Market Overview

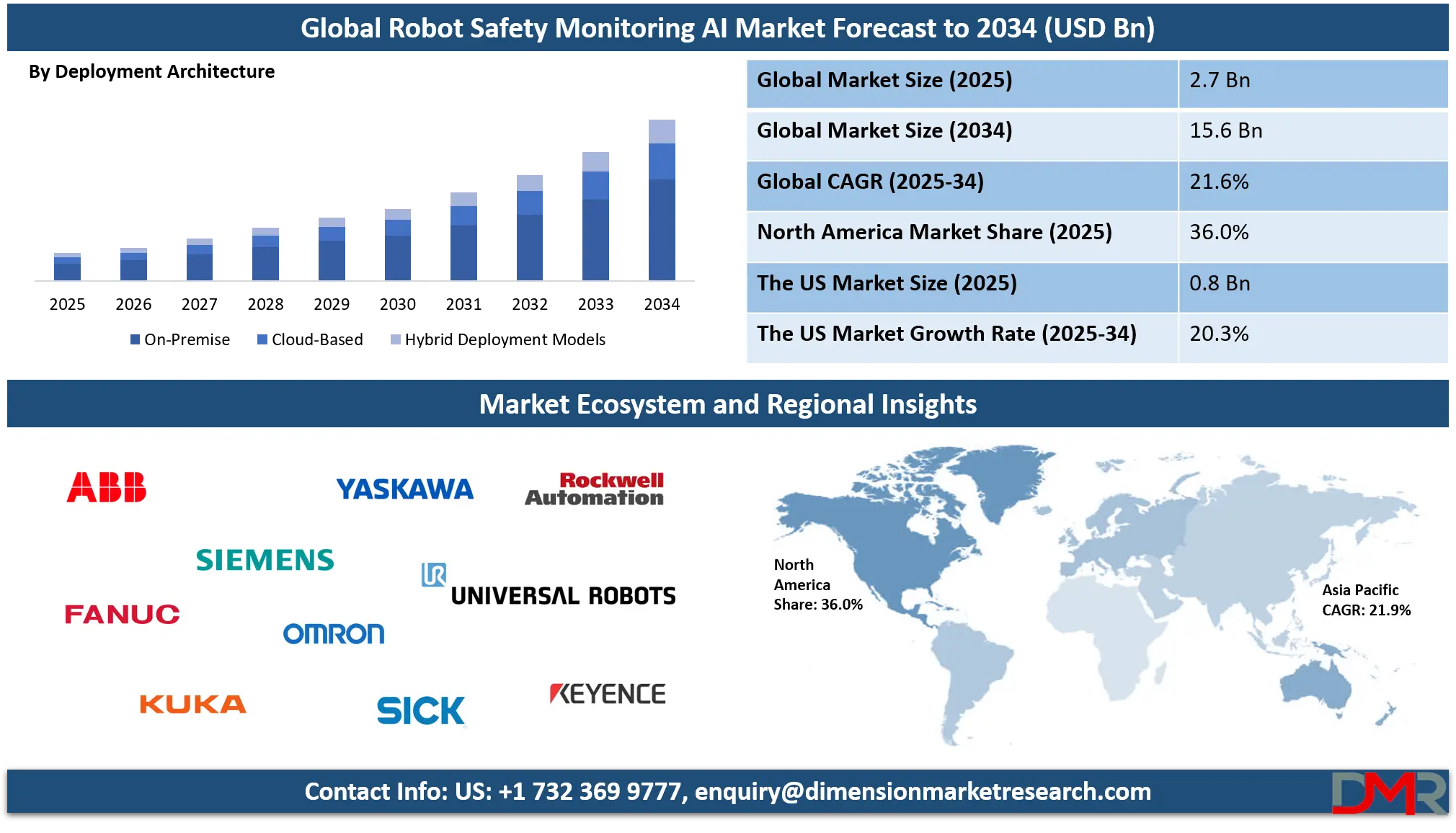

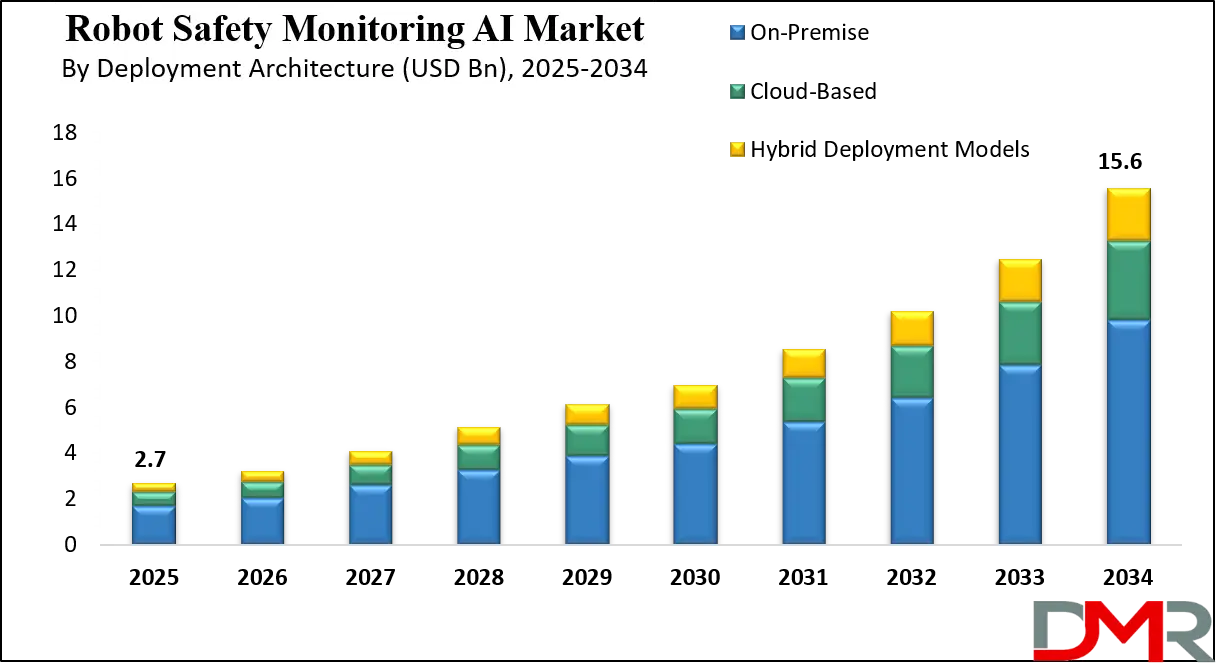

The Global Robot Safety Monitoring AI Market was valued at USD 2.7 billion in 2025 and is projected to reach USD 15.6 billion by 2034, growing at a CAGR of 21.6%, driven by rising industrial automation, increased deployment of collaborative robots, advancements in artificial intelligence based safety systems, and growing demand for real time robot monitoring and predictive safety analytics across manufacturing, logistics, and healthcare sectors.

Robot Safety Monitoring AI refers to the application of artificial intelligence technologies to continuously observe, analyze, and control robot operations in order to prevent accidents, reduce human risk, and ensure safe interaction between robots and their surroundings. It uses intelligent vision systems, sensor data processing, machine learning models, and behavioral analytics to detect unsafe movements, human proximity, abnormal robot behavior, and potential equipment failures before incidents occur. By enabling automated decision making and instant response actions such as speed reduction or system shutdown, Robot Safety Monitoring AI enhances workplace safety, improves operational reliability, and supports compliance with industrial safety regulations across robotic environments.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

The global Robot Safety Monitoring AI Market represents the growing commercial ecosystem focused on delivering intelligent safety solutions for robotic systems used across industrial, commercial, and service environments worldwide. The market is driven by rapid automation adoption, rising deployment of collaborative robots, and increasing emphasis on occupational safety in manufacturing and logistics facilities. Advancements in computer vision, deep learning, and sensor fusion are enabling more accurate risk detection and predictive safety capabilities, making AI based safety monitoring an essential component of modern robotic systems across industries such as automotive, electronics, healthcare, and warehousing.

In addition, the global Robot Safety Monitoring AI Market is shaped by strict regulatory frameworks, rising investments in smart factories, and the need for continuous monitoring in dynamic human robot interaction settings. Organizations are increasingly integrating intelligent safety platforms to reduce downtime, prevent costly accidents, and improve productivity while maintaining compliance with international safety standards. The market continues to expand as enterprises adopt autonomous mobile robots, service robots, and advanced industrial robots, creating sustained demand for scalable, adaptive, and data driven robot safety monitoring solutions across both developed and emerging economies.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

