Market Overview

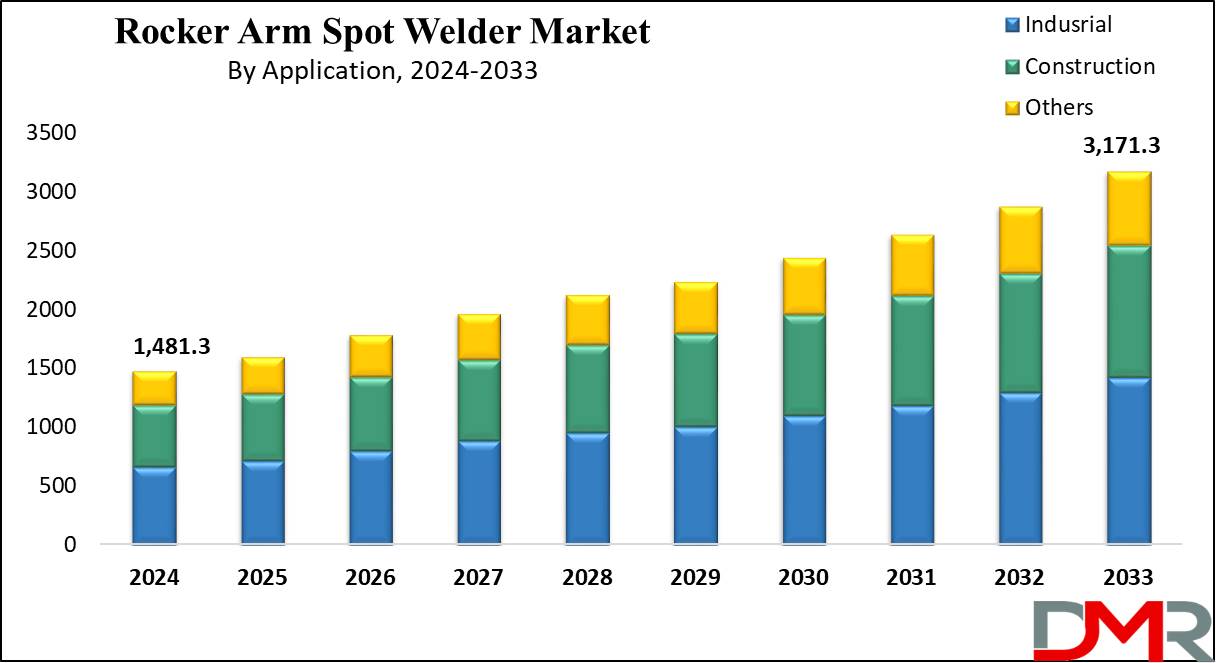

The Global

Rocker Arm Spot Welder Market size is expected to reach a value of

USD 1,481.3 million in 2024, and it is further anticipated to reach a market value of

USD 3,171.3 million by 2033 at a CAGR of

8.8%.

It finds wide applications in industries such as automotive, aerospace, electronics, and metal fabrication, due to which the global rocker arm spot welder market has grown significantly. Rocker arm spot welders belong to a class of precision machines employed in diverse spot welding operations on assembly lines where consistent high-quality welds are crucial. The size of the market has become remarkably valuable in recent years and is projected to witness robust growth driven by welding accuracy and production efficiency as prime concerns for industries. These machines also offer controlled pressure and positioning, enabling high weld strength and quality, hence increasing demand in industries that have high demands on quality control.

This growth in the market is also propelled by increasing automation and technologically advanced welding system demands. Major players operating in the rocker arm welder market, such as Taylor-Winfield, TJ Snow, and Mechelonic Welders, focus on R&D to come up with energy-efficient models with superior levels of automation. The market is further driven due to the growing trend of producing electric vehicles mainly in North America and Europe, as manufacturers seek appropriate welding solutions to fabricate lightweight and strong vehicle components.

The rocker arm spot welder market would mark significant growth in CAGR, and estimates have shown that taking into note the redemption of precision welding, the market size is bound to reach significant amounts by 2030. Further improvements in welding technology, which are already underway, signal the continued growth of the rocker arm spot welder market well in the future.

