Market Overview

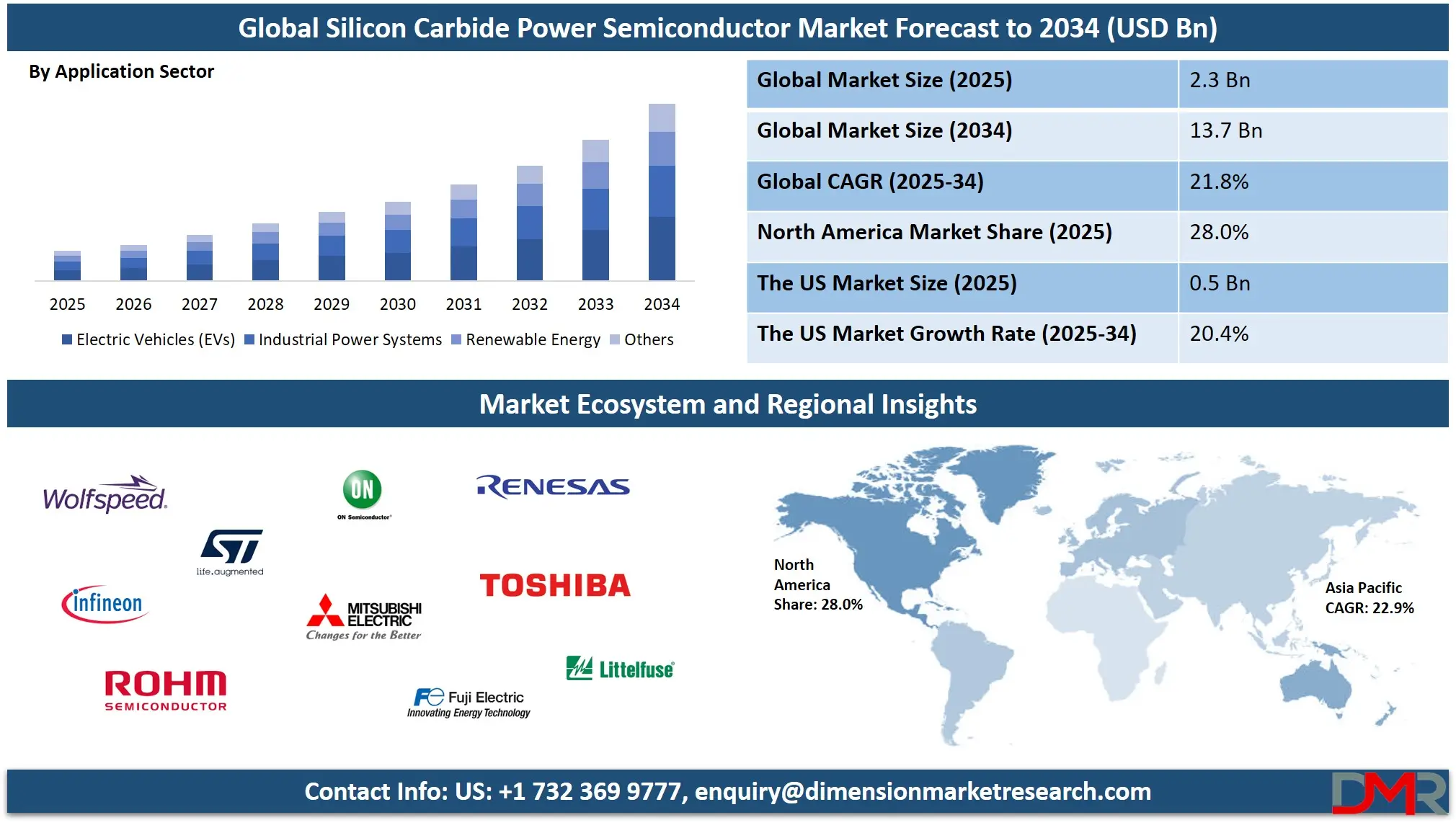

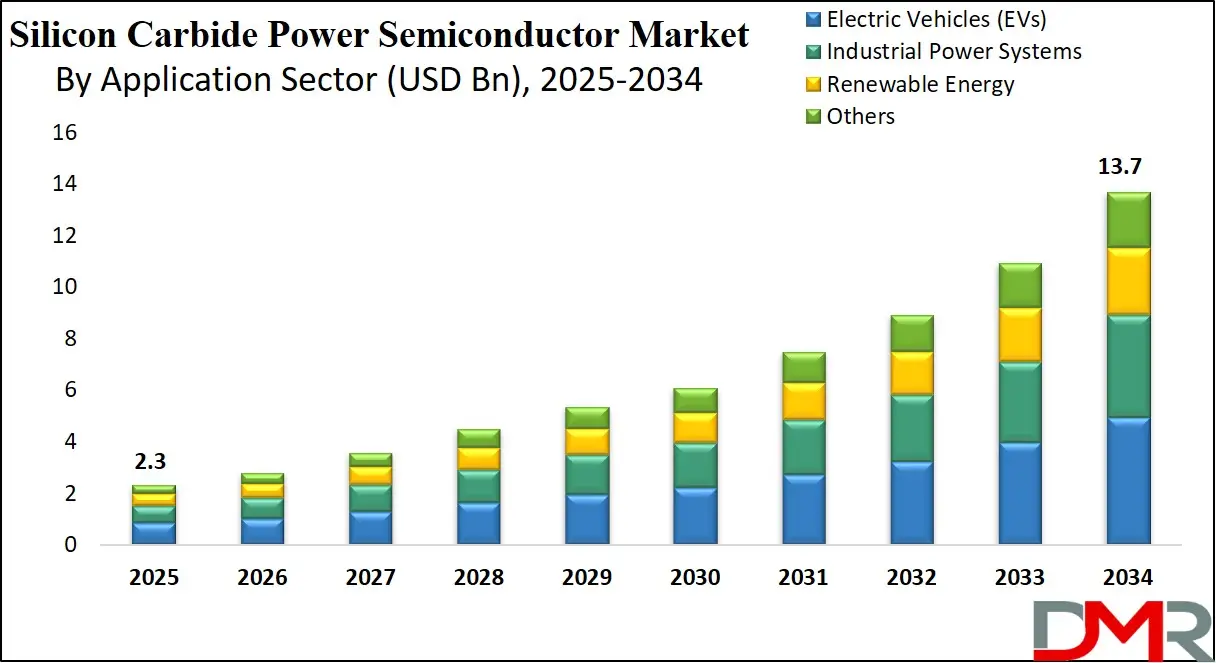

The global Silicon Carbide (SiC) power semiconductor market is projected to grow from USD 2.3 billion in 2025 to USD 13.7 billion by 2034, registering a strong CAGR of 21.8%. This growth is driven by rising demand for high-efficiency power electronics, growing electric vehicle (EV) adoption, and expanding renewable energy applications, positioning SiC devices as a core component in next-gen energy systems and advanced power conversion solutions.

Silicon Carbide (SiC) power semiconductors are advanced electronic components designed to operate at high temperatures, voltages, and frequencies, offering superior efficiency and thermal performance compared to traditional silicon-based devices. These semiconductors are fabricated using silicon carbide material, which possesses a wider bandgap, higher breakdown electric field strength, and greater thermal conductivity.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

As a result, SiC devices such as MOSFETs, Schottky diodes, and power modules are increasingly used in power conversion systems, where minimizing energy loss and managing heat are critical. SiC technology is particularly advantageous for applications requiring compact designs, fast switching speeds, and high-power density, including electric vehicles, renewable energy systems, and industrial power electronics.

The global Silicon Carbide (SiC) power semiconductor market is experiencing rapid growth driven by the rising adoption of electric vehicles, increased deployment of renewable energy infrastructure, and the ongoing shift toward energy-efficient power electronics. Governments across major economies are offering strong policy support and incentives for sustainable technologies, fueling the demand for high-performance SiC-based devices.

Automakers are integrating SiC components into EV inverters and onboard chargers to improve range, reduce charging time, and enhance energy efficiency. In the industrial sector, SiC semiconductors are being deployed in motor drives, high-frequency power supplies, and automation systems where reliability and performance under harsh conditions are essential.

Furthermore, the market is witnessing technological advancements such as the development of 1200V and 1700V SiC MOSFETs and the emergence of integrated SiC power modules for compact system designs. Supply chain expansions, including the setup of dedicated SiC wafer fabs and partnerships between chipmakers and automotive OEMs, are strengthening the global production ecosystem.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Asia Pacific dominates the market due to robust manufacturing infrastructure and EV proliferation in countries like China and Japan, while North America and Europe are also showing strong growth driven by innovation and sustainability targets. With ongoing R&D efforts, the SiC power semiconductor industry is poised to become a cornerstone in next-generation power electronics solutions.