The US Robot Safety Monitoring AI Market

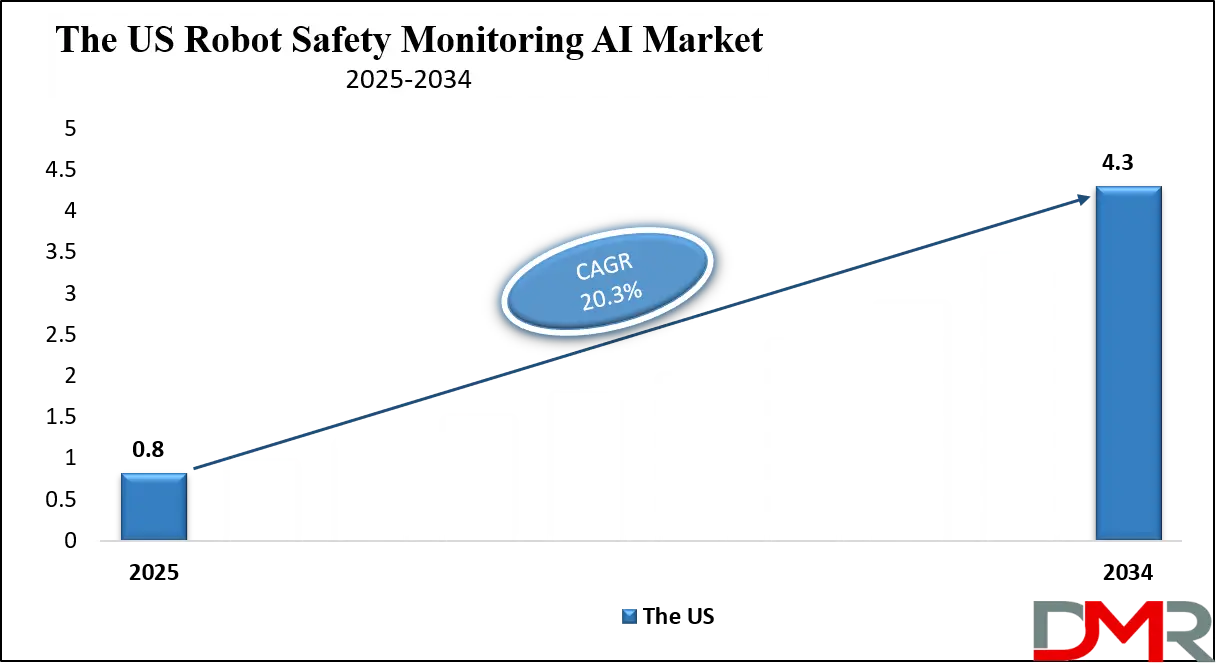

The U.S. Robot Safety Monitoring AI Market size was valued at USD 0.8 billion in 2025. It is further expected to witness subsequent growth in the upcoming period, holding USD 4.3 billion in 2034 at a CAGR of 20.3%.

The US Robot Safety Monitoring AI Market is experiencing strong growth due to the rapid adoption of advanced automation technologies across manufacturing, automotive, and logistics industries. Increasing deployment of industrial robots and collaborative robots has intensified the need for intelligent safety monitoring systems that can ensure safe human robot interaction. The presence of advanced manufacturing facilities, early adoption of artificial intelligence, and strong investments in smart factory initiatives are driving demand for real time robot safety analytics, machine vision based monitoring, and predictive risk detection solutions across large scale industrial environments.

In addition, strict workplace safety regulations and high awareness of occupational safety standards are encouraging US enterprises to integrate AI driven robot safety monitoring platforms. Growing use of autonomous mobile robots in warehouses and fulfillment centers is further increasing the need for continuous safety surveillance and adaptive response systems. Technological advancements in computer vision, edge AI, and sensor fusion are enabling more accurate hazard detection and faster response times, supporting widespread adoption of intelligent robot safety solutions across diverse industrial and commercial applications.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Europe Robot Safety Monitoring AI Market

The Europe Robot Safety Monitoring AI Market was valued approximately at USD 432 million in 2025, reflecting significant growth driven by increasing industrial automation and adoption of intelligent safety solutions across manufacturing, automotive, and logistics sectors. The presence of technologically advanced factories, strict workplace safety regulations, and growing demand for collaborative and autonomous robots are contributing to the market expansion. Companies in the region are investing in AI based real‑time hazard detection, predictive analytics, and machine vision systems to enhance operational safety and comply with European safety standards.

The market in Europe is expected to grow at a CAGR of 16.7% during the forecast period, supported by ongoing digitalization initiatives, smart factory deployments, and rising awareness of occupational safety. The adoption of AI driven robot safety monitoring solutions enables businesses to reduce downtime, prevent accidents, and optimize productivity while maintaining compliance with regulatory requirements. Additionally, technological advancements in edge AI, sensor fusion, and cloud based monitoring platforms are driving further investment and innovation, positioning Europe as a key growth region within the global Robot Safety Monitoring AI market.

Japan Robot Safety Monitoring AI Market

The Japan Robot Safety Monitoring AI Market was valued at USD 270 million in 2025, driven by the country’s advanced industrial base, high adoption of robotics in manufacturing, and stringent safety standards. Japanese industries, particularly automotive, electronics, and precision manufacturing, are increasingly deploying AI enabled safety monitoring systems to ensure safe human robot interaction, prevent accidents, and enhance operational efficiency. The market is supported by investments in collaborative robots and autonomous mobile robots, where real‑time hazard detection and predictive safety analytics are critical for maintaining workplace safety.

The market in Japan is expected to grow at a CAGR of 17.6% during the forecast period, fueled by continuous innovation in AI technologies, machine vision, and sensor integration. Companies are adopting intelligent safety platforms that provide predictive maintenance, performance monitoring, and regulatory compliance capabilities. Rising demand for smart factories, automation of production lines, and integration of AI‑driven robotics in logistics and service sectors further contribute to market expansion, making Japan one of the key growth regions within the global Robot Safety Monitoring AI market.

Global Robot Safety Monitoring AI Market: Key Takeaways

- Rapid Market Expansion: The global Robot Safety Monitoring AI market is growing swiftly, driven by increasing industrial automation, AI adoption, and the deployment of collaborative and autonomous robots across manufacturing, logistics, and healthcare sectors.

- Technology-Driven Safety Solutions: AI powered machine vision, sensor fusion, and predictive analytics are transforming robot safety from reactive monitoring to intelligent, real-time risk prevention, enhancing workplace safety and operational efficiency.