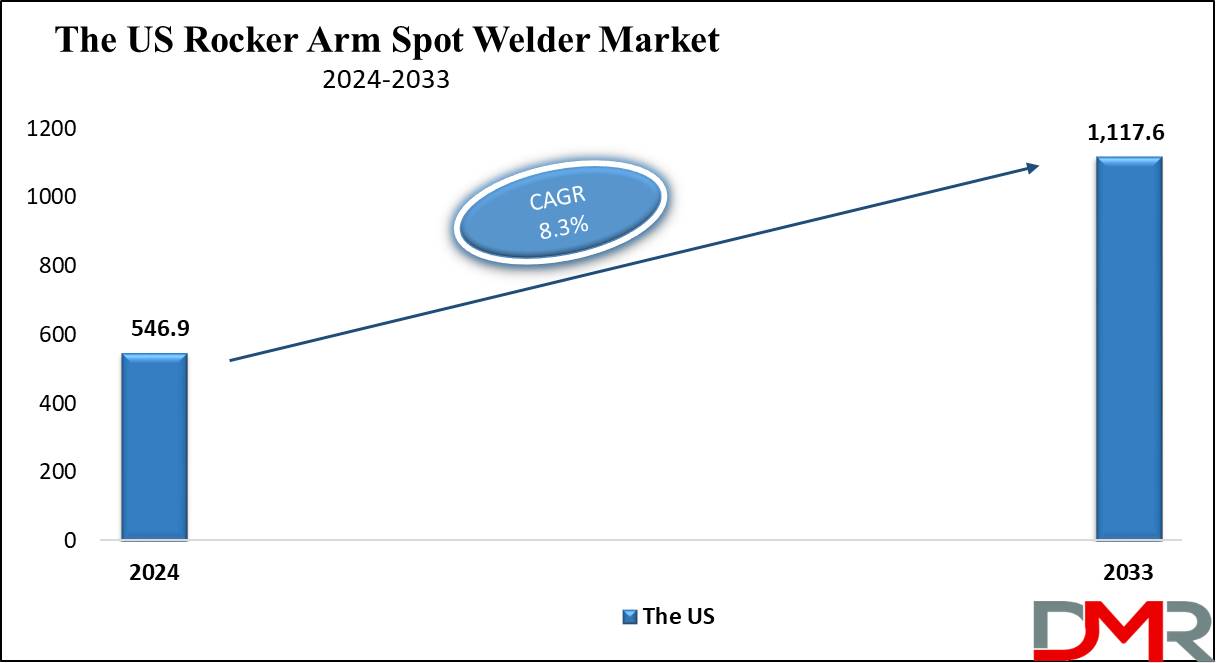

The US Rocker Arm Spot Welder Market

The US Rocker Arm Spot Welder Market is projected to be valued at USD 546.9 million in 2024. It is expected to witness subsequent growth in the upcoming period as it holds USD 1,117.6 million in 2033 at a CAGR of 8.3%. The U.S. rocker arm spot welder market is witnessing a robust growth trajectory, largely due to increased demand from the automotive and aerospace industries.

The U.S. market has become a hub for advanced welding technology adoption, emphasizing efficiency, precision, and automation. One significant trend driving this market is the growing emphasis on electric vehicle (EV) manufacturing. As automakers transition towards EVs, the need for lightweight, durable materials grows, boosting demand for spot welding solutions like rocker arm spot welders that offer high-quality welds for lighter metals.

Developments in automation and Industry 4.0 initiatives are further shaping the market, with manufacturers investing in smart welding systems to optimize production efficiency. Companies such as TJ Snow and Taylor-Winfield are focusing on enhancing their rocker arm welders with features like advanced control systems and energy-efficient designs, aligning with sustainability goals across various industries.

Additionally, the U.S. market is characterized by high-quality standards and stringent regulations, further driving the demand for reliable and precision-oriented welding solutions. As industry players continue to innovate, the U.S. rocker arm spot welder market is set for steady growth, driven by ongoing industrial advancements and increasing reliance on automated welding technologies.