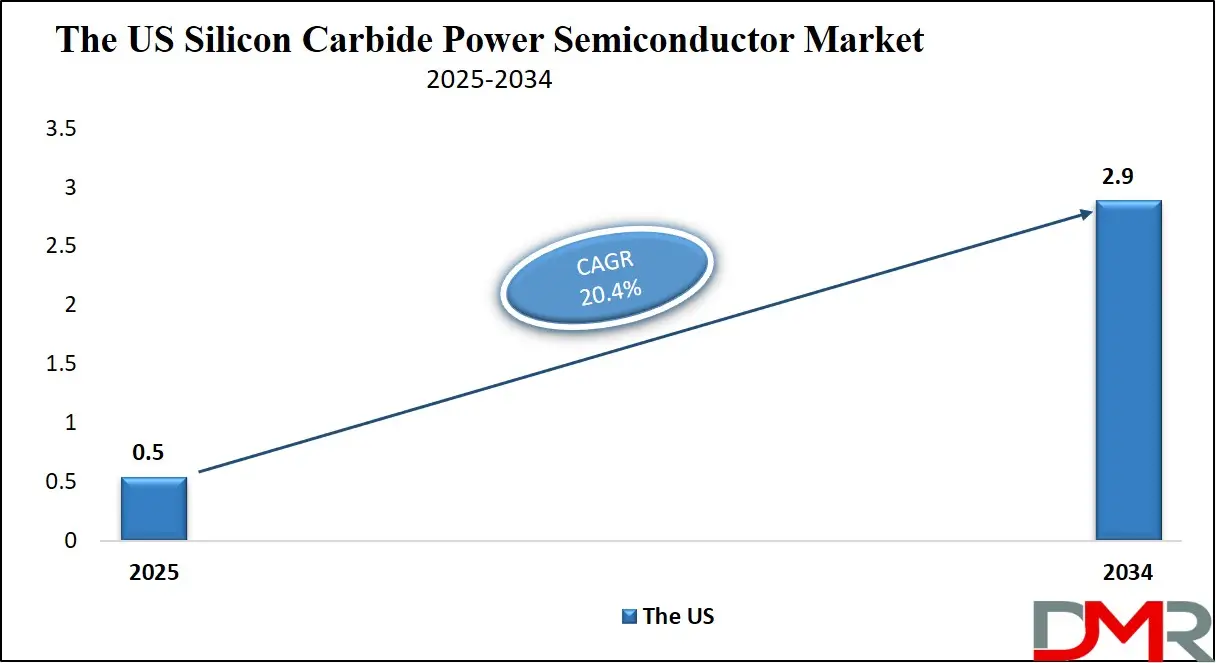

The US Silicon Carbide Power Semiconductor Market

The U.S. Silicon Carbide Power Semiconductor market size is projected to be valued at USD 0.5 billion by 2025. It is further expected to witness subsequent growth in the upcoming period, holding USD 2.9 billion in 2034 at a CAGR of 20.4%.

The United States Silicon Carbide (SiC) power semiconductor market is witnessing robust expansion, fueled by rising investments in electric mobility, grid modernization, and energy-efficient power infrastructure. With the growing emphasis on clean energy and carbon neutrality goals, SiC-based devices such as MOSFETs and Schottky diodes are gaining traction across critical sectors including electric vehicles, solar inverters, and industrial motor drives.

The U.S. government’s support for domestic semiconductor manufacturing through programs like the CHIPS and Science Act has further encouraged the development of SiC fabrication facilities and wafer production plants, enhancing the local supply chain. Key players in the U.S., including Wolfspeed and ON Semiconductor, are at the forefront of advancing SiC technology, delivering high-performance solutions for power electronics in high-voltage and high-temperature environments.

Moreover, the U.S. market is characterized by rapid technological innovation and strategic collaborations between OEMs, Tier-1 suppliers, and semiconductor foundries. The demand for Silicon Carbide power modules is growing rapidly in the EV ecosystem, where automotive manufacturers are integrating SiC-based inverters and DC-DC converters to extend vehicle range and improve efficiency.

Additionally, the growing adoption of fast-charging infrastructure and smart grid technologies is creating a fertile ground for SiC applications. In the aerospace and defense sectors, SiC devices are being utilized for lightweight, compact, and reliable power systems in high-stress conditions. With a strong focus on R&D and government-backed incentives, the U.S. Silicon Carbide power semiconductor market is positioned as a global innovation hub, driving scalable, energy-efficient power solutions across industries.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Europe Silicon Carbide Power Semiconductor Market

In 2025, Europe’s Silicon Carbide (SiC) power semiconductor market is estimated to reach approximately USD 500 million, underscoring the region’s strong commitment to electrification, sustainability, and advanced power electronics. This market strength is largely attributed to the growing demand for energy-efficient components in electric vehicles, renewable energy infrastructure, and industrial automation systems.

Countries like Germany, France, and the Netherlands are actively promoting green energy initiatives, EV manufacturing, and smart grid deployment—all of which heavily rely on SiC-based devices for their superior power density, thermal performance, and energy conversion efficiency. European semiconductor players are also investing in R&D to localize production and reduce dependency on foreign chip supply chains, further boosting market confidence.

With a projected compound annual growth rate (CAGR) of 20.5% from 2025 to 2034, the European SiC power semiconductor market is poised for accelerated expansion. Regulatory mandates for carbon neutrality and CO₂ emission reductions are pushing automotive OEMs and energy providers to adopt next-generation power electronics based on SiC technology.

In addition, the region is witnessing a surge in funding and strategic partnerships between semiconductor companies and automakers to develop localized SiC supply chains. The push toward wide bandgap semiconductors is gaining momentum across various industries, positioning Europe not only as a key consumer but also as a technology developer in the global SiC power semiconductor ecosystem.