- Regional Growth Dynamics: North America leads in revenue share due to early automation adoption, while Asia Pacific and Japan are high-growth regions fueled by smart factories, industrial robotics deployment, and regulatory emphasis on workplace safety.

- Industrial and Collaborative Robot Focus: Industrial robots dominate in adoption due to high-speed production needs, whereas collaborative robots are expanding rapidly, creating demand for adaptive AI safety systems in human-robot interaction environments.

- Adoption Drivers and Challenges: Growth is supported by strict safety regulations, digitalization, and edge AI integration, but high implementation costs and integration complexity with legacy systems remain key challenges for widespread deployment.

Global Robot Safety Monitoring AI Market: Use Cases

- Industrial Manufacturing Safety: Robot Safety Monitoring AI is used to monitor industrial robots on factory floors by detecting unsafe movements, human presence, and collision risks in real time. AI based vision systems and sensors enable automatic speed control and emergency shutdowns, improving workplace safety and regulatory compliance.

- Collaborative Robot Interaction: In collaborative robot environments, safety monitoring AI analyzes human motion, force limits, and robot behavior to prevent accidents. These systems support safe human robot interaction while enabling flexible automation in assembly and packaging operations.

- Autonomous Mobile Robot Operations: Robot Safety Monitoring AI ensures safe movement of autonomous mobile robots in warehouses by monitoring obstacles, pedestrian activity, and traffic conditions. Real time analytics help reduce collisions and operational disruptions.

- Healthcare and Medical Robotics Safety: In healthcare settings, robot safety monitoring AI supports safe operation of surgical and service robots by detecting abnormal behavior and potential risks. This use case improves patient safety and system reliability in clinical environments.

Impact of Artificial Intelligence on the global Robot Safety Monitoring AI market

The impact of artificial intelligence on the global Robot Safety Monitoring AI market has been transformative, elevating safety systems from basic rule-based controls to intelligent, adaptive risk prevention platforms. AI technologies such as machine learning, deep learning, and computer vision enable real-time interpretation of complex sensory data from cameras, lidar, and proximity sensors to detect unsafe conditions before they result in accidents. This shift has significantly increased the accuracy and responsiveness of safety monitoring solutions, allowing systems to learn normal behavior patterns, identify anomalies, and trigger automated interventions such as speed reduction, path adjustment, or emergency shutdowns. AI also supports predictive analytics that anticipates potential failures, reducing downtime and maintenance costs while improving overall operational efficiency.

Furthermore, artificial intelligence has expanded the applicability of robot safety monitoring beyond traditional industrial automation to collaborative robots, autonomous mobile robots, and service robotics across healthcare, logistics, and consumer sectors. By enabling adaptive safety strategies that evolve with changing environments and task requirements, AI has accelerated market adoption, encouraged new product innovations, and strengthened compliance with global safety standards. As a result, AI is a key driver of market growth, differentiating advanced safety solutions, enhancing human-robot interaction safety, and supporting scalable deployments in smart factories and automated facilities worldwide.

Global Robot Safety Monitoring AI Market: Stats & Facts

International Federation of Robotics (Global Industry Organization)

- Worldwide operational industrial robots reached 4,281,585 units in 2023, a 10% increase year‑on‑year, highlighting rapid automation growth.

- 541,302 industrial robots were installed globally in 2023, marking the third consecutive year above half a million annual installations.

- In 2023, 70% of newly deployed robots were installed in Asia, 17% in Europe, and 10% in the Americas, showing regional distribution of automation.

- Japan accounted for 10.2% of the global operational stock of industrial robots in 2023, illustrating its major role in global robotics deployment.

- Global robot density (robots per 10,000 manufacturing employees) increased from 151 to 162, indicating deeper penetration of automation in manufacturing sectors.

- Sales of professional service robots increased by approximately 30% worldwide with over 205,000 units registered in 2023, emphasizing growth in non‑industrial robotic applications.

- Asia accounted for 74% of new industrial robot deployments in 2024, compared with 16% in Europe and 9% in the Americas.

- 542,000 industrial robots were installed worldwide in 2024, more than double the number from ten years earlier, reflecting long‑term adoption trends.

- Robot installations in the Americas exceeded 50,000 units in 2023 for the fourth consecutive year.

- The United States accounted for 68% of robot installations in the Americas region in 2023.

- India saw industrial robot installations of 8,510 units in 2023, a 59% increase from the previous year, ranking it seventh worldwide.

- India’s operational stock of industrial robots nearly doubled since 2018, reflecting a ~14% average annual growth since that year.

Global Robot Safety Monitoring AI Market: Market Dynamics

Global Robot Safety Monitoring AI Market: Driving Factors

Rapid Industrial Automation Adoption

The increasing deployment of robotics across manufacturing, automotive, and electronics industries is a key driver for the Robot Safety Monitoring AI market. As companies implement automated production lines and autonomous systems, the need for intelligent safety monitoring that can detect hazards, track human movement, and prevent collisions has grown significantly. The integration of AI enabled sensor systems and machine vision based monitoring supports real time risk identification and enhances operational safety in complex automated environments.

