Refractory materials are advanced ceramic substances designed to withstand intense chemical corrosion, high temperatures, & mechanical stress. By providing mechanical durability, resistance to corrosion, & thermal insulation, they play a vital yet often underestimated role in the daily operations of nearly every industry. These materials have proven indispensable for numerous sectors in establishing crucial manufacturing processes, including iron and steel, cement, various metals, glass, paper & pulp, and petrochemicals.

In certain sectors such as steel and other metals, these items are treated as consumables & need periodic replacement to function properly. Conversely, sectors like glass & cement consider their long-term investment as they can serve their purpose for up to a decade.

Refractory materials are pivotal for the advancement of diverse end-use sectors due to their non-toxic production methods, with over 90% of them being recycled or reused. However, the market for these materials faced challenges due to the impact of the COVID-19 pandemic, given its reliance on cement, glass, steel, & metal manufacturing, as well as mining, heavy industry, & oil and gas sectors.

Key Takeaways

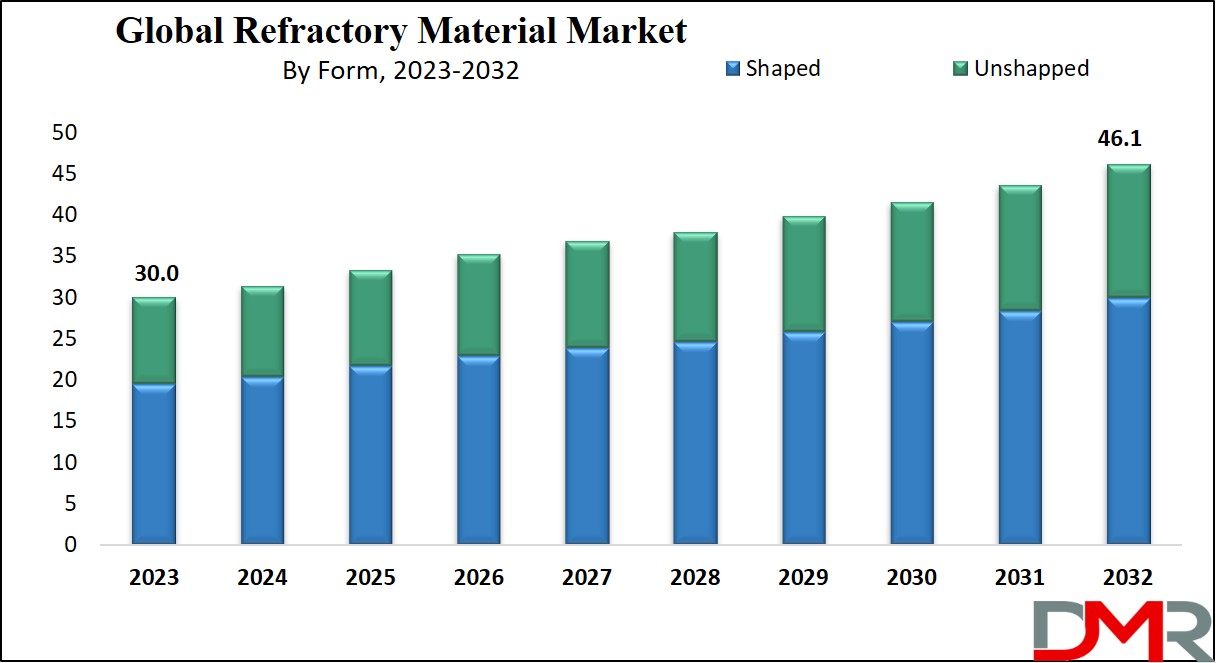

- Market Size & Share: The Global Refractory Material Market size is expected to be worth around USD 46.1 Billion by 2033 from USD 30 Billion in 2023, growing at a CAGR of 4.9% during the forecast period from 2024 to 2033.

- Form Analysis: Under the form segment, the shaped segment emerges as the primary revenue contributor and is expected to dominate throughout the projected period.

- Product Analysis:The clay segment holds a larger market share due to its lower cost compared to the non-clay segment.

