components, are unable to transition fully to powder coatings due to the above limitations. It shall be crucial to the long-term market growth to overcome the above technological challenges through R&D and new application techniques.

Global Powder Coating Market: Opportunities

Expansion in Emerging Markets and Infrastructure Development

Rapid urbanization and industrialization in the developing economies of nations such as India, China, Brazil, and Southeast Asia provide enormous opportunities to the market for powder coatings. Higher disposable income, construction activity, and booming automotive industries are driving demand in the nations in the shape of quality coatings. The governments are investing significantly in the development of smart cities, infrastructure, and transportation networks, further driving the demand for corrosion-resistant, long-lasting coatings.

The growing consumer in the middle class in the affected countries also fuels demand in the market for home appliances, electronics, and upscale furniture, all based on the use of the premium finish through the use of powder coatings. The global shift in the geographical location of the plants to Asia-Pacific due to the low cost of manufacture and the availability of qualified workers also offers opportunities to gain market share in the high-growing nations.

Rising Adoption of Powder Coatings in Renewable Energy Applications

The global transition to renewable energy sources is leading to opportunities in the world of solar energy, wind energy, and EV infrastructure. The solar panel industries are employing the use of powder coatings to a greater extent to cover the mounting frames, frames, and inverters to combat extreme climatic and corrosive conditions. Similarly, the components in the case of the wind turbine, the blade, tower, and nacelle, also require extremely resistant coatings to combat extreme climatic exposure.

With governments and enterprises around the world making investments in clean energy infrastructure, the demand for high-quality coatings to enhance longevity and efficiency continues to surge. The rapid deployment of EV charging stations also demands ultraweather-resistant coatings to encapsulate charging units and connected infrastructure. The improved resistance to ultraviolet light, chemicals, and heat by the use of powder coatings makes them the most suitable to encapsulate renewable energy equipment, driving market demand further.

Global Powder Coating Market: Trends

Shift Toward Sustainable and Eco-Friendly Coatings

The global market for powder coatings is also exhibiting a significant trend in the direction of eco-friendly, green solutions, fuelled by tightening environmental laws and consumer pressure to use green products. The use of zero to minimal volatile organic compounds (VOC) in powder coatings minimizes air pollution and ensures greater occupational health and safety in comparison to conventional liquid paints.

Government regulation, including the REACH regulation in the European Union and the tough U.S. EPA emission laws, are compelling industries to use powder coatings in place of conventional liquid paints. The use of bio-based powders from renewable sources by manufacturers also reduces the environmental impact of the industry. As businesses focus on achieving carbon neutrality and minimizing waste, the use of powder coatings globally is expected to gain pace.

Technological Advancements in Powder Coating Formulations

Continuous R&D activity drives developments in the formulation of powders, advancing the performance, quality, and versatility of applications. The most current developments are low-temperature curing powders, making possible the coating of heat-sensitive surfaces such as wood and plastics, and expanding market applications. Advances in the use of nano-coatings also offer improved scratch resistance, anti-corrosive, and protection from the effects of the sun's ultraviolet rays, making their use in the automotive, aerospace, and construction industries appealing. The market also contemplates the use of self-healing coatings and anti-microbial powders, answering the needs of hygiene-driven industries such as healthcare and food processing. The developments increase the efficiency of the coating, energy savings, and lifespan, driving the trend in the market's growth.