Japan Silicon Carbide Power Semiconductor Market

Japan’s Silicon Carbide (SiC) power semiconductor market is projected to reach approximately USD 200 million in 2025, reflecting the country’s steady transition toward high-efficiency, compact, and sustainable power electronics. Japan’s leadership in automotive innovation, especially hybrid and electric vehicles, plays a central role in driving SiC adoption.

Major Japanese automakers and Tier 1 suppliers are increasingly integrating SiC MOSFETs and Schottky diodes into powertrains, charging systems, and electric drive units to boost energy efficiency and reduce heat loss. In addition to the automotive sector, SiC devices are also gaining traction in Japan’s railway systems, smart grid infrastructure, and industrial automation, where reliability and compact design are essential.

With a projected CAGR of 19.2% from 2025 to 2034, Japan’s SiC market is set to expand significantly, supported by government-backed innovation programs and public-private partnerships aimed at strengthening the domestic semiconductor ecosystem. Leading Japanese electronics firms are investing in SiC R&D and collaborating with global players to scale production and improve device performance.

Furthermore, Japan’s strategic emphasis on energy security and carbon reduction is fostering rapid deployment of renewable energy technologies and storage systems, both of which benefit from the superior power-handling capabilities of SiC semiconductors. This growth outlook positions Japan as a critical regional player contributing to the global SiC power semiconductor value chain.

Global Silicon Carbide Power Semiconductor Market: Key Takeaways

- Market Value: The global silicon carbide power semiconductor market size is expected to reach a value of USD 13.7 billion by 2034 from a base value of USD 2.3 billion in 2025 at a CAGR of 21.8%.

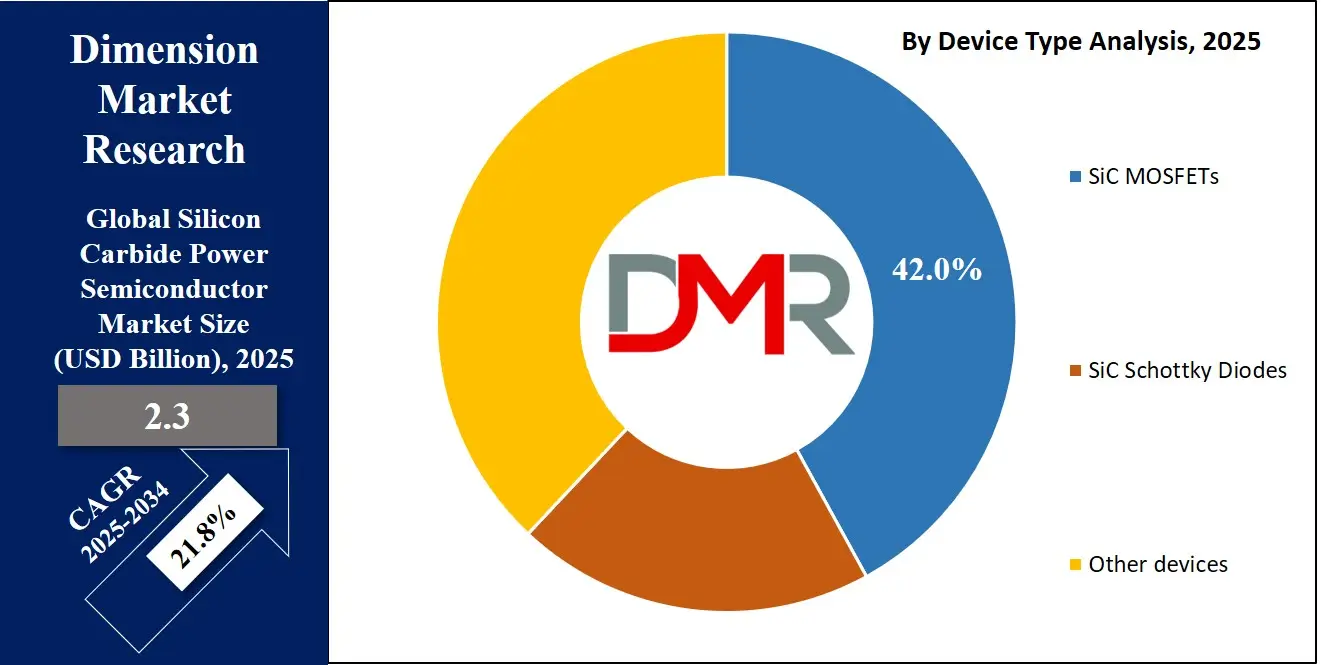

- By Device Type Segment Analysis: SiC MOSFETs are expected to maintain their dominance in the device type segment, capturing 42.0% of the total market share in 2025.

- By Application Sector Segment Analysis: Electric Vehicles (EVs) are anticipated to dominate the application sector segment, capturing 36.0% of the total market share in 2025.

- By End-User Segment Analysis: The industrial sector is poised to consolidate its dominance in the tourist type segment, capturing 60.0% of the market share in 2025.

- Regional Analysis: Asia Pacific is anticipated to lead the global silicon carbide power semiconductor market landscape with 37.0% of total global market revenue in 2025.