Rising Emphasis on Workplace Safety Regulations

Stringent workplace safety standards and regulatory compliance requirements are accelerating demand for advanced safety solutions. Government and industry safety regulations mandate continuous monitoring of robot operations to protect human workers from accidents and injuries. AI powered safety systems that provide predictive analytics, automated incident reporting, and compliance tracking help organizations meet regulatory benchmarks and minimize legal liabilities, driving broader adoption of intelligent robot safety technologies globally.

Global Robot Safety Monitoring AI Market: Restraints

High Implementation Costs

The upfront investment required for AI driven safety monitoring platforms, including hardware, software, and integration services, can be a significant barrier for small and medium sized enterprises. Costs associated with machine vision sensors, edge computing devices, and advanced analytics software may limit deployment in cost sensitive operations. This financial burden can slow market penetration, especially in regions with lower automation budgets.

Integration Complexity with Legacy Systems

Deploying Robot Safety Monitoring AI solutions in existing facilities often involves complex integration with legacy automation equipment and control systems. Compatibility challenges, data interoperability issues, and the need for custom configuration can increase deployment time and require specialized technical expertise. These integration hurdles may deter organizations from upgrading to intelligent safety monitoring platforms despite their potential benefits.

Global Robot Safety Monitoring AI Market: Opportunities

Expansion in Collaborative Robot Ecosystems

The rising use of collaborative robots in small scale manufacturing, assembly, and logistics presents a significant growth opportunity. These robots operate in close proximity to human workers, creating demand for AI based safety monitoring that can adapt to dynamic environments and unpredictable human behavior. Solutions that combine deep learning based motion analysis with adaptive response mechanisms will gain traction as collaborative robot adoption increases.

Growth in Edge AI and Predictive Safety Analytics

Advancements in edge computing and predictive analytics are creating opportunities for more efficient and responsive safety monitoring. Edge AI enables low latency decision making by processing sensor data locally, while predictive analytics can identify failure patterns before incidents occur. These technologies can reduce downtime, improve throughput, and enable proactive safety strategies, unlocking new value for enterprises seeking real time insights and continuous performance optimization.

Global Robot Safety Monitoring AI Market: Trends

Integration of Machine Vision and Sensor Fusion

A prominent market trend is the convergence of machine vision technologies with multi sensor fusion to deliver more accurate safety monitoring. Combining visual data with inputs from lidar, ultrasonic sensors, and force feedback devices enables a holistic understanding of robot environments. This trend enhances hazard detection capabilities and supports more intelligent, context aware safety responses in complex operational settings.

Adoption of Cloud Based Safety Platform

sCloud based solutions are emerging as a trend for centralized safety monitoring across multiple facilities and distributed robot fleets. These platforms offer scalable analytics, remote performance dashboards, and centralized update management, enabling organizations to monitor safety metrics in real time from any location. Cloud connectivity also supports long term data storage and advanced AI model training, contributing to continuous improvement in safety monitoring performance.

Global Robot Safety Monitoring AI Market: Research Scope and Analysis

By Solution Type Analysis

Hardware-Based Safety Monitoring AI is anticipated to dominate the solution type segment, capturing 52.0% of the total market share in 2025, primarily due to its critical role in enabling real time safety detection at the physical level of robotic operations. These solutions include vision cameras, proximity sensors, force and torque sensors, and edge AI controllers that directly interact with robots and their surrounding environments. Industries with high robot density such as manufacturing, automotive, and logistics rely heavily on hardware driven safety systems to ensure low latency responses, immediate hazard detection, and compliance with strict safety regulations. The widespread installation of safety hardware in existing and new robotic cells, combined with the need for reliable and continuous monitoring, strongly supports the dominance of this segment.

In contrast, Software-Based Safety Intelligence plays a complementary but increasingly important role within the same market segment by transforming raw sensor data into actionable safety insights. AI driven software platforms use machine learning, computer vision algorithms, and predictive analytics to identify unsafe behavior patterns, anticipate potential failures, and optimize safety responses across robotic systems. These solutions enable centralized monitoring, safety performance analysis, and regulatory reporting while supporting scalable deployment across multiple sites. Growing adoption of collaborative robots, autonomous mobile robots, and smart factory initiatives is accelerating demand for intelligent safety software, positioning this segment for strong growth alongside hardware based safety monitoring AI.