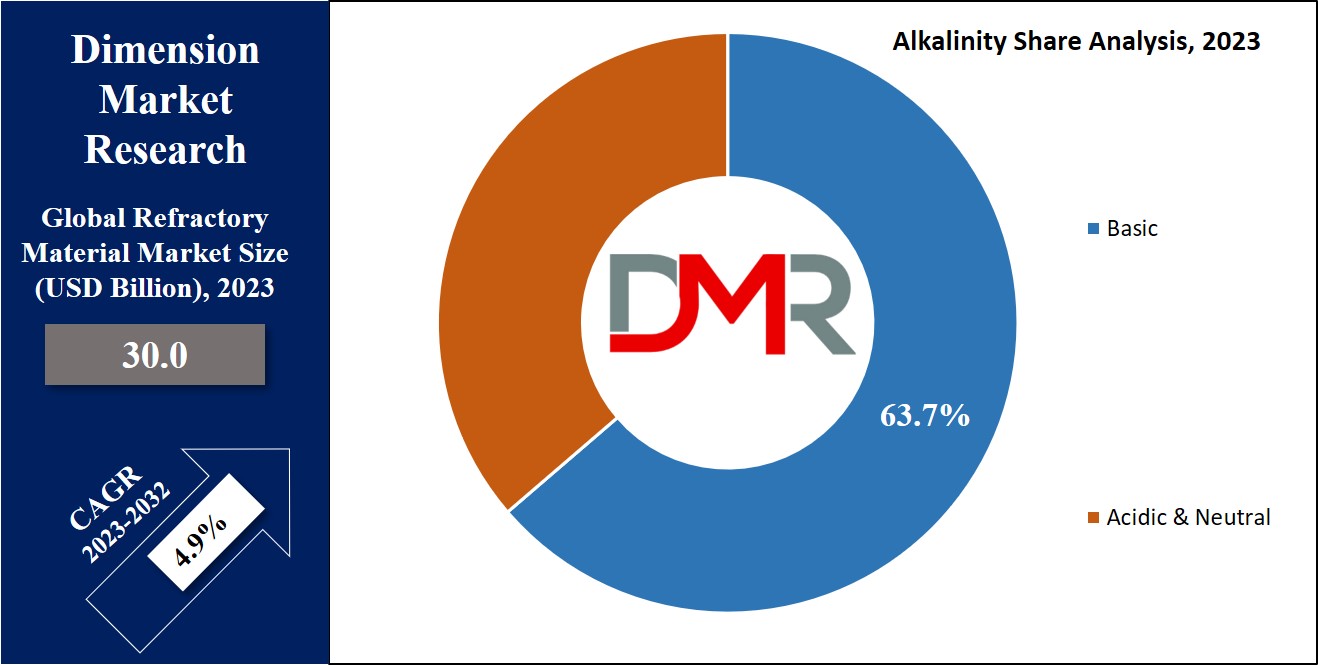

- Alkalinity Analysis: Under the alkalinity segment, the basic category dominates the market share in 2023.

- End-User Analysis: The iron and steel sector commands the most significant portion of this market due to its extensive usage in virtually all furnaces, reactors, and vessels employed in steel production.

- Regional Analysis:The Asia-Pacific region accounts for 82.3% of the market share in 2023.

Use Cases

- Steel & Metallurgy Industry: Used in blast furnaces, ladles, and converters to withstand extreme temperatures and protect equipment from wear and corrosion.

- Cement & Lime Production: Applied in rotary kilns and clinker coolers to maintain structural integrity under high heat conditions.

- Glass Manufacturing: Used in glass melting furnaces and regenerators to resist thermal shock and chemical corrosion.

- Petrochemical & Chemical Industry: Installed in reactors, incinerators, and refining units to handle high-temperature processing of chemicals and fuels.

- Power Generation (Including Waste-to-Energy Plants): Utilized in boilers, gasifiers, and incinerators to enhance efficiency and prolong equipment lifespan under extreme thermal conditions.

Market Dynamic

The Global Refractory Materials Market is experiencing growth due to rising investments in the iron and steel sectors. This growth is evident in developed and emerging nations such as the United States, China, & India, where refractory materials are widely employed for thermal insulation purposes. The surge in iron and steel production is attributed to rapid infrastructure development and increased demand from the automotive industry.

A major driving force in the refractory materials market is the consistent growth in steel industries. Despite refractory materials costing slightly higher, approximately two to three percent more than steel, the expanding infrastructure, along with thriving oil and gas and automobile sectors, is fueling the development of the steel industry.

While opportunities persist in cement, glass, & non-ferrous sectors for refractory businesses, the steel industry significantly influences their success. Currently, three-fourths of the global demand for refractories stems from the steel industry, a dominance expected to persist throughout the entire projection period.

The ecological impact of raw materials used in refractories like carbon, carbides, silica, ceramic fibers, and similar substances is substantial. Prolonged contact with ceramic fibers can lead to adverse health effects such as respiratory issues, skin irritation, &, in extreme cases, fatalities. Furthermore, the manufacturing process of refractories emits hazardous pollutants, like nitrogen oxides & carbon monoxide, which adversely affect the environment.