- Key Players: Some key players in the global silicon carbide power semiconductor market are Wolfspeed, STMicroelectronics, Infineon Technologies, ROHM Semiconductor, ON Semiconductor, Mitsubishi Electric, Fuji Electric, Renesas Electronics, Toshiba Corporation, Littelfuse, GeneSiC Semiconductor, Microchip Technology, Vishay Intertechnology, Semikron Danfoss, Texas Instruments, Global Power Technologies Group (GPTG), Power Integrations, Alpha & Omega Semiconductor, and Others.

Global Silicon Carbide Power Semiconductor Market: Use Cases

- Electric Vehicle (EV) Powertrains: Silicon Carbide power semiconductors are increasingly integrated into electric vehicle powertrain systems, including traction inverters, DC-DC converters, and onboard chargers. These components support higher switching frequencies and lower energy losses compared to traditional silicon devices, enabling improved driving range, smaller system footprints, and better thermal performance. Automotive OEMs are leveraging SiC technology to meet the demand for high-efficiency EVs and faster charging capabilities.

- Renewable Energy Systems: SiC semiconductors are vital in renewable energy applications such as solar PV inverters and wind turbine converters. They enhance energy conversion efficiency, reduce thermal losses, and enable operation at higher voltages. This improves power density and reliability in utility-scale solar farms and decentralized power systems. The adoption of SiC devices supports smoother grid integration and more efficient renewable energy output.

- Industrial Motor Drives and Automation: Industrial sectors rely on SiC power devices in motor drives, power supplies, and automation equipment to boost energy efficiency and reduce operational costs. These components are ideal for high-power, high-frequency applications, offering compact size and high-temperature tolerance. Industries such as manufacturing, robotics, and logistics benefit from enhanced productivity and system reliability through SiC integration.

- Data Centers and Power Infrastructure: With rising global data consumption, data centers demand energy-efficient power management solutions. SiC power semiconductors are used in power supplies and backup systems to minimize energy losses and ensure stable operation under continuous high loads. In broader power infrastructure, SiC devices enable the development of smart grids and high-voltage direct current (HVDC) systems, supporting reliable, long-distance energy transmission with minimal loss.

Impact of Artificial Intelligence on Silicon Carbide Power Semiconductor Market

Artificial Intelligence (AI) is significantly influencing the Silicon Carbide power semiconductor market by enhancing design optimization, manufacturing efficiency, and system-level performance. AI-driven simulation tools are enabling semiconductor manufacturers to model, test, and validate SiC devices with higher precision and speed, reducing development cycles and improving device reliability. This is particularly valuable in applications where SiC is used in complex power systems such as EVs, industrial automation, and renewable energy grids, where performance under varying loads and conditions must be accurately predicted.

In addition, AI is transforming the deployment of SiC devices across end-use sectors by enabling smarter energy management and predictive maintenance. For example, in electric vehicles and smart grids, AI algorithms analyze real-time data from SiC-based power systems to optimize energy usage, monitor device health, and prevent failures. This not only extends the lifespan of SiC components but also supports energy-efficient operations.

Furthermore, AI-integrated manufacturing processes, such as defect detection and wafer inspection, are improving yield rates and reducing production costs, making SiC solutions more accessible at scale. As AI continues to evolve, its integration with Silicon Carbide technology will accelerate innovation and unlock new levels of performance across power electronics applications.

Global Silicon Carbide Power Semiconductor Market: Stats & Facts

- U.S. Department of Energy / Clean Energy Manufacturing (NREL, 2017)

- As of 2017, SiC wafer and device manufacturing was concentrated across the United States, Japan, and Europe, with chip production split roughly equally among these regions.

- The U.S. maintained a competitive edge in 150mm wafer production, while Japan led in high-volume device fabrication.

- Europe focused on advanced power module integration using SiC substrates.

- National Science Foundation (NSF) – Innovative SiC Production

- NSF funded the development of a low-cost sustainable process to produce high-purity SiC powder at approximately USD 10–$20 per kg.

- This method achieved up to 75% lower CO₂ emissions compared to traditional production processes.

- The project emphasized scaling for commercial SiC substrate supply in North America.

- NASA / Entangled Photon Source in SiC (2024)

- Researchers at NIST demonstrated an integrated SiC-based entangled photon source suitable for quantum communication applications.

- The system achieved a coincidence-to-accidental ratio above 600 at telecom wavelengths.

- The heralded single-photon generation rate reached (9 ± 1) × 10³ pairs per second with quantum interference visibility exceeding 99%.

- State of New York – Semiconductor R&D Facility (2025)

- In July 2025, New York announced a USD 20 million investment in a state-of-the-art semiconductor research facility at Stony Brook University.

- The facility is focused on SiC crystal growth, materials metrology, and advanced substrate development.

- The initiative included an USD 8 million private sector investment from onsemi to support collaborative research.

