Market Overview

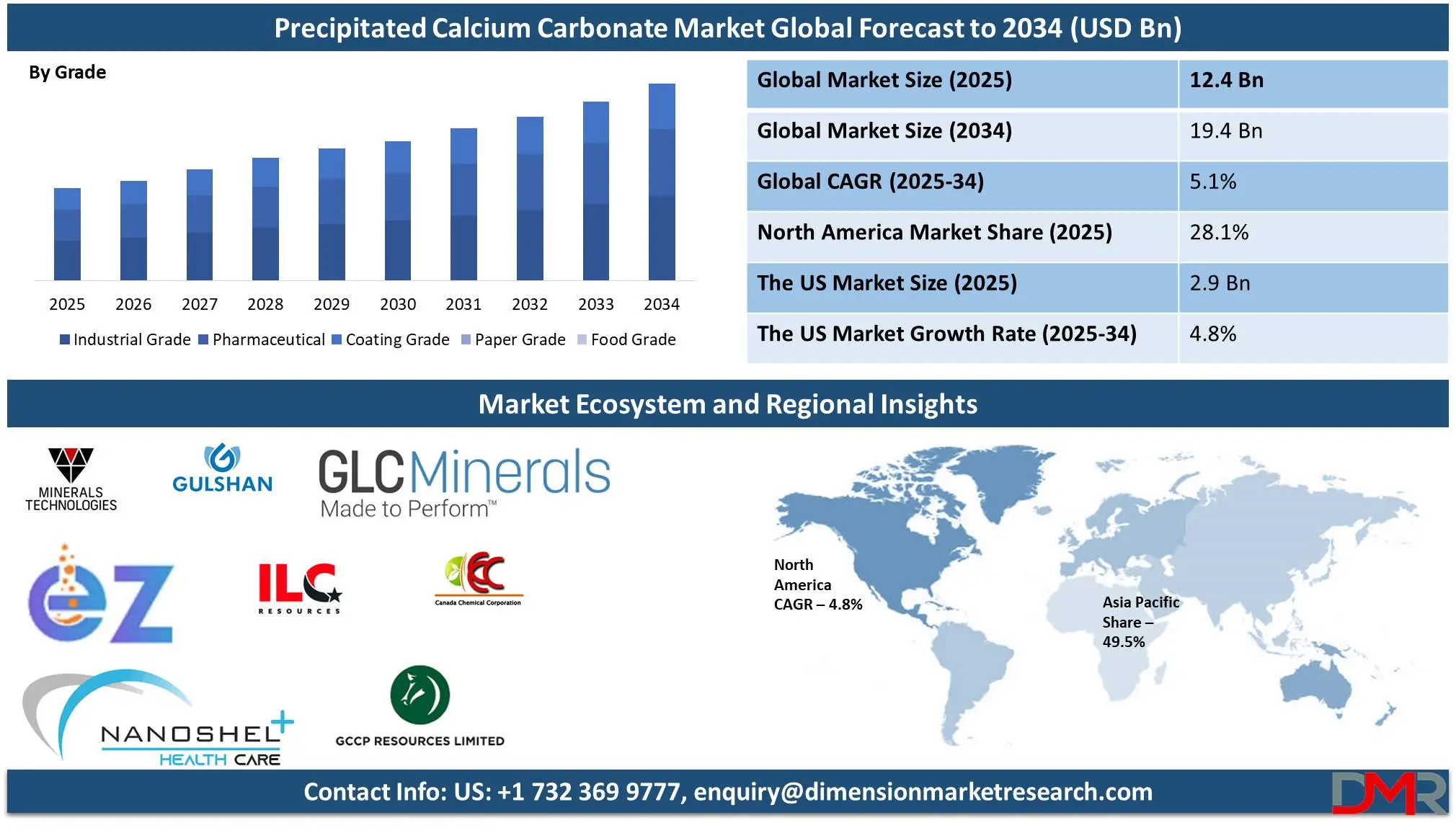

The Global Precipitated Calcium Carbonate Market is predicted to be valued at

USD 12.4 billion in 2025 and is expected to grow to

USD 19.4 billion by 2034, registering a compound annual growth rate

(CAGR) of 5.1% from 2025 to 2034.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Precipitated Calcium Carbonate, shortened as PCC, is a pure, synthetic calcium carbonate produced through a process of calcium hydroxide and carbon dioxide chemical precipitation. With its great whiteness, brightness, and fine particle size, it is ideal for paper, plastic, paint, adhesives, and drug industry usage. With its tailored-made properties, fine control of particle morphology is achievable, which enhances the functionality and esthetic attractiveness of end-products. With its great quality, predictable functionality, and capability of enhancing mechanical properties and optical properties in various industries, it makes end-products stronger, more resistant, and more beautiful, which in turn makes it a highly desired material in various market sectors, and it gives guaranteed efficiency.