Key Takeaways

- Global Value: The Global Rocker Arm Spot Welder Market size is estimated to have a value of USD 1,481.3 million in 2024 and is expected to reach USD 3,171.3 million by the end of 2033.

- The US Market Share: The US Rocker Arm Spot Welder Market is projected to be valued at USD 1,117.6 million in 2033 from a base value of USD 546.9 million in 2024 at a CAGR of 8.3%.

- Regional Analysis: North America is expected to have the largest market share in the Global Rocker Arm Spot Welder Market with a share of about 43.9% in 2024.

- Key Players: Some of the major key players in the Global Rocker Arm Spot Welder Market are Spot Weld Inc., TECNA, T. J. Snow, ROUECHE COMPANY LLC, Standard Resistance Welder Company, Shenzhen Superwave Laser Technology, and many others.

- Global Growth Rate: The market is growing at a CAGR of 8.8 percent over the forecasted period.

Use Cases

- Automotive Industry: Rocker arm spot welders are widely used for assembling automotive body components, ensuring durable, high-quality welds in structures that demand both strength and lightness.

- Aerospace Manufacturing: These welders cater to the precision welding of such metal sheets that are utilized in aerospace applications. Reliability and adherence to even very stringent standards are primary.

- Electronics Industry: In electronics manufacturing, rocker arm spot welders allow precision and gentle welding for those parts where minimum distortion is required, especially in battery assembly.

- Construction and Infrastructure: These welders join metal sheets and structures to support robust assembly in infrastructure construction where longevity, resilience, and endurance are needed.

Market Dynamic

Trends in Rocker Arm Spot Welder Market

Advancements in Automation and Smart TechnologiesAutomation in the welding industry has turned a corner in changing the way manufacturers operate, with even higher precision, efficiency, and throughput. Robotic arms integrated with programmable controllers are increasingly integrated with rocker arm spot welders into hybrid systems for maximum output speeds, yet flexible enough to handle complex tasks.

Automated systems have employed sensors and AI-driven algorithms for real-time weld quality monitoring, with dynamic adjustment of parameters to improve the same. Such technological advancements reduce human error, lower labor costs, and enable support for mass customization, hence making automation take center stage in the rocker arm spot welder market.

Growing Demand for Electric Vehicle (EV) Manufacturing

The global trend of electric vehicles is shifting the direction of priority and manufacturing processes towards light construction and innovative materials. Applications of rocker arm spot welders find particular relevance in the manufacturing of EVs that allow for precision welding of materials such as aluminum and other light alloys, increasingly used to optimize weight-to-strength ratio in EV structures.

Demanding spot welding technologies that can address the use of thin, lightweight materials without compromising bond integrity, the scaling production of the EV makes EV manufacturing one of the major drivers in the advancement of rocker arm spot welding solutions.

Growth Drivers in Rocker Arm Spot Welder Market

Expanding Industrialization and Manufacturing Activities Globally

With continued industrialization in most emerging markets, especially in regions like Asia-Pacific and Latin America, the demand for trending, efficient, and reliable welding solutions has been high. As many manufacturing facilities are set up to accommodate the increasing demand from the automobile, construction, and electronics industries, so also is the need for versatile and durable welding technologies like rocker arm spot welders.

This expansion of the industry will create an enabling environment for the adoption of these welders, which are ideal for being solid and flexible while remaining reasonably affordable in a high-production setting.

Growing Aerospace and Defense Investments

Increased government and private investment in space industries and defense increases the demand for welding technologies that can deliver highly secure and strong joints. Rocker arm spot welders deliver unmatched consistency and precision that meet the high demands of both industries by ensuring good structural integrity in aircraft frame assembly among such applications and defense equipment manufacturing. It follows that with the growth of space aerospace and defense sectors in North America, Europe, and the Asia-Pacific region, the demands require more developed spot weld technologies.

Growth Opportunities Rocker Arm Spot Welder Market

Technological Advancements and R&D in Welding Technology

This is the evolutionary phase for welders. The manufacturers have tremendous opportunities to move toward advanced technologies such as monitoring in real-time, fully digital control systems, and augmented reality for operator training.