Research Scope and Analysis

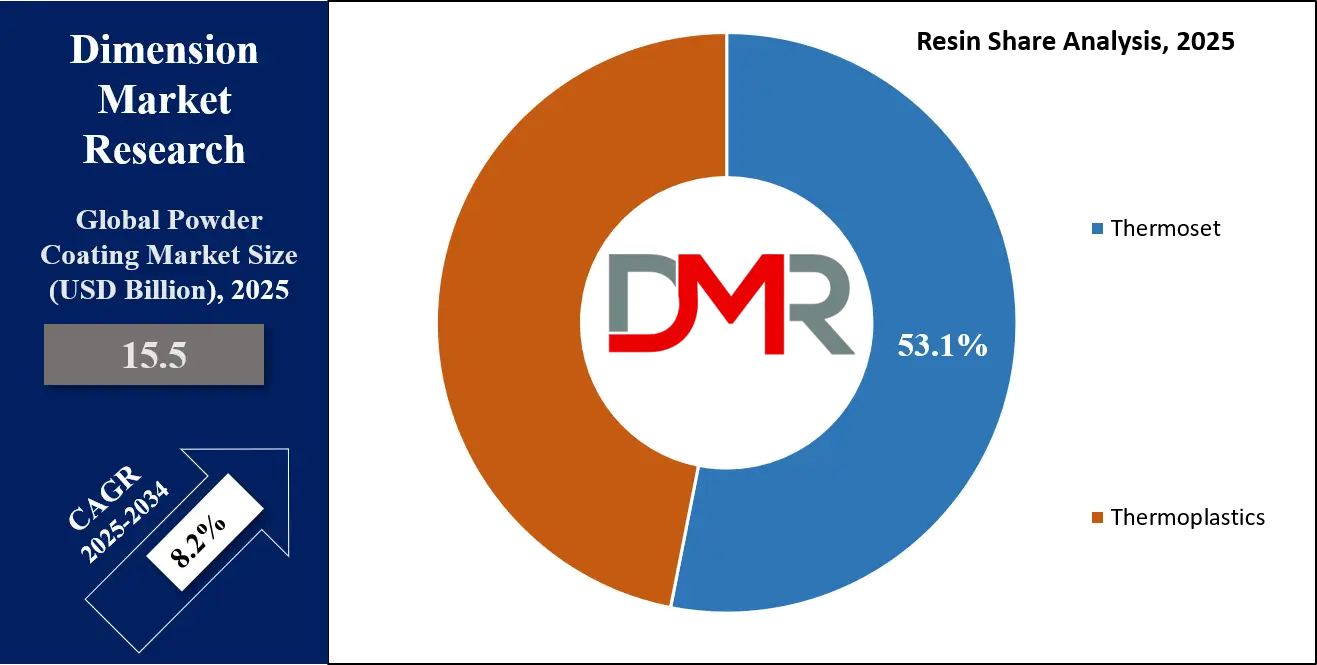

By Resin

Thermoset resins are projected to be the market leader in the global market for powder coatings, commanding a 53.1% market share in 2025 and expected to experience further growth in the future. The thermoset powder coatings, such as epoxy, polyester, and acrylic, are the most sought-after because they are extremely resistant to wear and tear, chemicals, and offer good adhesion.

The thermoset coatings, when applied to a surface and dried, become a permanent cross-linked structure and are extremely resistant to chipping, cracking, and discoloration. This makes thermoset coatings the most appropriate for applications in the outdoors and in industries, where long-term protection from extreme environmental elements is necessary.

Among thermoset types, the most commonly used are epoxy-based powders because they are resistant to corrosion and chemicals and are suitable for use in applications in the marine, oil & gas, and equipment industries.

The polyester coatings are resistant to ultraviolet light and the elements and are most widely used in applications in architecture, automotive components, and outside furniture. The acrylic thermoset coatings are most famous for having good retention of gloss, smooth surfaces, and color, and are most often used in automotive clear coats and consumer appliances.

Thermoset resins are also gaining greater applications because they are easily applied to various substrates, including metal, plastics, and wood. Being economically efficient and having high-performing traits, they are the priority in industries demanding coatings to resist extreme heat, water, and chemicals. The applications in automotive, construction, and other industries are constantly on the rise, and the demand in the future years in the market for thermoset-based powders is expected to surge significantly.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

By Coating Method

The electrostatic spray coating process is the most commonly used in the market to coat powders and is poised to experience steady growth in the future. It finds extensive use due to the efficiency, precision, and cost savings in terms of the material. The process in this case uses a dry powder coating, which gets an electrostatic charge and gets applied to the ground substrate. The employment of the electrostatic charge helps the powder particles get consistently attracted to the surface, leading to smooth coverage, less overspray, and less wastage of the material.

One of the major advantages of the use of electrostatic spray coating is the efficiency in the transfer of the coating, and in most applications, only a single layer is enough to achieve a good quality finish. This saves the money and effort involved in applying multiple layers.

The method also provides consistent thickness in the coating, and this is required in industries requiring consistent surface protection, such as automotive, aerospace, and heavy equipment. The process also minimizes the risks in the workplace and the environment and encourages environmental responsibility because the use of solvents containing volatile organic compounds (VOCs) is eliminated.