- White House – Microelectronics Research Strategy (2025)

- A 2025 federal strategy identified SiC as a key emerging material in power electronics and microelectronics R&D.

- The report emphasized SiC’s advantages in high-voltage, high-frequency, and high-temperature conditions.

- The material was highlighted for its strategic importance in national energy efficiency goals and automotive electrification.

- USTR Hearing – Semiconductors and National Security (2025)

- A preliminary USTR hearing in 2025 noted concerns over China's rapidly increasing SiC wafer production capacity.

- U.S. agencies flagged the need for diversified and resilient domestic supply chains in strategic semiconductor materials.

- The report suggested expanded collaboration between federal labs and commercial SiC fabrication partners.

Global Silicon Carbide Power Semiconductor Market: Market Dynamics

Global Silicon Carbide Power Semiconductor Market: Driving Factors

Rising Adoption of Electric Vehicles (EVs)

The surging demand for electric vehicles is a major growth driver for the SiC power semiconductor market. SiC-based MOSFETs and Schottky diodes enable more efficient power conversion in EV inverters, battery chargers, and power control units. Automakers are increasingly integrating SiC technology to enhance battery performance, extend driving range, and support ultra-fast charging. With regulatory mandates pushing for zero-emission transport, the use of SiC components is becoming a standard in next-generation EV power electronics.

Demand for High-Efficiency Power Solutions in Renewable Energy

As global energy systems transition toward clean and decentralized sources, SiC power devices are essential in solar inverters, wind energy converters, and energy storage systems. Their ability to handle high voltages and temperatures with minimal switching losses makes them ideal for high-efficiency energy conversion. SiC helps improve power density and grid stability in solar PV installations, especially in utility-scale and hybrid renewable power plants.

Global Silicon Carbide Power Semiconductor Market: Restraints

High Production Costs of SiC Wafers and Devices

One of the primary challenges facing this market is the high cost of raw materials and fabrication processes. Producing SiC wafers requires complex techniques such as chemical vapor deposition and advanced crystal growth, making them significantly more expensive than traditional silicon wafers. These elevated costs limit broader adoption, particularly in cost-sensitive markets and small-scale applications.

Limited Availability of Manufacturing Infrastructure

The global supply chain for SiC devices is still maturing, with relatively few foundries capable of producing high-purity, defect-free SiC wafers at scale. The lack of large-scale manufacturing facilities and skilled labor also restricts the ability of some manufacturers to meet growing demand. Supply constraints and longer lead times can hinder OEMs from scaling production of SiC-based systems.

Global Silicon Carbide Power Semiconductor Market: Opportunities

Expansion of Fast-Charging Infrastructure

The global rollout of EV fast-charging networks presents a lucrative opportunity for SiC power semiconductor adoption. SiC devices are highly suitable for high-voltage, high-frequency converters used in fast-charging stations, offering superior efficiency and compact design. As governments and private players invest in EV infrastructure, the demand for SiC components in chargers, rectifiers, and grid interfaces is set to rise rapidly.

Integration into Aerospace and Defense Systems

The aerospace and defense sectors are exploring SiC for its ability to perform under extreme conditions, including high altitudes and intense thermal stress. SiC power modules are being integrated into satellite power systems, avionics, and electric propulsion units due to their lightweight form factor and reliability. This niche but critical market offers potential for specialized SiC solutions with high margins and long-term contracts.

Global Silicon Carbide Power Semiconductor Market: Trends

Development of 200mm SiC Wafers

A major industry trend is the shift toward 200mm SiC wafers, which allow more chips per wafer and reduce overall production cost per device. Leading semiconductor manufacturers are investing in 200mm wafer fabs to boost output and support growing market demand. This transition enhances economies of scale and is expected to make SiC devices more cost-competitive with traditional silicon solutions.

AI-Driven Process Automation in SiC Manufacturing

Artificial Intelligence and machine learning are being increasingly integrated into SiC manufacturing processes. From predictive defect detection to process optimization and yield improvement, AI technologies are helping streamline production. This trend is accelerating the development of high-performance, reliable SiC power devices and reducing time-to-market for new product launches.

Global Silicon Carbide Power Semiconductor Market: Research Scope and Analysis

By Device Type Analysis

In the device type segment of the Silicon Carbide (SiC) power semiconductor market, SiC MOSFETs are anticipated to remain the dominant component, accounting for 42.0% of the total market share in 2025. This strong position is primarily attributed to their superior performance in high-voltage and high-frequency applications compared to traditional silicon-based transistors.

SiC MOSFETs offer lower switching losses, higher efficiency, and better thermal conductivity, making them an ideal choice for use in electric vehicles, renewable energy inverters, and industrial motor drives. Their ability to reduce energy consumption and system size while improving power density has driven widespread adoption, especially as industries push toward more compact and efficient designs in high-power systems.