Global demand for Precipitated Calcium Carbonate (PCC) is rising due to its industrial applications, in paper, plastics, and the construction industry. The capability of PCC in contributing to enhanced product quality in an environmental-friendly process makes it a desired additive. With industries emphasizing being sustainable and regulatory-compliant, demand for PCC is destined to go upward. The opportunities exist in technology advancement in manufacturing, cost reduction, and broader applicability in new industries in emerging economies such as in environmental cleansing and pharmaceuticals. With technology constantly improving, there is a healthy market for PCC, which keeps on rising steadily along with new opportunities for applicability throughout the entire world. This portends a sustainable future.

The US Precipitated Calcium Carbonate Market

The US Precipitated Calcium Carbonate Market is projected to be valued at USD 3.9 billion in 2025. It is expected to witness subsequent growth in the upcoming period as it holds USD 5.9 billion in 2034 at a CAGR of 4.8%.

The U.S. Precipitated Calcium Carbonate (PCC) market is driven by increasing demand from industries such as paper, plastics, paints, and pharmaceuticals. The growing need for lightweight and durable materials in the automotive and construction sectors boosts PCC adoption. Additionally, advancements in nanotechnology enhance PCC’s functional properties, driving its use in high-performance applications. Rising environmental concerns and sustainability initiatives encourage manufacturers to replace conventional fillers with PCC, reducing carbon footprints. The expansion of the packaging industry further accelerates market growth.

The rising preference for ultrafine PCC in pharmaceuticals and personal care products is expanding its application scope. The demand for high-brightness PCC in premium paper and coatings is also increasing. The integration of PCC in bioplastics and biodegradable materials aligns with green initiatives. Market players also invest in advanced surface modification techniques to enhance PCC’s performance.

Precipitated Calcium Carbonate Market: Key Takeaways

- Market Growth: The global Precipitated Calcium Carbonate market is anticipated to expand by USD 6.4 billion, achieving a CAGR of 5.1% from 2026 to 2034.

- Grade Analysis: Industrial grade is predicted to dominate the precipitated calcium carbonate with the highest revenue share by the end of 2025.

- Application Analysis: Paper is set to lead the Global Precipitated Calcium Carbonate (PCC) with the highest revenue share in 2025.

- Regional Analysis: Asia Pacific is projected to dominate the Global Precipitated Calcium Carbonate Market, holding a market share of 49.5% by 2025.

- Prominent Players: Some of the major key players in the Global Precipitated Calcium Carbonate Market are Minerals Technologies Inc., CANADA Chemical, ILC Resources, and many others.

Precipitated Calcium Carbonate Market: Use Cases

- Paper Industry: PCC serves as a coating pigment and filler in the paper industry. It enhances brightness, opacity, and smoothness, which in turn improves print quality and overall appearance.

- Plastics and Rubber: In the plastics and rubber sectors, PCC is used as a filler to improve mechanical properties, reduce production costs, and enhance the durability of the final products.

- Paints and Coatings: PCC is incorporated into paints and coatings as a pigment extender and filler. Its addition improves the whiteness, opacity, and overall consistency of the coating, resulting in a smoother finish and better coverage.

- Pharmaceuticals and Personal Care Products: Due to its high purity and consistent particle size, PCC is used in pharmaceutical formulations and personal care items. It acts as an excipient or filler in tablets, toothpaste, and cosmetics, contributing to product stability and performance.

Precipitated Calcium Carbonate Market: Stats & Facts

- According to the European Federation of Pharmaceutical Industry and Association, the pharmaceutical markets in China, Brazil, and India experienced growth rates of 11.3%, 4.8%, and 10%, respectively, between 2015 and 2020.

- The National Investment Promotion & Facilitation Agency states that India’s beauty and personal care sector ranks as the eighth largest globally, valued at approximately USD 15 billion. This market is projected to grow at a CAGR of 12-16% in the coming years. Additionally, the Hong Kong Trade Development Council reports that China is the second-largest consumer of cosmetics and personal care products, contributing to roughly 17.3% of the world's total consumption.