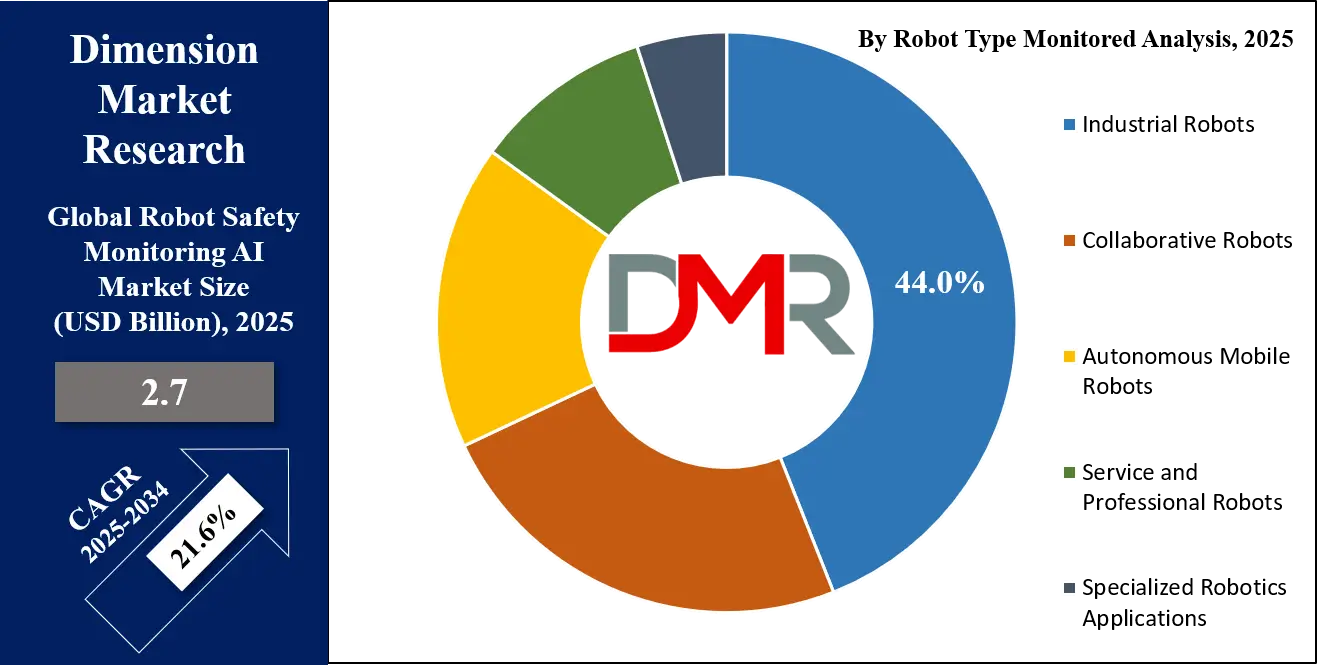

By Robot Type Monitored Analysis

Industrial Robots are anticipated to dominate the robot type monitored segment, capturing 44.0% of the total market share in 2025, driven by their extensive deployment across large scale manufacturing, automotive production, and heavy industrial operations. These robots perform high speed, high precision tasks in environments where safety risks are significant, requiring continuous monitoring of motion, speed, force, and workspace conditions. The high density of industrial robots on factory floors and strict compliance requirements for worker safety have led to widespread adoption of AI enabled safety monitoring systems that can detect collisions, unsafe movements, and equipment anomalies in real time, reinforcing the strong market position of this segment.

Collaborative Robots represent a fast growing segment within the same market, as they are specifically designed to operate in close proximity to human workers. Unlike traditional industrial robots, cobots require advanced safety monitoring AI to dynamically adjust speed, force, and behavior based on human presence and task complexity. AI driven vision systems, behavior recognition algorithms, and predictive safety analytics enable safe and flexible human robot interaction. Rising adoption of collaborative robots in electronics assembly, packaging, and small scale manufacturing is accelerating demand for intelligent safety monitoring solutions, contributing to the expanding importance of this segment.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

By Deployment Architecture Analysis

On-premise deployments are anticipated to dominate the deployment architecture segment, capturing 63.0% of the total market share in 2025, largely due to the need for real time decision making, low latency response, and high data security in safety critical robotic environments. Manufacturing plants, automotive facilities, and logistics hubs prefer on-premise robot safety monitoring AI systems because they allow direct processing of sensor and vision data within the facility, ensuring immediate hazard detection and automated emergency actions. Additionally, on-premise deployments support compliance with strict industrial safety standards and data governance requirements, making them the preferred choice for large scale and high risk operations.

Cloud based deployment models are gaining steady traction within the same market segment as organizations seek centralized visibility and advanced analytics across distributed robotic systems. Cloud based robot safety monitoring AI platforms enable remote monitoring, performance benchmarking, and continuous improvement through large scale data aggregation and machine learning model updates. These solutions are particularly attractive for enterprises operating multiple facilities or deploying autonomous mobile robots across wide areas. While latency concerns limit full reliance on cloud systems for critical safety actions, hybrid and cloud supported architectures continue to expand due to their scalability, flexibility, and cost efficiency benefits.

By Safety Functionality Analysis

Real-Time Hazard Detection is anticipated to dominate the safety functionality segment, capturing 38.0% of the total market share in 2025, as it provides immediate monitoring and response to potential safety threats in robotic environments. This functionality uses AI enabled vision systems, proximity sensors, and motion tracking to detect unsafe conditions, human presence, or abnormal robot behavior instantly. Industrial floors, warehouses, and collaborative workspaces rely on real-time hazard detection to prevent accidents, reduce downtime, and ensure compliance with safety regulations, making it a critical component of robot safety monitoring AI solutions.