Advanced rocker arm spot welders enabled with IoT would be able to collect data related to preventive maintenance, remote monitoring, and optimization of welding parameters. These innovations create opportunities for welding equipment manufacturers to serve modernized production facilities that focus on digital transformation and smart manufacturing.

Expanding the Electric Vehicle Market as a Niche Segment

The rapid emergence of the electric vehicle market opens great opportunities for rocker arm spot welders since EV manufacturers are focusing on lightweight to achieve better energy efficiency. This demands more and more requirements of safe and high-quality welds in lighter and sometimes non-traditional materials, which is going to pose rocker arm spot welders for exclusivity.

This trend brings with it opportunities for manufacturers to develop special models that meet the particular needs of EV manufacturing, such as pre-set settings to handle battery packs or aluminum body panels.

Restraints Rocker Arm Spot Welder Market

High Initial Cost of Advanced Rocker Arm Spot Welders

While advanced welding technologies spontaneously bring significant advantages in operation, the high initial costs associated with such systems most of the time are out of budget for an SME. Fully automated and semi-automatic rocker arm spot welders come with IoT, real-time monitoring, and other advanced control systems.

These machines, because they are quite expensive, may not be adopted in masse by cost-sensitive manufacturers. This factor could restrain market growth in developing economies and for companies with low capital.

Limited Skilled Workforce and Operator Expertise

Advanced welding machinery requires a certain skill set to be operated. Currently, skilled welders are in shortage, hindering the market's growth. Industrial and special applications of rocker arm resistance spot welding require high proficiency related to weld quality and consistency from operators.

Each time a new and more technologically advanced model enters the market, the need would increase accordingly for skilled manpower to operate, maintain, and repair these machines.

An insufficient supply of qualified operators may slow down the growth rate in the adoption of advanced rocker arm spot welders in those regions where training programs or vocational education are not readily available.