Another challenge that persists is overproduction affecting steel sectors. Despite challenges, there has been a gradual recovery over the past year. Moreover, due to the focus on self-reliance and reducing imports, investments in the steel industry are anticipated to rise in emerging & underdeveloped nations, further driving the demand for refractory materials.

Driving Factors

The global refractory material market is driven by expansion in industries like steel, cement and glass that consume large volumes of refractories products such as furnace liners. Refractories play an essential role in high temperature industrial processes by providing durability and heat resistance within furnaces, kilns and reactors; rising construction activities especially in developing regions have increased cement demand which in turn increased demand for refractories.

Furthermore renewable energy investments necessitate advanced solutions that use advanced refractories creating sustained demand across various industrial applications for various industrial applications for use across many industrial applications for these applications just some examples

Trending Factors

Trend WATCH Refractory material manufacturers are rapidly transitioning toward eco friendly refractories as part of an effort to comply with stringent environmental regulations and produce eco friendly materials with lower carbon footprints and longer lifespans. Recyclable and non toxic refractory materials are becoming more widely utilized as industries prioritize sustainability.

Furthermore, digital technologies, including predictive maintenance systems and monitoring systems are being integrated into refractory applications to enhance performance and reduce downtime. Together with increasing adoption of lightweight refractories in energy intensive industries, these innovations represent a market trend towards efficiency, sustainability and advanced performance capabilities.

Restraining Factors

One of the key obstacles facing the refractory material market is price fluctuations of raw materials such as high purity alumina, silica and magnesia, which is susceptible to supply chain disruptions and geopolitical tensions that lead to increased costs and market instability.

Refractory production involves energy intensive processes which are further affected by rising energy costs and stringent emissions regulations; high manufacturing expenses as well as maintaining consistent quality standards can limit growth potential especially among smaller producers or cost sensitive industries.

Opportunities

Emerging economies present significant opportunities in the refractory material market due to rapid industrialization and infrastructure development. Countries throughout Asia Pacific and the Middle East are witnessing increased investments in steel, cement and petrochemical industries spurring demand for advanced refractory solutions.

Renewable energy sources present new opportunities, as refractories play an essential role in manufacturing components for solar, wind, and hydrogen energy systems. Furthermore, innovations like

nanotechnology and

3D printing are broadening their application scope even further by offering tailored high performance solutions for modern industrial challenges opening new growth possibilities.

Research Scope and Analysis

By Form

Under the form segment, the shaped segment emerges as the primary revenue contributor and is expected to dominate throughout the projected period. Shaped refractory materials offer platforms with intricate designs & larger surface areas or honeycomb patterns. These structures help in the exposure of metal catalysts to reactive gases or reactants.

Industries requiring highly effective thermal insulation solutions, in conjunction with these unique designs, opt for shaped refractory materials. For example, sectors like iron and steel manufacturing, cement production, and glass manufacturing favor shaped refractory materials for superior thermal insulation in kilns, incinerators, furnaces, and reactors. This trend is propelling the growth of this segment in the global market.

By Product

In terms of products, the market is categorized into clay and non-clay segments. The clay segment holds a larger market share due to its lower cost compared to the non-clay segment. Products such as fireclay bricks & insulation materials are typically crafted from clay materials and are extensively used by producers in the iron & steel industry.

Additionally, raw materials for producing refractory clay items are more easily accessible, further contributing to its dominance in the market. Specific manufacturing methods involve strong acids & bases, making non-clay refractory products highly resistant to corrosion. They offer superior corrosion resistance compared to their standard clay counterparts.

By Alkalinity

Under the alkalinity segment, the basic category dominates the market share in 2023. Basic refractory materials are utilized in areas where the surroundings & slags have alkaline conditions. They find application in both offshore and onshore structures, such as incinerators, kilns, chemical manufacturing facilities, & the metal fabrication sector, due to their stability in alkaline environments, making them valuable for thermal insulation purposes. This factor propels the global market for basic refractory materials.

By End-User

Under the end-user segment, the market is segmented into the following sectors, Iron & Steel, Non-Ferrous Metals, Glass, Cement, and Others. The iron and steel sector commands the most significant portion of this market due to its extensive usage in virtually all furnaces, reactors, and vessels employed in steel production.

Additionally, the refractory lining is regularly replaced, occurring every half hour - 2 days, at different stages of the steel manufacturing process. This leads to substantial consumption by the iron and steel industry.

The advancement of glass melting technology hinges primarily on the progress & caliber of refractory goods. Selecting the right refractory material is paramount when constructing a glass furnace, given that the furnace's longevity is directly contingent on the quality of the refractory material.

AZS (Alumina Zirconia Silica) serves as the fundamental structural refractory material for glass furnaces, mainly because molten glass does not readily adhere to it and does not react with it. The growing glass industry, driven by a shift towards eco-friendly alternatives over plastics, is boosting the need for refractory materials.