Predictive and Preventive Safety Analytics, while slightly smaller in market share, plays a crucial role in enhancing operational efficiency by forecasting potential risks before they occur. Using machine learning algorithms and historical performance data, these AI systems identify patterns that indicate possible robot malfunctions, unsafe workflows, or collision risks. By providing early warnings and actionable insights, predictive analytics enable organizations to schedule maintenance, adjust robot behavior, and implement preventive measures, minimizing downtime and improving overall safety and productivity across manufacturing, logistics, and healthcare robotics applications.

By End-Use Industry Analysis

Manufacturing industries are anticipated to dominate the end-use industry segment, capturing 39.0% of the total market share in 2025, due to the widespread deployment of industrial robots and automation systems in production facilities. Robot safety monitoring AI is critical in these environments to ensure safe operation of heavy machinery, high-speed assembly lines, and material handling equipment. By providing real-time hazard detection, motion tracking, and emergency intervention, these AI systems help prevent accidents, reduce downtime, and maintain compliance with stringent workplace safety regulations, making them essential for modern manufacturing operations.

Automotive manufacturing represents a significant segment within the same market, driven by the extensive use of industrial and collaborative robots in vehicle assembly, welding, painting, and component production. AI powered safety monitoring solutions in automotive plants enable continuous supervision of robot movements, human worker interactions, and operational anomalies. Predictive analytics and real-time monitoring allow manufacturers to prevent collisions, optimize workflow safety, and maintain production efficiency. The high degree of automation, strict quality standards, and safety compliance requirements make automotive manufacturing a key driver for the adoption of robot safety monitoring AI.

The Robot Safety Monitoring AI Market Report is segmented on the basis of the following:

By Solution Type

- Hardware-Based Safety Monitoring AI

- Vision cameras and imaging devices

- Proximity and force sensors

- Edge AI processors and safety controllers

- Emergency stop and safety interlock systems

- Software-Based Safety Intelligence

- Real-time risk detection platforms

- Predictive safety analytics solutions

- Motion and behavior recognition AI

- Safety compliance and reporting software

- Services and System Integration

- Safety system integration services

- AI model training and customization

- Maintenance and performance optimization

- Regulatory compliance consulting

By Robot Type Monitored

- Industrial Robots

- Welding robots

- Assembly line robots

- Material handling robots

- Packaging robots

- Collaborative Robots

- Assembly cobots

- Pick-and-place cobots

- Inspection cobots

- Autonomous Mobile Robots

- Warehouse transport robots

- Factory logistics robots

- Hospital transport robots

- Service and Professional Robots

- Medical and surgical robots

- Cleaning and maintenance robots

- Hospitality service robots

- Specialized Robotics Applications

- Inspection robots

- Defense and security robots

- Research robots

By Deployment Architecture

- On-Premises

- Cloud-Based

- Hybrid Deployment Models

By Safety Functionality

- Real-Time Hazard Detection

- Human presence detection

- Collision and intrusion detection

- Unsafe motion identification

- Predictive and Preventive Safety Analytics

- Behavior anomaly prediction

- Component failure risk analysis

- Unsafe workflow pattern detection

- Compliance and Regulatory Monitoring

- Workplace safety compliance tracking

- Incident documentation and reporting

- Audit and certification support

- Emergency Response Automation

- Automatic robot shutdown

- Speed and force adjustment mechanisms

- Emergency alert and escalation systems

By End-Use Industry

- Manufacturing Industries

- Automotive Manufacturing

- Logistics and Warehousing

- Healthcare and Medical Facilities

- Aerospace and Defense Manufacturing

- Other Industries

Global Robot Safety Monitoring AI Market: Regional Analysis

Region with the Largest Revenue Share

North America is anticipated to lead the global Robot Safety Monitoring AI Market landscape, accounting for 36.0% of total market revenue in 2025, driven by the early adoption of advanced industrial automation, widespread deployment of collaborative and autonomous robots, and strong emphasis on workplace safety compliance. The presence of technologically advanced manufacturing facilities, robust investment in smart factory initiatives, and growing use of AI enabled safety monitoring solutions across automotive, electronics, and logistics sectors contribute to the region’s market dominance. High awareness of occupational safety standards further accelerates the adoption of intelligent robot safety systems.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Region with significant growth

Asia Pacific is expected to witness significant growth in the Robot Safety Monitoring AI Market due to rapid industrialization, increasing adoption of automation in manufacturing and logistics, and rising deployment of collaborative and autonomous robots across emerging economies such as China, Japan, and India. Growing investments in smart factories, expanding e-commerce and warehousing operations, and a focus on improving workplace safety are driving demand for AI based real-time monitoring and predictive safety solutions. Technological advancements in machine vision, edge AI, and sensor fusion further support accelerated market expansion in the region.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Global Robot Safety Monitoring AI Market: Competitive Landscape

The competitive landscape of the global Robot Safety Monitoring AI market is characterized by intense innovation, strategic partnerships, and continuous adoption of advanced technologies to develop more accurate, reliable, and scalable safety solutions. Companies are investing in research and development to enhance real‑time hazard detection, predictive analytics, and machine vision capabilities, while also focusing on software integration and edge AI processing to meet diverse industry requirements.