Research Scope and Analysis

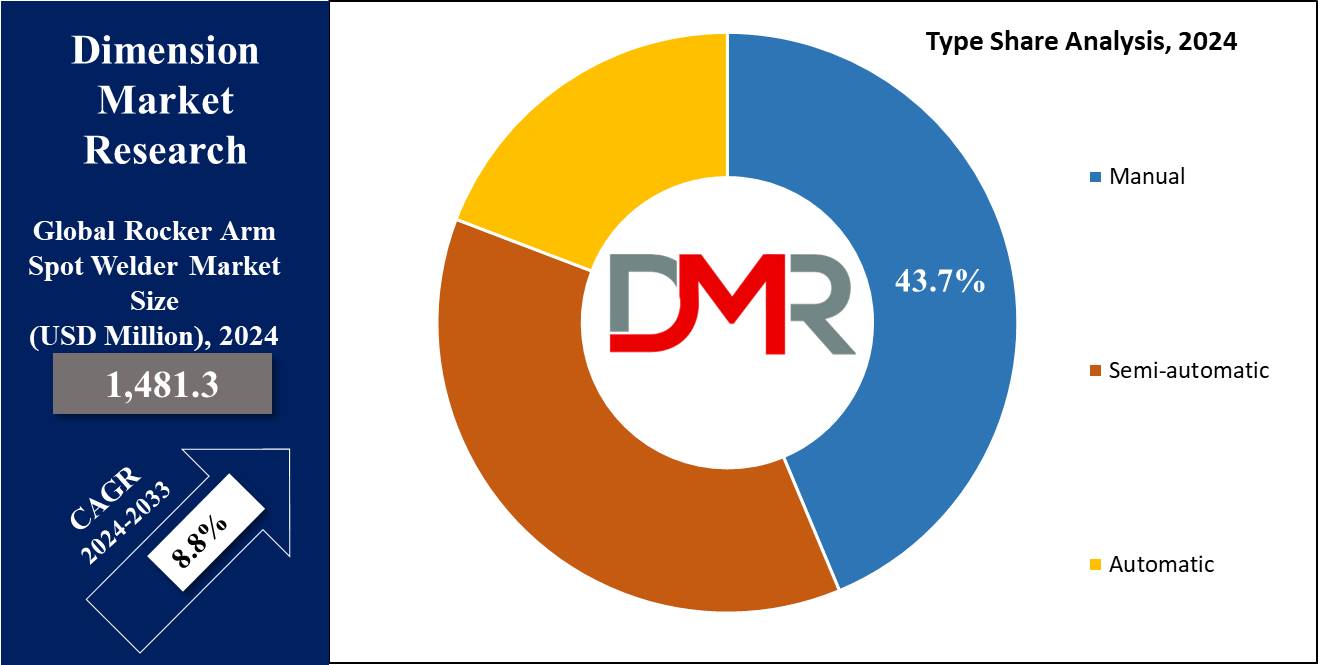

By Type Analysis

The manual type is projected to be the leading segment in the rocker arm spot welder market as it will hold 437% of the market share in 2024. The rocker arm spot welder market is dominated by the manual type due to its low cost, simplicity of operation, and wide applicability across various manufacturing contexts. Small and medium-sized manufacturers are acting to take advantage of using rocker arm welders manually, where operators appreciate the freedom to make adaptive changes to parameters on the spot to meet particular welding needs.

This gives manual welders a special value again when it comes to operations in automotive, aerospace-based production, or general manufacturing units, which require critical and precision welds in operations. The basic acceptance of manual welders allows operators to make each weld according to their given requirements, very crucial to several quality and precision guarantees attached to every weld of intricate components.

Another positive aspect concerns manual welders, as they entail relatively lower investment costs; this makes them more accessible to smaller enterprises or to those operating in regions where labor costs are lower. Manual welders also require less complex setup and training; this decreases downtime and allows faster integration into operations. They may also be more resistant to wear and tear and can be easier to maintain, thereby prolonging their lifespan and therefore may offer an economical option when longevity and budgets become more important than automation to a business. Considering these points, the manual type will likely continue carrying the torch, since it offers a more even blend of efficiency, economics, and versatility.

By Application Analysis

Industrial sectors, particularly automotive, aerospace, and construction, are projected to be primary users in the rocker arm spot welder market with 44.9% of the market share in 2024. For such industries, high-strength and reliable welds are necessary to guarantee the structural integrity and safety of their products; hence, rocker arm spot welders become indispensable.

The automotive industry is just one sector where rocker arm welders are put to wide use in body and chassis production, where the strength and precision of each weld quite literally determine the safety and durability of the vehicle. With body panels and frames calling for consistent and high-quality the backbones to most features in vehicle safety rocker arm welder truly is a favorite. In aerospace, similar quality requirements apply: it is of critical importance to construct light but strong aircraft components by welding.

Rocker arm spot welders provide the control and precision needed to manipulate lightweight alloys and other advanced materials, and therefore, come in quite handy in this respect. The same goes for structural elements such as beams and metal frameworks that are necessary to give a structure its robust look. Industrial application can therefore be expected to continue leading the application segment, given in this case how much these high-demand sectors rely on precision welding, with rocker arm spot welding being one of these technologies that is proven reliable and strong.

The Rocker Arm Spot Welder Market Report is segmented on the basis of the following

By Type

- Manual

- Semi-automatic

- Automatic

By Application

- Industrial

- Construction

- Others

Regional Analysis

North America is projected to dominate the global rocker arm spot welder market as it is anticipated to

hold 43.9% of the market share in 2024. The main share in the market of rocker arm spot welders is held by North America, driven by the United States, due to a strong manufacturing sector and wide investment in automation technologies.

High demand for precision welding in North America is dictated by the automotive and aerospace industries for serving such major output contributors of the regional economy. For instance, the automotive industry in the United States requires reliable welding of all body frames and panels. Applications in aeronautics require welds to be lightweight and durable to craft aircraft parts. Stringent quality and safety standards are basic in both sectors; hence, North America is a strong market for solutions offering high-performance welding.