Due to the great resistance to corrosion and toughness, the use of electrostatic spray coatings in appliances, metal furniture, fencing, and automotive parts is prevalent. The industries also gain from the variety in color and texture possible through the use of this process, allowing the manufacturers to personalize the finishes to suit customer demands. Additionally, automation and robotic developments in the use of electrostatic spray coating are making the process cheaper and more efficient, further fueling the use in the market for powder coatings.

By Application

The consumer electronics segment is projected to possess 32.2% of the market share in the global market, in 2025. The consumer electronics segment comprises a diverse range of items, including smart devices, wearables, home appliances, kitchen appliances, gaming consoles, and electronics. All the above are aided by the use of powder coatings because they are highly resistant to wear and tear and also provide wonderful aesthetics.

One of the most powerful drivers of the consumer product use of powder coating is the color, texture, and finish it provides. Aesthetic appeal drives consumer purchasing, and in the smartphone, laptop, video console, and home furnishing industries, the use of the product helps to attain sleek, upscale aesthetics and offers a long-term, scratch-resistant finish. It also offers improved resistance to fade, chip, and corrosion, and the product's appearance and structure are intact in the long term.

Powder coatings also increase the lifespan and durability of home appliances and electronics. Home appliances and electronics, including fridges, washing machines, and kitchen appliances, require coatings resistant to heat, water, and a scratch-resistant finish. The heat and chemical resistance provided by the powder coatings make them the most suitable coatings to use in such applications.

Furthermore, the demand for consumer items having low-VOC, eco-friendly coatings also spurred the shift to the use of powder coatings. Along with urbanization, disposable income, and demand for premium consumer items, the use of the consumer segment's powder coatings in the future shall increase significantly.

The Powder Coating Market Report is segmented based on the following:

By Resin

- Thermoset

- Polyester

- Epoxy

- Epoxy-Polyester (Hybrid)

- Acrylic

- Polyurethane

- Others

- Thermoplastics

- Polyvinyl Chloride (PVC)

- Nylon

- Polyolefin

- Polyvinyl Fluoride (PVF

By Coating Method

- Electrostatic Spray

- Fluidized Bed

- Others

By Application

- Consumer Goods

- Architectural

- Furniture

- Automotive

- General Industries

- Others

Regional Analysis

Region with the Highest Market Share

Asia-Pacific is poised to dominate the market globally in terms of market share in 2025, holding 41.1% of market revenue and is expected to exhibit further growth in the future years. Asia is a global manufacturing hub having various developed and developing nations, such as China, India, Japan, and South Korea, having numerous major industries.

The region possesses a well-advanced infrastructure of various industries, such as automotive, consumer appliances, and construction, driving the demand for the use of powder coating because the use of the same in the manufacturing process is inevitable.

The region underwent huge economic progress and urbanization in the past decades, resulting in construction and infrastructure developments. The increase in the industries also fuels the increase in the use of powder coating.

Also, various manufacturers are drawn to this region because the same provides them the advantage of less manpower, making the whole process cheaper. The use of the same also reduces the wastage and makes the process efficient.

Asia's dominance in the market of the use of the same is the result of the strong industrial foundation, economic progress, consumer demand, and greater focus on sustainability which collectively make this region a key region in the global powder coating industry.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Region with the Highest CAGR

North America is projected to show the highest CAGR in the global powder coating market due to advances in the world's technology, stringent environmental regulations, and the increase in use in industries. The United States and Canada are also witnessing the demand for long-term, green coatings, and the demand comes from the automotive, aerospace, consumer products, and building industries.

One of the most significant drivers of the market is the use of powder coatings instead of traditional liquid coatings, which contain volatile organic compounds (VOCs) in them. Strict EPA regulations and corporate practices to become more sustainable are fueling the shift to low-emission, high-performing coatings. The demand from the emerging North American EV market, which demands corrosion-resistant and energy-saving coatings, also drives market demand.