Alongside MOSFETs, SiC Schottky diodes play a crucial role in this market, especially in applications requiring high-speed switching and low forward voltage drop. These diodes are widely used in power factor correction circuits, switched-mode power supplies, and solar inverters, where fast recovery time and reduced power losses are critical. SiC Schottky diodes help minimize conduction and switching losses, enhance system reliability, and operate efficiently under high temperature and voltage conditions. Their integration into various end-use sectors complements the capabilities of SiC MOSFETs, supporting the overall growth and performance advantages offered by SiC-based power electronics.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

By Application Sector Analysis

In the application sector segment of the Silicon Carbide (SiC) power semiconductor market, electric vehicles (EVs) are expected to lead by capturing 36.0% of the total market share in 2025. This dominance is driven by the growing global shift toward electrified transportation and the rising demand for efficient, lightweight, and high-performance power components within EV systems.

SiC power semiconductors are increasingly integrated into traction inverters, onboard chargers, and DC-DC converters, where they help reduce switching losses, enhance thermal management, and enable faster charging speeds. Automakers are rapidly adopting SiC devices to extend driving range, minimize battery size, and improve overall energy efficiency, making them a core technology in next-generation electric mobility.

In addition to EVs, industrial power systems represent a significant segment of the SiC semiconductor market, driven by the need for high-efficiency power conversion in sectors such as manufacturing, automation, and heavy equipment. SiC components are used in motor drives, uninterruptible power supplies (UPS), and high-frequency converters, where they contribute to reduced energy consumption, smaller system size, and higher operational reliability.

Industrial applications benefit from the high-temperature and high-voltage capabilities of SiC devices, especially in harsh environments and continuous-use scenarios. As industries pursue automation and energy optimization, the role of SiC semiconductors in industrial power systems is expected to grow steadily, complementing their rapid adoption in the automotive sector.

By End-User Analysis

In the end-user segment of the Silicon Carbide (SiC) power semiconductor market, the industrial sector is set to maintain a dominant position, accounting for 60.0% of the total market share in 2025. This dominance is largely due to the sector's widespread demand for high-efficiency, durable, and compact power solutions across a range of applications such as motor drives, power supplies, robotics, and heavy machinery.

SiC devices offer key advantages like higher switching speeds, better thermal stability, and improved energy efficiency, making them ideal for use in high-load and high-temperature environments typical of industrial operations. As industries continue to modernize with smart manufacturing, automation, and energy management systems, the integration of SiC technology becomes essential for achieving performance optimization and long-term cost savings.

The automotive sector, while slightly behind in share, is rapidly emerging as a key growth area for SiC power semiconductors. With the growing penetration of electric vehicles, plug-in hybrids, and advanced driver assistance systems (ADAS), the need for compact, efficient, and high-performance power electronics has intensified.

SiC components are being incorporated into EV powertrains, battery management systems, and fast-charging modules to reduce energy losses and enable higher power density. As OEMs strive to meet fuel efficiency and emissions regulations while enhancing vehicle performance, the automotive industry is expected to significantly expand its adoption of SiC technology in the coming years.

The Silicon Carbide Power Semiconductor Market Report is segmented on the basis of the following:

By Device Type

- SiC MOSFETs

- SiC Schottky Diodes

- Other Devices

By Application Sector

- Electric Vehicles (EVs)

- Industrial Power Systems

- Renewable Energy

- Others

By End-User

- Industrial

- Automotive

- Energy & Power

- IT & Telecom

- Aerospace & Defense

- Other Sectors

Global Silicon Carbide Power Semiconductor Market: Regional Analysis

Region with the Largest Revenue Share

Asia Pacific is expected to dominate the global silicon carbide power semiconductor market in 2025, capturing 37.0% of the total market revenue. This regional leadership is driven by the strong presence of semiconductor manufacturing hubs, rapid industrialization, and the growing adoption of electric vehicles in countries like China, Japan, and South Korea. Government initiatives promoting clean energy, integrated with large-scale investments in renewable power infrastructure and EV charging networks, are further fueling demand for SiC-based devices.

Additionally, the expansion of local supply chains, technological advancements, and strategic partnerships among regional manufacturers are strengthening Asia Pacific’s position as a key contributor to the global SiC power semiconductor landscape.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Region with significant growth

North America is projected to witness significant growth in the silicon carbide power semiconductor market over the coming years, driven by growing adoption of electric vehicles, advancements in renewable energy projects, and modernization of power infrastructure. The region benefits from strong government support through policies like the Inflation Reduction Act and the CHIPS Act, which are boosting domestic semiconductor manufacturing and clean energy investments.

Additionally, the presence of key industry players, rising demand for fast-charging networks, and growing focus on energy-efficient technologies in data centers and industrial automation are accelerating the uptake of SiC devices. This combination of regulatory support, innovation, and industrial demand positions North America as a rapidly expanding market for SiC power semiconductors.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Global Silicon Carbide Power Semiconductor Market: Competitive Landscape

The global competitive landscape of the silicon carbide power semiconductor market is marked by intense innovation, strategic partnerships, and capacity expansions among leading players aiming to capture a larger share in high-growth applications such as electric vehicles, industrial automation, and renewable energy. Companies like Wolfspeed, STMicroelectronics, Infineon Technologies, and ROHM Semiconductor are at the forefront, investing heavily in 200mm SiC wafer production, vertical integration, and product innovation to enhance performance and scalability.