Also, investments in North America in research and development have led to improvements in welding technologies related to automation, energy efficiency, and digital controls. The development of such innovative technologies is bound to prove beneficial for not only the reliability of the rocker arm spot welders but also their usage across various industries. Besides, the quality labor class in North America helps the region to operate advanced machinery of welding. This is competitive enough for the region to emerge as a quality manufacturer of both high-volume and custom welding output. All these industries continuing to adopt advanced manufacturing solutions means that North America is never going to perish in the market leadership of rocker arm spot welders.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The market for rocker arm spot welders is presently aggressive, and the leading competitors will focus on technological developments and innovation as a strategic approach toward gaining market share. Firms like Taylor-Winfield Technologies, TJ Snow Company, and Mechelonic Welders have a powerful market position since they have earned a reputation in the market for offering reliable equipment with very high quality. Serious investment in R&D by leading firms makes them capable of producing welding solutions with automation, energy efficiency, and customization that meet diversified industrial applications.

New entrants, like Weld Plus and Seedorff Acme Corporation, are also increasing competition with their niche solutions that cater to specific industry needs of this market. Many such companies focus their attention on offering value-added features such as improved control and digital monitoring to attract industries with specialized welding needs. Competitiveness in the market demonstrates partnership and collaboration with key industries, such as automotive and aerospace, to increase market reach and establish brand reliability. Innovation and customization drives in welding solutions continue to raise the bar in the market, which is highly dynamic and competitive.

Some of the prominent players in the Global Rocker Arm Spot Welder Market are

- Tecna

- ABB Robotics

- Taylor Winfield

- Ceaweld

- Spot Weld Inc

- TECNA

- T. J. Snow

- ROUECHE COMPANY LLC

- Standard Resistance Welder Company

- Shenzhen Superwave Laser Technology

- Other Key Players

Recent Developments

- In October 2024, Taylor-Winfield launched a high-efficiency series of rocker arm spot welders designed to meet the automotive industry's need for precision welding in lightweight vehicle structures.

- In August 2024, Mechelonic Welders expanded its market presence into Europe, introducing advanced rocker arm welders to address increasing demands for high-quality welding solutions.

- In December 2023, TJ Snow introduced a customizable automation feature in its rocker arm welders to better serve aerospace applications requiring high precision.

- In September 2023, Weld Plus unveiled an energy-efficient model of its rocker arm welders, aligning with sustainability initiatives in manufacturing.

- In November 2022, Seedorff Acme Corporation enhanced its product line with rocker arm welders compatible with digital monitoring systems, enabling improved quality control in production.

Report Details

| Report Characteristics |

| Market Size (2024) |

USD 1,481.3 Mn |

| Forecast Value (2033) |

USD 3,171.3 Mn |

| CAGR (2024-2033) |

8.8% |

| Historical Data |

2018 – 2023 |

| The US Market Size (2024) |

USD 546.9 Mn |

| Forecast Data |

2025 – 2033 |

| Base Year |

2023 |

| Estimate Year |

2024 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Type (Manual, Semi-automatic, and Automatic), By Application (Industrial, Construction, and Others) |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia- Pacific– China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA

|

| Prominent Players |

Tecna, ABB Robotics, Taylor Winfield, Ceaweld, Spot Weld Inc, TECNA, T. J. Snow, ROUECHE COMPANY LLC, Standard Resistance Welder Company, Shenzhen Superwave Laser Technology, and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users) and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |

Frequently Asked Questions

The Global Rocker Arm Spot Welder Market size is estimated to have a value of USD 1,481.3 million in 2024 and is expected to reach USD 3,171.3 million by the end of 2033.

The US Rocker Arm Spot Welder Market is projected to be valued at USD 546.9 million in 2024. It is expected to witness subsequent growth in the upcoming period as it holds USD 1,117.6 million in 2033 at a CAGR of 8.3%.

North America is expected to have the largest market share in the Global Rocker Arm Spot Welder Market with a share of about 43.9% in 2024.

Some of the major key players in the Global Rocker Arm Spot Welder Market are Spot Weld Inc TECNA, T. J. Snow, ROUECHE COMPANY LLC, Standard Resistance Welder Company, Shenzhen Superwave Laser Technology, and many others.