The market is marked by a focus on customizable offerings, ecosystem collaborations, and expansion into new geographic regions to address growing demand from manufacturing, logistics, and healthcare sectors. Technological differentiation, service support, and compliance with evolving safety standards play key roles in shaping competitive positioning.

Some of the prominent players in the global Robot Safety Monitoring AI market are:

- ABB Ltd.

- Siemens AG

- FANUC Corporation

- KUKA AG

- Yaskawa Electric Corporation

- Omron Corporation

- Rockwell Automation, Inc.

- Universal Robots

- SICK AG

- Keyence Corporation

- Honeywell International Inc.

- Schneider Electric SE

- Mitsubishi Electric Corporation

- Pilz GmbH & Co. KG

- Cognex Corporation

- Banner Engineering Corp.

- DENSO Corporation

- Epson Robots

- Bosch Rexroth AG

- Teradyne Inc.

- Other Key Players

Global Robot Safety Monitoring AI Market: Recent Developments

- January 2026: A leading autonomous driving and AI hardware company agreed to acquire a specialized humanoid robotics startup, expanding its footprint in AI‑enabled physical systems and signaling strategic growth in robotics platforms that can support advanced safety and monitoring functions in real‑world environments.

- January 2026: An Estonian robotics startup secured €3.7 million in pre‑seed funding to advance development and commercialization of a new autonomous security robot platform, moving from research into early production to strengthen safety and monitoring applications.

- October 2025: A robotics technology provider unveiled an advanced AI powered robot security inspection solution aimed at enhancing autonomous monitoring and real‑time hazard detection across industrial and smart infrastructure environments, marking a significant product launch that integrates physical AI, advanced perception, and automated patrol capabilities.

- October 2025: An industrial robotics maker introduced a next generation AI integrated robot controller designed to enhance real‑time safety performance and intelligent control in industrial automation systems, improving responsiveness and operator protection in manufacturing settings.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 13.0 Bn |

| Forecast Value (2034) |

USD 25.7 Bn |

| CAGR (2025–2034) |

8.3% |

| The US Market Size (2025) |

USD 4.2 Bn |

| Historical Data |

2019 – 2024 |

| Forecast Data |

2026 – 2034 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors, etc. |

| Segments Covered |

By Component (Hardware, Software, Services), By ACaaS Deployment (Hosted, Managed, Hybrid), By Authentication Method (Single-Factor, Multi-Factor, Mobile Credential/Bluetooth LE), By Connectivity Technology (RFID/NFC, Smart Cards, Bluetooth Low Energy, Ultra-Wideband), By Technology (Authentication Systems, Detection Systems, Alarm Panels, Communication Devices, Perimeter Security Systems), By End-Use Vertical (Commercial Buildings, Industrial & Manufacturing, Government & Public Sector, Military & Defense, Transport & Logistics, Healthcare, Residential & Smart Homes, Education & Research, Energy & Utilities, Hospitality & Entertainment, Retail & Customer-Facing, Financial Institutions, Others) |

| Regional Coverage |

North America – US, Canada; Europe – Germany, UK, France, Russia, Spain, Italy, Benelux, Nordic, Rest of Europe; Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, Rest of MEA |

| Prominent Players |

ASSA ABLOY, dormakaba Group, Johnson Controls, Allegion plc, Honeywell International, Identiv Inc., Nedap N.V., Suprema Inc., Bosch Security Systems, Thales Group, AMAG Technology, Axis Communications, NEC Corporation, Gallagher Group, Brivo Systems, SALTO Systems, Genetec Inc., HID Global, Siemens, Cansec Systems., and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days, and 5 analysts working days respectively. |

Frequently Asked Questions

How big is the global Robot Safety Monitoring AI market?

▾ The global Robot Safety Monitoring AI market size was valued at USD 2.7 billion in 2025 and is expected to reach USD 15.6 billion by the end of 2034.

What is the size of the US Robot Safety Monitoring AI market?

▾ The US Robot Safety Monitoring AI market was valued at USD 0.8 billion in 2025. It is expected to witness subsequent growth in the upcoming period as it holds USD 4.3 billion in 2034 at a CAGR of 20.3%.

Which region accounted for the largest global Robot Safety Monitoring AI market?

▾ North America is expected to have the largest market share in the global Robot Safety Monitoring AI market, with a share of about 36.0% in 2025.

Who are the key players in the global Robot Safety Monitoring AI market?

▾ Some of the major key players in the global Robot Safety Monitoring AI market are ABB Ltd., Siemens AG, FANUC Corporation, KUKA AG, Yaskawa Electric Corporation, Omron Corporation, Rockwell Automation, Inc., Universal Robots, SICK AG, Keyence Corporation, Honeywell International Inc., Schneider Electric SE, Mitsubishi Electric Corporation, Pilz GmbH & Co. KG, and Others.