Mergers, acquisitions, and collaborations with automotive OEMs and energy solution providers are common strategies to accelerate commercialization and secure long-term supply agreements. Additionally, emerging players and regional foundries are entering the market, intensifying competition and driving advancements in cost reduction and manufacturing efficiency. As demand grows, the competitive environment is expected to remain dynamic, with a focus on technology leadership and securing reliable, high-volume supply chains.

Some of the prominent players in the global silicon carbide power semiconductor market are:

- Wolfspeed

- STMicroelectronics

- Infineon Technologies

- ROHM Semiconductor

- ON Semiconductor

- Mitsubishi Electric

- Fuji Electric

- Renesas Electronics

- Toshiba Corporation

- Littelfuse

- GeneSiC Semiconductor

- Microchip Technology

- Vishay Intertechnology

- Semikron Danfoss

- Texas Instruments

- Global Power Technologies Group (GPTG)

- Power Integrations

- Alpha & Omega Semiconductor

- United Silicon Carbide (now part of Qorvo)

- X-Fab Silicon Foundries

- Other Key Players

Global Silicon Carbide Power Semiconductor Market: Recent Developments

- January 2025: Wolfspeed introduced its fourth-generation Gen 4 SiC MOSFET technology platform, offered in 750V, 1200V, and 2300V nodes, including power modules, discrete components, and bare-die options.

- March 2025: At APEC 2025, Wolfspeed showcased its Gen 4 SiC MOSFET advancements alongside the scalability benefits of 200 mm wafer fabrication, highlighting performance improvements applicable to EVs, renewable energy, and industrial sectors.

- January 2025: onsemi completed its acquisition of Qorvo’s SiC JFET technology business (including United Silicon Carbide) for USD 115 million, bolstering its EliteSiC portfolio and extending its reach in AI, EV, and industrial applications.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 2.3 Bn |

| Forecast Value (2034) |

USD 13.7 Bn |

| CAGR (2025–2034) |

21.8% |

| Historical Data |

2019 – 2024 |

| The US Market Size (2025) |

USD 0.5 Bn |

| Forecast Data |

2025 – 2033 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors, etc. |

| Segments Covered |

By Device Type (SiC MOSFETs, SiC Schottky Diodes, Other Devices), By Application Sector (Electric Vehicles (EVs), Industrial Power Systems, Renewable Energy, Others), and By End-User (Industrial, Automotive, Energy & Power, IT & Telecom, Aerospace & Defense, Other Sectors |

| Regional Coverage |

North America – US, Canada; Europe – Germany, UK, France, Russia, Spain, Italy, Benelux, Nordic, Rest of Europe; Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, Rest of MEA |

| Prominent Players |

Wolfspeed, STMicroelectronics, Infineon Technologies, ROHM Semiconductor, ON Semiconductor, Mitsubishi Electric, Fuji Electric, Renesas Electronics, Toshiba Corporation, Littelfuse, GeneSiC Semiconductor, Microchip Technology, Vishay Intertechnology, Semikron Danfoss, Texas Instruments, Global Power Technologies Group (GPTG), Power Integrations, Alpha & Omega Semiconductor, and Others |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days, and 5 analysts working days respectively. |

Frequently Asked Questions

How big is the global silicon carbide power semiconductor market?

▾ The global silicon carbide power semiconductor market size is estimated to have a value of USD 2.3

billion in 2025 and is expected to reach USD 13.7 billion by the end of 2034.

What is the size of the US silicon carbide power semiconductor market?

▾ The US silicon carbide power semiconductor market is projected to be valued at USD 0.5 billion in 2025.

It is expected to witness subsequent growth in the upcoming period as it holds USD 2.9 billion in 2034 at

a CAGR of 20.4%.

Which region accounted for the largest global silicon carbide power semiconductor market?

▾ Asia Pacific is expected to have the largest market share in the global silicon carbide power

semiconductor market, with a share of about 37.0% in 2025.

Who are the key players in the global silicon carbide power semiconductor market?

▾ Some of the major key players in the global silicon carbide power semiconductor market are Wolfspeed,

STMicroelectronics, Infineon Technologies, ROHM Semiconductor, ON Semiconductor, Mitsubishi

Electric, Fuji Electric, Renesas Electronics, Toshiba Corporation, Littelfuse, GeneSiC Semiconductor,

Microchip Technology, Vishay Intertechnology, Semikron Danfoss, Texas Instruments, Global Power

Technologies Group (GPTG), Power Integrations, Alpha & Omega Semiconductor, and Others.

What is the growth rate of the global silicon carbide power semiconductor market?

▾ The market is growing at a CAGR of 21.8 percent over the forecasted period.