- According to the European Industrial Pharmacists Group, pharmaceutical production in Europe surged from USD 135.3 billion in 2000 to USD 318.4 billion in 2021. This growth was accompanied by increases of 11.7% in France, 6.7% in Germany, and 11.8% in Italy.

- Mineral Technologies Inc. has agreed with India-based Satia Industries to establish a satellite PCC plant with a production capacity of 42,000 metric tons per year at Satia’s paper mill in India. This initiative is expected to enhance Mineral Technologies’ presence in the Asia-Pacific region.

- As per FORBES, the U.S. is one of the world's largest beauty markets, accounting for 20% of the global industry share, followed by China and Japan. Furthermore, Atradius Collections, a global trade-invoice-collection services firm, highlights that the U.S. pharmaceutical sector contributed approximately 22% of global production in 2022, positioning the country as a key market for PCC demand growth.

Precipitated Calcium Carbonate Market: Market Dynamic

Driving Factors in the Precipitated Calcium Carbonate Market

Growing Demand in the Paper IndustryThe demand for Precipitated Calcium Carbonate (PCC) is being fuelled by a healthy paper industry demand, in which it is being used as a filler and a printing pigment for adding brightness, opacity, and printing. With rising demand for paper of a high quality and environmentally friendly nature, there is a preference for using PCC due to its ability to replace fibers of wood, making paper making it cost-friendly and environmentally friendly. The thriving packaging industry, driven by growth in the e-commerce industry and a shift in customer preference for paper packaging, is fueling demand for PCC further. The trend is here to stay as there is an increase in focus on being sustainable in the packaging and printing industries.

Increasing Usage in Pharmaceuticals and Personal Care

PCC is a vital element in personal care and pharmacy due to its purity, controlled size, and stability of chemicals. In pharmacy, it is widely used as an excipient in formulations of medicines, calcium supplements, and active ingredient in antacids. The non-toxic and bio-compatibility of its attributes make it an imperative additive in medicines. In personal care, it is used in toothpaste, cosmetics, and skincare as a moderate abrasive, an opacifying agent, and a whitening agent. The growth of the cosmetic and healthcare industries, particularly in emerging economies, is fueling the usage of PCC in these industries.

Restraints in the Precipitated Calcium Carbonate Market

Stringent Environmental Regulations

Environmental regulations associated with Precipitated Calcium Carbonate (PCC) production pose substantial obstacles to market expansion. Limestone extraction and its processing as part of PCC production both contribute to carbon emissions, prompting tighter environmental regulations worldwide. Governments and regulatory bodies enforce stringent emissions control measures, waste disposal standards, and carbon taxation rates that increase operational costs for manufacturers. Industries are exploring sustainable and bio-based alternatives that could decrease PCC usage over time and curb demand in the long term. Businesses must invest in carbon-neutral production methods to comply with regulations while remaining cost-competitive on the market.

Volatility of Raw Material Prices

The PCC industry relies heavily on limestone and carbon dioxide as raw materials, both of which may experience price variations over time. Supply chain disruptions, geopolitical conflicts, energy price surges, and transportation costs all play an enormous role in material availability and pricing decisions. Unexpected jumps in fuel and electricity expenses further compound production expenses while diminishing profitability in PCC manufacturing companies. Market volatility renders long-term pricing strategies difficult and contracts with end users unpredictable; to address these risks companies are exploring alternative sourcing strategies, recycling processes, and local production hubs as ways to guarantee cost stability and consistent supply in the PCC market.

Opportunities in the Precipitated Calcium Carbonate Market

Expansion in Plastics and Polymer Business

Increased usage of Precipitated Calcium Carbonate (PCC) in plastics and polymers is opening big market opportunities. The mechanical properties, temperature stability, and impact resistance of plastics are enhanced, and production costs are reduced when using PCC as a reinforcing filler. The plastic composites of packaging, automobile, and household industries now employ PCC for making plastic products stronger and of enhanced performance. The trend is enhanced due to a shift toward sustainable and lightweight materials since plastics filled with PCC reduce carbon footprints by replacing non-sustainable, heavy material options. The process capability is enhanced using PCC, which provides improved molding, extrusion, and enhanced plastic product surface finish.

Advances in Nanotechnology and Specialty Grades

Newer technologies in nanotechnology have given rise to Nano-Precipitated Calcium Carbonate (NPCC), which gives improved functionality in a large number of industrial end-products. NPCC’s improved surface area, smaller size, and enhanced dispersive properties enhance material functionality, making it a highly sought-after pharmacy, adhesives, paints, coatings, and rubbers additive. NPCC enhances mechanical strength, opacity, and viscosity adjustment in formulations significantly. Specialty grades of PCC tailored for industry-specific applications, such as ultra-pure grades for medical, and high-bright PCC for high-quality paints, are being developed. This enables manufacturers to diversify in niche markets and enhance competitiveness, and returns in the business of PCC.

Trends in the Precipitated Calcium Carbonate Market

Shift towards Sustainable and Eco-Friendly PCC Production

Sustainable practices have increasingly taken center stage within the Precipitated Calcium Carbonate (PCC) market as industries strive to lessen their environmental footprint. Manufacturers are investing more and more in carbon-neutral production methods, using CO2 sequestration technologies to minimize emissions during PCC synthesis and thus help lower their industrial carbon footprint and support global climate change mitigation efforts. This trend also aligns with global efforts for climate change mitigation efforts. Recycling technologies are also being implemented to make PCC production more resource-efficient, thus decreasing raw material dependence. Bio-based alternatives that utilize sustainable sources are becoming popular as industrial applications implement circular economy principles into production facilities.

Precipitated Calcium Carbonate Market: Research Scope and Analysis

By Grade

Industrial grade is predicted to dominate the precipitated calcium carbonate with the highest revenue share by the end of 2025, due to its applicability in a wide number of industrial industries and cost-effectiveness. Usage in paper manufacturing, paints and coatings, plastics, rubber, adhesives, and construction materials is driving active demand. The grade is developed in various purity, particle size, and custom-made properties for adjustment in different processing requirements wherein absolute purity is not a necessity. Consistent operation is ensured due to quality checks, and lower requirements about pharmacy grade make it cost-effective for manufacturing. Such aspects make industrial grade take a leadership position in precipitated calcium carbonate in the market throughout the globe, ensuring consistency.

Pharmaceutical-grade precipitated calcium carbonate is anticipated to be the second largest in dominance due to its vital position in large medical uses. High purity and stringent quality checks ensure safety and effectiveness in drugs, medicine, and food. Strict regulatory requirements call for the following permissible levels of contaminants and narrow distributions of particulate size, so it is a necessity for tablet, capsule, and suspension formulations.

By Application

Paper is set to lead the Global Precipitated Calcium Carbonate (PCC) with the highest revenue share in 2025, due to its vital role in paper production as a filler and a coating. The paper is improved in its brightness, smoothness, and printing capability using PCC, making it highly sought after in paper production of high quality. The increase in demand for green, sustainable paper material is also driving growth in utilizing PCC since it is a green alternative for standard fillers. The paper industry growth, particularly in printing and packaging, is driving additional demand for PCC.

Plastic is expected to be the second-largest segment for PCC due to its widespread usage in various sectors of industry, including automobile, construction, and consumer. PCC enhances plastic properties by simplifying its processing and replacing more expensive fillers. With an increase in plastic material requirements for being light in weight, tough, and possessing great performance, plastic usage of PCC as a reinforcing material and an extender are on a constant upward trend. The growth of the plastic industry in emerging economies is another prime driver for the plastic usage of PCC.

The Precipitated Calcium Carbonate Market Report is segmented based on the following

By Grade

- Industrial Grade

- Pharmaceutical

- Coating Grade

- Paper Grade

- Food Grade

By Application

- Plastics

- Paper

- Rubber

- Paints & Coatings

- Pharmaceuticals

- Adhesives & Sealants

- Others

Regional Analysis

Region with the largest Share

Asia Pacific is likely to lead the Precipitated Calcium Carbonate market with a revenue

share of 49.5% by the end of 2025, due to its robust industrial activity and diverse sector demand. China, in particular, boasts an expansive manufacturing base that drives significant PCC demand across many different sectors such as paper production; plastic injection molding; tire molding; high volume automotive component production using PCC as filler/reinforcing agents that enhance material properties while decreasing costs; rapid pharmaceutical sector expansion spurred on by rising healthcare expenditure as part of expanding middle classes increases market penetration further ensuring continued dominance and market expansion across Asia Pacific resulting in sustained dominance/market expansion over time in Asia Pacific.

Region with Highest CAGR

North America is projected to experience the highest compound annual growth rate (CAGR) in the Precipitated Calcium Carbonate market, largely due to its expanding pharmaceutical sector. An aging population and rising healthcare expenditure are fueling increased demand for advanced drug delivery systems and high-quality tablet formulations. As a critical excipient, PCC is essential in ensuring product performance and stability. The region’s focus on innovation, regulatory support, and technological advancements further drive adoption in both established and emerging markets. Consequently, these factors combine to accelerate market growth and secure a prominent growth trajectory. Overall, strong industry fundamentals underpin robust regional expansion.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The Precipitated Calcium Carbonate industry comprises a significant number of major players as well as leading competitors. Moreover, it can be noted that key players participate in leading strategic innovations, product developments, collaborations, mergers, and acquisitions to achieve the element of competitiveness in the market as well as to strengthen their positions and expand the market throughout the geographies. On the other hand, the level of competition can be determined as highly competitive. Additionally, it is also possible to note that there is a significant element of competition and rivalry amongst existing players, as they are in the process of acquiring a higher percentage of shares. Moreover, key players in the industry are mainly in rivalry regarding market share gain of competition and strategies related to institutional competition.

Some of the prominent players in the global Precipitated Calcium Carbonate are

- Fujian Sanmu Nano Calcium Carbonate Co., Ltd.

- Guangdong Qiangda New Materials Technology Co.

- Minerals Technologies Inc.

- NanoMaterials Technology

- EZ Chemicals Inc.

- Nanoshel LLC

- GCCP Resources Ltd.

- Gulshan Polyols Ltd.

- GLC Minerals

- CANADA Chemical

- ILC Resources

- Other Key Players

Recent Developments

- In July 2023, Minerals Technologies Inc. partnered with a global paper manufacturer to upgrade its precipitated calcium carbonate facility in Brazil by incorporating MTI’s NewYield LO PCC technology.

- In April 2023, Omya India, a prominent calcium carbonate producer, announced a $25 million investment in a state-of-the-art calcium carbonate plant in Gujarat. This significant investment aims to boost production capacity and improve efficiency, reinforcing Omya India’s dedication to delivering high-quality products to meet growing market demand.

- In August 2022, Cimbar Resources Inc. acquired the calcium carbonate production assets of U.S.-based Imerys Carbonate Inc. in Arizona. This acquisition allowed Cimbar Resources to expand its product portfolio and enhance its ability to serve customers from multiple locations.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 12.4 Bn |

| Forecast Value (2034) |

USD 19.4 Bn |

| CAGR (2025-2034) |

5.1% |

| Historical Data |

2019 – 2024 |

| The US Market Size (2025) |

USD 2.9 Bn |

| Forecast Data |

2025 – 2033 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Grade (Industrial Grade, Pharmaceutical, Coating Grade, Paper Grade, and Food Grade), By Application(Plastics, Paper, Rubber, Paints & Coatings, Pharmaceuticals, Adhesives & Sealants, and Others) |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia- Pacific– China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA

|

| Prominent Players |

Fujian Sanmu Nano Calcium Carbonate Co., Ltd., Guangdong Qiangda New Materials Technology Co., Minerals Technologies Inc., NanoMaterials Technology, EZ Chemicals Inc., Nanoshel LLC., GCCP Resources Ltd., Gulshan Polyols Ltd., GLC Minerals, CANADA Chemical, ILC Resources,and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users) and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |

Frequently Asked Questions

How big is the Global Precipitated Calcium Carbonate Market?

▾ The Global Precipitated Calcium Carbonate Market size is estimated to have a value of USD 12.4 billion in 2024 and is expected to reach USD 19.4 billion by the end of 2033.

Which region accounted for the largest Global Precipitated Calcium Carbonate Market?

▾ Asia Pacific is expected to be the largest market share for the Global Precipitated Calcium Carbonate Market with a share of about 49.5% in 2024.

Who are the key players in the Global Precipitated Calcium Carbonate Market?

▾ Some of the major key players in the Global Precipitated Calcium Carbonate Market are Minerals Technologies Inc., CANADA Chemical, ILC Resources, and many others.

What is the growth rate in the Global Precipitated Calcium Carbonate Market?

▾ The market is growing at a CAGR of 5.1 percent over the forecasted period.

How big is the US Precipitated Calcium Carbonate Market?

▾ The US Precipitated Calcium Carbonate Market size is estimated to have a value of USD 2.9 billion in 2024 and is expected to reach USD 4.5 billion by the end of 2033.