Moreover, the region hosts leading powder coating manufacturers investing in the latest formulation, automation, and robotic applications, enhancing efficiency and quality. Due to the rapid industrialization, infrastructure, and demand for quality consumer products, North America is expected to experience steady growth in the future.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The Global Powder Coating Market competes in a competitive market with the presence of major players, who are undertaking organic and inorganic strategies to enhance market dominance. In organic strategies, the major players are focusing on research and development in the segment of power coating by developing the formulation, techniques, and texture. The case in point in inorganic strategies is mergers, partnerships, and acquisitions of new and small businesses, which have good opportunities to enhance their domain and position in the global market.

The major players offer diverse products in the segment of powder coating to meet the demand from the automotive, construction, and consumer product industries. This diversification in the applications in various industries gives the product a broader consumer market and many opportunities to enhance in the future.

The competitive market in the segment of powder coating is dynamic because the major market players and local players are dominating the market. The major drivers in gaining a competitive advantage in the market are the adaptability to the market demand and consumer preferences along with the assurance to provide quality.

Some of the prominent players in the global Powder Coating Market are:

- Akzo Nobel N.V.

- PPG Industries Inc.

- BASF SE

- Jotun

- The Sherwin-Williams Company

- DSM

- Valspar Arkema S.A.

- Bayer AG

- TCI Powder

- Berger Paints India Limited

- Nippon Paint Holdings Co. Ltd

- Asian Paints PPG Pvt Limited

- Other Key Players

Recent Developments

- September 2023: PPG Industries, Inc. announced an expansion of its powder coating production capacity to meet the growing global demand. This strategic move aims to enhance PPG's ability to serve various industries requiring high-quality powder coatings.

- April 2024: Arkema presented a wide range of sustainable solutions and technologies at the American Coatings Show, held from April 30 to May 2, 2024, in Indianapolis, Indiana. The showcase emphasized Arkema's commitment to supporting customers' decarbonization efforts and sustainability goals.

- March 2023: PPG Industries introduced the Envirocron Primeron Primer, designed to provide high corrosion resistance for metal substrates, including steel. This product launch reflects PPG's ongoing commitment to innovation in protective coatings.

- March 2023: MÜNZING Chemie became an associate member of the European Producers of Laminate Flooring (EPLF). This membership allows MÜNZING to align the development of its FENTAK® additives for the wood processing industry with current trends and stay updated with upcoming regulatory changes.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 15.5 Bn |

| Forecast Value (2034) |

USD 31.5 Bn |

| CAGR (2025–2034) |

8.2% |

| The US Market Size (2025) |

USD 4.6 Bn |

| Historical Data |

2019 – 2024 |

| Forecast Data |

2026 – 2034 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors, etc. |

| Segments Covered |

By Resin (Thermoset, Thermoplastics), By Coating Method (Electrostatic Spray, Fluidized Bed and Others), By Application (Consumer Goods, Architectural, Furniture, Automotive, General Industries and Others) |

| Regional Coverage |

North America – US, Canada; Europe – Germany, UK, France, Russia, Spain, Italy, Benelux, Nordic, Rest of Europe; Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, Rest of MEA |

| Prominent Players |

Akzo Nobel N.V., PPG Industries Inc., BASF SE, Jotun, The Sherwin-Williams Company, DSM, Valspar Arkema S.A., Bayer AG, TCI Powder, Berger Paints India Limited, Nippon Paint Holdings Co. Ltd, Asian Paints PPG Pvt Limited, and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days, and 5 analysts working days respectively. |

Frequently Asked Questions

How big is the Global Powder Coating Market?

▾ The Global Powder Coating Market is expected to reach a market value of USD 15.5 billion by the end of 2025.

Which region accounted for the largest Global Powder Coating Market?

▾ Asia-Pacific is projected to dominate the global powder coating market as it held 41.1% of the market share in 2025 and is expected to show subsequent growth in the upcoming years as well.

Who are the key players in the Global Powder Coating Market?

▾ Some of the major key players in the Global Powder Coating Market are Akzo Nobel N.V., PPG Industries

Inc., BASF SE, Jotun, The Sherwin-Williams Company, DSM, Valspar Arkema S.A., Bayer AG, TCI Powder,

Berger Paints India Limited, Nippon Paint Holdings Co. Ltd, Asian Paints PPG Pvt Limited and others.

What is the growth rate in the Global Powder Coating Market?

▾ The market is growing at a CAGR of 8.2 percent over the forecasted period.