The Refractory Material Market Report is segmented on the basis of the following

By Form

By Product

By Alkalinity

By End-User

- Iron & Steel

- Non-Ferrous Metals

- Glass

- Cement

- Others

How Does Artificial Intelligence Contribute To Improve Refractory Material Market ?

- Predictive Maintenance & Failure Analysis: AI-powered sensors monitor refractory wear and thermal stress in real-time, enabling proactive maintenance and reducing downtime.

- Process Optimization & Efficiency Enhancement: Machine learning algorithms optimize furnace and kiln operations, improving energy efficiency and extending refractory lifespan.

- Material Design & Development: AI accelerates the discovery of advanced refractory formulations with improved heat resistance, durability, and sustainability.

- Quality Control & Defect Detection: AI-driven imaging and inspection systems detect defects or inconsistencies in refractory materials, ensuring higher product reliability.

- Supply Chain & Inventory Management: AI(Artificial Intelligence) analyzes demand trends and optimizes raw material procurement and logistics, reducing costs and preventing supply shortages.

Regional Analysis

During the forecast period (2023-2032), the refractory material market in the Asia-Pacific region is expected to experience significant growth. However, in 2023, the Asia-Pacific region accounts for 82.3% of the market share, majorly because of the rising demand for iron & steel across various sectors like construction, industry, automotive, & more.

This rise in demand has pushed iron and steel manufacturers to expand their production capacities, where refractory materials are important for maintaining stable temperatures. Especially, in China, the cement manufacturing sector is rapidly expanding, compelling refractory material producers to develop high-quality products tailored for high-temperature applications in furnaces, kilns, incinerators, & similar settings.

Moreover, in North America, market expansion is anticipated due to rising requirements from several sectors within the region, notably the iron & steel as well as glass industries. Europe's market, on the other hand, is poised for sustained growth, driven by the increasing steel and glass demands from the automotive manufacturers operating within the region.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The Global Market for Refractory Materials is competitive, with many companies trying to be the best. They use different strategies like working together or creating new products to stay ahead. These companies also focus on making their products eco-friendly to meet the demand for environmentally friendly items.

Changes in technology, rules, and what people like affect this market. The companies that can adapt to these changes and offer good quality materials do well. Industries like steel, cement, glass, and automotive need these materials, so companies work hard to meet their needs and stay competitive in the market.

Some of the prominent players in the Global Refractory Material Market are:

- Imerys

- Saint-Gobain

- RHI Magnestia

- KAEFER SE & Co. KG

- Alsey Refractories Co.

- Magnezit Group

- Harbison Walker International

- Dalmia Bharat Refractory

- Morgan Advanced Materials

- Lanexis

- Vitcas

- Other Key Players

Recent Developments

- In November 2024, RHI Magnesita launched 4PRO, an innovative contract model for refractory solutions, emphasizing sustainability and technology in cement, steel, and glass sectors.

- In November 2024, Vesuvius commissioned new alumina-silica and monolithic refractory plants in Visakhapatnam, India, expanding local production capacity for the steel industry.

- In October 2024, Calderys invested in the largest greenfield refractory plant in Odisha, India; the 40-acre facility will use sustainable technology and create 350 jobs by 2026.

- In November 2024, RHI Magnesita installed advanced “Raptor” automated sorting equipment for recycling refractories at its Mitterdorf facility, enhancing sustainability efforts.

- In January 2025, RHI Magnesita completed the acquisition of Resco Group, more than doubling its U.S. business and strengthening its position in alumina-based refractories.

- In March 2024, RHI Magnesita agreed to acquire Resco Group in a transaction valued up to USD 430 million, targeting strategic expansion and supply chain synergies.

Report Details

| Report Characteristics |

| Market Size (2023) |

USD 30 Bn |

| Forecast Value (2032) |

USD 46.1 Bn |

| CAGR (2023–2032) |

4.9% |

| Historical Data |

2017 – 2022 |

| Forecast Data |

2023 – 2032 |

| Base Year |

2022 |

| Estimate Year |

2023 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Form (Shaped and Unshaped), By Product (Clay and Non-Clay), By Alkalinity (Basic and Acidic & Neutral), and By End-User (Iron & Steel, Non-Ferrous Metals, Glass, Cement, and Others). |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA |

| Prominent Players |

Imerys, Saint-Gobain, RHI Magnestia, KAEFER SE & Co. KG, Alsey Refractories Co., Magnezit Group, Harbison Walker International, Dalmia Bharat Refractory, Morgan Advanced Materials, Lanexis, Vitcas, and Other Key Players. |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |