Market Overview

The Global Silicone Elastomer Market is projected to reach

USD 9.3 billion in 2025 and grow at a compound annual growth rate of

7.7% from there until 2034 to reach a value of

USD 18.3 billion.

Silicone elastomers are flexible rubber-like materials made from silicone polymers. With superior heat resistance, flexibility, and durability, they find use across many industries. Produced by mixing silicone with additives and curing agents which form solid yet elastic structures. Their ability to withstand extreme temperatures, chemicals, UV exposure makes them suitable for automotive, healthcare, electronics and construction applications as they won't degrade as easily in demanding environments like natural rubber would.

Silicone elastomers have seen higher demand due to their superior properties. Automotive industries use them in gaskets, seals, and hoses subject to high heat and pressure healthcare facilities take advantage of biocompatibility for medical implants, tubing, and wearable devices electronics manufacturers rely on silicone elastomers as an insulating and protecting material for delicate components the construction industry uses them as coatings, adhesives, and sealants with weather resistance capabilities, further driving the market growth. As industries search for durable yet high-performance materials, markets for silicone elastomers are expected to expand significantly further over time.

Further, silicone elastomers include advances in manufacturing techniques, sustainability efforts, and customization options. Modern production methods are enhancing efficiency while decreasing waste; eco-friendly options like bio-based silicones and recyclable elastomers have gained prominence as industries strive for sustainable solutions customized silicones developed in various colors, hardness levels, and textures are also increasingly being produced to meet specific customer requirements. All these trends are shaping the future of silicone elastomers, making them even more widely used than before.

Over time, several events have had a profound effect on the silicone elastomer industry. For example, the pandemic caused increased demand for medical-grade silicone products such as respiratory masks and tubing from medical suppliers supply chain disruptions led to temporary shortages and price fluctuations as a result of supply chain interruptions technological advancements such as

3D printing with silicone elastomers opened new possibilities in product design and manufacturing while regulations related to environmental impact and safety standards played their role in shaping this sector of industry.

Silicone elastomers hold immense promise for future applications, with continued research and innovation driving their use. Scientists are exploring new methods of increasing the heat resistance, electrical conductivity, and biodegradability properties of silicone elastomers. With industries evolving further still, demand for advanced materials will prompt manufacturers to produce even superior versions. Introducing self-healing and temperature-sensitive silicones may further revolutionize their use.

Silicone elastomers have quickly become an indispensable component in numerous industries due to their durability, adaptability and adaptability. Their growth is spurred by growing demand in industries like automotive, healthcare, electronics and construction with emerging trends like sustainability, customization and new manufacturing techniques shaping its future and leading the industry into new frontiers of development - silicone elastomers will remain a fundamental element in modern technologies and everyday products for years to come.

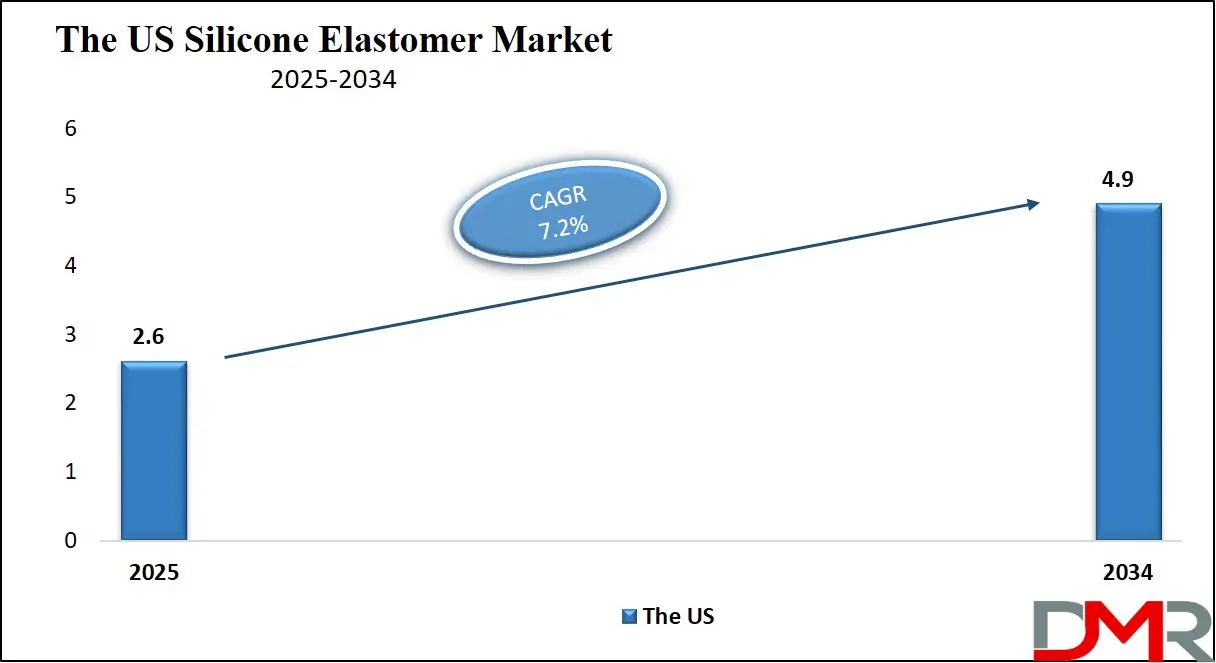

The US Silicone Elastomer Market

The US Silicone Elastomer Market is projected to reach USD 2.6 billion in 2025 at a compound annual growth rate of 7.2% over its forecast period.

The US has strong growth opportunities in the silicone elastomers market due to rising demand in the automotive, healthcare, and construction industries. Advanced manufacturing, growing infrastructure projects, and a growing medical sector drive demand for high-performance silicone materials. Innovation in electric vehicles, medical devices, and sustainable construction further boosts market expansion, creating significant opportunities for growth.

Further, the market is driven by strong demand from the automotive, healthcare, and construction industries, along with the development of electric vehicles and medical devices. The push for high-performance, durable materials in infrastructure and industrial applications further fuels growth. However, fluctuating raw material prices and stringent environmental regulations on silicone production act as restraints, potentially increasing costs and limiting market expansion in certain sectors.

ℹ

To learn more about this report –

Download Your Free Sample Report Here

Silicone Elastomer Market: Key Takeaways

- Market Growth: The Silicone Elastomer Market size is expected to grow by USD 8.2 billion, at a CAGR of 7.7%, during the forecasted period of 2026 to 2034.

- By Product: The LSR segment is anticipated to get the majority share of the Silicone Elastomer Market in 2025.

- By End User Industry: The construction segment is expected to get the largest revenue share in 2025 in the Silicone Elastomer Market.

- Regional Insight: Asia Pacific is expected to hold a 48.2% share of revenue in the Global Silicone Elastomer Market in 2025.

- Use Cases: Some of the use cases of Silicone Elastomer include medical device, construction & sealants, and more.

Silicone Elastomer Market: Use Cases

- Automotive Components: Utilized in gaskets, seals, and hoses to withstand extreme temperatures, pressure, and chemicals, ensuring durability in engines and exhaust systems.

- Medical Devices: Biocompatible silicone elastomers are utilized in implants, tubing, and wearable medical devices due to their flexibility, safety, and resistance to body fluids.

- Electronics & Electrical Insulation: Protects delicate components in smartphones, circuit boards, and connectors by offering thermal stability, moisture resistance, and electrical insulation.

- Construction & Sealants: Applied in adhesives, weatherproofing materials, and coatings to provide strong sealing, UV resistance, and longevity in buildings and infrastructure.

Market Dynamic

Driving Factors in the Silicone Elastomer Market

Rising Demand in Healthcare and Medical Applications

The growing use of silicone elastomers in the healthcare sector is a major growth driver. Their biocompatibility, flexibility, and resistance to extreme temperatures make them ideal for medical implants, prosthetics, and tubing. With developments in wearable medical devices and the growing aging population, the need for medical-grade silicone elastomers constantly grows. In addition, the recent pandemic accelerated the need for silicone-based medical equipment, further boosting market expansion.

Expanding Automotive and Electronics Sectors

The automotive industry depends on silicone elastomers for high-performance gaskets, seals, and hoses that can withstand extreme conditions. As electric vehicles (EVs) gain popularity, silicone elastomers are increasingly used in battery insulation and thermal management systems. Similarly, the electronics sector benefits from their superior electrical insulation and heat resistance in consumer gadgets and industrial equipment. The ongoing developments in miniaturization and high-performance electronics are further driving the demand for silicone elastomers in these industries.

Restraints in the Silicone Elastomer Market

High Production Costs and Raw Material Dependency

The manufacturing of silicone elastomers includes costly raw materials, like silicon metal and specialized additives, which contribute to high production costs. The dependence on a limited number of suppliers for these raw materials leads to price fluctuations and supply chain disruptions. Small and medium-sized manufacturers often struggle with the high investment demand for advanced production technologies. These cost-related challenges can slow market growth and limit the widespread adoption of silicone elastomers in price-sensitive industries.

Environmental Concerns and Regulatory Challenges

The non-biodegradable nature of traditional silicone elastomers creates environmental concerns, as disposal and recycling remain challenging. Stricter government regulations on chemical safety, emissions, and sustainability impact the production and use of silicone-based products. Compliance with evolving environmental standards increases operational costs for manufacturers, making it difficult for some companies to compete. In addition, regulatory restrictions on certain additives and curing agents can affect the formulation and performance of silicone elastomers, further posing challenges to market expansion.

Opportunities in the Silicone Elastomer Market

Growing Demand for Sustainable and Bio-Based Silicone Elastomers

With the growth in environmental concerns, there is a rising demand for eco-friendly and recyclable silicone elastomers. Research and development in bio-based silicone materials offer a significant opportunity for market growth. Companies investing in sustainable alternatives can attract environmentally conscious consumers and industries focused on reducing their carbon footprint. The shift toward greener materials in the automotive, healthcare, and construction sectors is expected to drive the adoption of innovative silicone elastomer solutions.

Expansion in Emerging Markets and Technological Advancements

Rapid industrialization and infrastructure development in emerging economies create new opportunities for silicone elastomers in various applications. Countries in Asia-Pacific, Latin America, and the Middle East are experiencing increased demand in the automotive, electronics, and medical sectors. In addition, developments such as 3D printing and smart silicone materials allow the production of customized and high-performance elastomers. These technological innovations open new possibilities for manufacturers to develop specialized products catering to evolving industry needs.

Trends in the Silicone Elastomer Market

Growing Demand for Sustainable and Bio-Based Silicone Elastomers

With the growth in environmental concerns, there is a growing demand for eco-friendly and recyclable silicone elastomers. Research and development in bio-based silicone materials offer a significant opportunity for market growth. Companies investing in sustainable alternatives can attract environmentally conscious consumers and industries focused on reducing their carbon footprint. The shift toward greener materials in the automotive, healthcare, and construction sectors is expected to drive the adoption of innovative silicone elastomer solutions.

Expansion in Emerging Markets and Technological Advancements

Rapid industrialization and infrastructure development in emerging economies create new opportunities for silicone elastomers in various applications. Countries in Asia-Pacific, Latin America, and the Middle East are experiencing increased demand in the automotive, electronics, and medical sectors. In addition, developments such as 3D printing and smart silicone materials allow the production of customized and high-performance elastomers. These technological innovations open new possibilities for manufacturers to develop specialized products catering to evolving industry needs.

Research Scope and Analysis

By Product Analysis

Liquid Silicone Rubber (LSR) is essential in driving growth in the silicone elastomers market and is set to lead the market in 2025, with a share of 58.9%. LSR is highly sought-after due to its durability, flexibility, and capacity to withstand extreme temperatures qualities that make it suitable for medical, automotive, and electronics applications. LSR's ability to be formed into complex shapes quickly and precisely supports manufacturers produce high-quality products at reduced costs, driving its popularity among industries seeking materials with both performance & efficiency in mind.

Its popularity continues to increase. LSR is used across industries, healthcare uses it for medical implants and devices, while automotive uses it to create reliable seals and gaskets. As technology progresses and industries expand, demand for LSR keeps growing as it drives expansion of the silicone elastomers market.

Further, Room-Temperature Vulcanizing (RTV) silicones are also becoming an integral component of the rapidly expanding silicone elastomers market and is expected to have the highest growth over the forecasted period. RTV silicones provide many advantages as they cure at room temperature without needing heat sources for curing purposes. Construction, electronics, and automotive industries all use them for sealing, bonding, and coating applications due to their strong resistance against moisture, chemicals, and extreme temperatures making them reliable long-term partners in production processes.

RTV silicones provide electronic protection while construction projects use them to seal joints and cracks effectively. RTV silicones continue to gain in popularity with industries as industries search for long-lasting materials with an easy application process their versatility and portability make them key components of an expanding silicone elastomers market.

By Process Analysis

Liquid Injection Molding (LIM) technology is a key factor driving silicone elastomers' market expansion, accounting for an expected 36.7% share in terms of revenue in 2025. LIM provides fast, precise, and high-volume production of silicone parts, ideal for industries like automotive, healthcare, and electronics. LIM guarantees consistent quality while reducing waste.

In addition, it makes production costs cheaper by automating its molding process. LIM is mainly used for developing medical devices, seals, gaskets, and other complex silicone components. As LIM produces parts with exceptional strength, flexibility, and heat resistance properties, industries prefer it for demanding applications. As manufacturers look for more affordable ways of producing high-performance silicone products like LIM continues to rise alongside market growth for silicone elastomers.

Moreover, Compression Molding is projected to be one of the fastest-growing processes within the silicone elastomers market during this forecast period, owing to mainly used as it is cost-effective, straightforward, and perfect for producing high-strength silicone parts with excellent heat and chemical resistance, popular across industries like automotive, aerospace, industrial as well as consumer products such as seals, gaskets, and insulation materials that need high-quality silicone seals, gaskets, or insulation materials. Compression molding's ability to efficiently manage both small and large production runs is driving its rapid expansion within an expanding silicone elastomers market.

By End User Industry Analysis

Construction will dominate the silicone elastomers market in 2025 with 41.1%, driving significant growth. Silicone elastomers are widely used in construction because of their durability, flexibility, resistance to extreme weather, moisture, chemical conditions, and resistance to extreme temperatures. Silicone elastomers are important in sealing, bonding, and insulation within buildings - helping improve energy efficiency and structural integrity while improving energy efficiency. Due to infrastructure projects, smart buildings, green construction and increased demand for high-performance materials like silicone elastomers is increasing exponentially.

Their use as window seals, expansion joints, coatings, and adhesives makes them popular choices with builders worldwide as construction activities expand globally this sector will have a key part in expanding the silicone elastomer market over time.

Further, Industrial machinery is projected to experience the fastest growth over the forecast period in terms of end-user industry market segment share for the silicone elastomers market during this timeframe. Silicone elastomers have become an indispensable material in machinery because of their excellent heat resistance, flexibility, and durability properties.

They enhance the performance of seals, gaskets, and vibration dampers to ensure smooth operation even under adverse conditions. With industries transformation toward efficiency and advanced manufacturing practices, demand for high-quality silicone components is on the rise. Silicone elastomers have become essential components in modern manufacturing machinery due to their ability to enhance machine reliability and extend machine lifespan - prompting rapid expansion in the industrial machinery market.

The Silicone Elastomer Market Report is segmented on the basis of the following:

By Product

- High-temperature Vulcanize (HTV)

- Room-temperature Vulcanize (RTV)

- Liquid Silicone Rubber (LSR)

- Industrial Grade

- Medical Grade

- Food Grade

By Process

- Extrusion

- Liquid Injection Molding

- Injection Molding

- Compression Molding

- Others

By End User Industry

- Electrical & Electronics

- Automotive & Transportation

- Industrial Machinery

- Consumer Goods

- Construction

- Others

Regional Analysis

Leading Region in the Silicone Elastomer Market

Asia Pacific is anticipated to dominate the silicone elastomers market by 2025, holding an anticipated share of

48.2%. Its strong growth can be due to rapid industrialization, urban development, and growth in demand from key industries like construction, automotive production, electronics production, and healthcare services.

Countries like China, India, and Japan are investing heavily in infrastructure projects and advanced manufacturing facilities, creating higher demand for high-performance materials such as silicone elastomers. Asia Pacific will remain the world's fastest-growing market for silicone elastomers with strong economic growth, technological developments, and increasing industrial activities, as it becomes the biggest and fastest-growing market for them.

Significant Growing Region in the Silicone Elastomer Market

The Middle East and Africa (MEA) region is projected to experience rapid expansion for silicone elastomers over the forecast period, driven by rapid urbanization, infrastructure expansion, and expanding industrial sectors that demand high-performance materials. Construction industries across MEA are experiencing rapid expansion with large-scale projects, necessitating durable silicone-based sealants and coatings for large projects.

Further, healthcare and automotive sectors in the region are increasing demand for silicone elastomers used in medical devices and vehicle components rising investments in energy sources including oil, gas, and renewable sources further drive market expansion. With growth in industrial activity and technological advancements expected throughout the MEA region, silicone elastomer market growth may see explosive expansion within the MEA region.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The silicone elastomers market is highly competitive, with many global and regional players competing for market share. Leading companies focus on innovation, product quality, and expanding their production capacities to meet rising demand. Key players include Dow Inc., Wacker Chemie AG, and Shin-Etsu Chemical Co., Ltd. They invest in R&D to create advanced silicone elastomers for industries like automotive, healthcare, and construction. Partnerships, mergers, and acquisitions are common strategies to strengthen market presence. As demand grows, competition will increase, driving more innovation and better product offerings.

Some of the prominent players in the Global Silicone Elastomer are:

- DoW Inc

- Wacker Chemie AG

- Momentive Performance Materials Inc.

- Shin-Etsu Chemical Co., Ltd.

- China National Bluestar (Group) Co., Ltd.

- KCC Corporation

- Elkem ASA

- Saint-Gobain

- Cabot Corporation

- Rogers Corporation

- Nusil Technology LLC

- Primasil Silicones Ltd.

- Wynca Group

- Hoshine Silicon Industry Co., Ltd.

- Dongyue Group Ltd.

- SIGMA SOFT

- ContiTech AG

- TechSil Ltd.

- The Rubber Company

- Silchem Inc.

- Other Key Players

Recent Developments

- In February 2025, Prism Worldwide and Sherwood Industries announced a partnership to revolutionize the extruded rubber industry by launching sustainable thermoplastic elastomers (TPEs). Designed as a high-performance and eco-friendly alternative to traditional rubber compounds, these advanced elastomers offer superior flexibility, durability, and recyclability. As industries transforms toward greener materials and circular economy solutions, this innovation aligns with global efforts to reduce plastic waste and carbon emissions.

- In November 2024, Elkem Silicones launched two new silicone elastomers, the AMSil 20503 series and the AMSil 92102 series, for 3D Printing applications. The AMSil 20503 series is based on customized liquid silicone rubber formulations. Developed for 3D printing, it supports the production of durable and functional components, like anatomical models and textiles. Owing to fine-tuned rheology, the products of this series boast better productivity, extended shelf life, high physicochemical performances, and durability.

- In November 2024, Teknor Apex unveiled the expansion of its medical-grade thermoplastic elastomer (TPE) portfolio with new grades specifically designed for biopharmaceutical tubing applications. Medical device manufacturers choose thermoplastic elastomers (TPEs) for applications that need flexibility or rubber-like elasticity, and they turn to Teknor Apex to deliver high-quality, regulatory-compliant Medalist® TPEs with a proven track record.

- In April 2023, DuPont introduced new low-cyclosiloxane silicone elastomer blends and silicone resin blends in response to growing consumer desires for products that address a range of troubling skin conditions. These new topical excipient blends also address the market's need to comply with transforming REACH regulatory compliance demands and to assist the shared commitment of DuPont and its customers to the United Nations Sustainable Development Goals (UN SDGs), mainly UNSDG No. 3.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 9.3 Bn |

| Forecast Value (2034) |

USD 18.1 Bn |

| CAGR (2025–2034) |

7.7% |

| Historical Data |

2019 – 2024 |

| The US Market Size (2025) |

USD 2.6 Bn |

| Forecast Data |

2025 – 2033 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors, etc. |

| Segments Covered |

By Product (High-temperature Vulcanize (HTV), Room-temperature Vulcanize (RTV), Liquid Silicone Rubber (LSR)), By Process (Extrusion, Liquid Injection Molding, Injection Molding, Compression Molding, Others), By End User Industry (Electrical & Electronics, Automotive & Transportation, Industrial Machinery, Consumer Goods, Construction, and Others) |

| Regional Coverage |

North America – US, Canada;

Europe – Germany, UK, France, Russia, Spain, Italy, Benelux, Nordic, Rest of Europe;

Asia-Pacific – China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC;

Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America;

Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, Rest of MEA

|

| Prominent Players |

DoW Inc, Wacker Chemie AG, Momentive Performance Materials Inc., Shin-Etsu Chemical Co., Ltd., China National Bluestar (Group) Co., Ltd., KCC Corporation, Elkem ASA, Saint-Gobain, Cabot Corporation, Rogers Corporation, Nusil Technology LLC, Primasil Silicones Ltd., Wynca Group, Hoshine Silicon Industry Co., Ltd., Dongyue Group Ltd., SIGMA SOFT, ContiTech AG, TechSil Ltd., The Rubber Company, Silchem Inc, and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user),

Multi-User License (Up to 5 Users), and

Corporate Use License (Unlimited User) along with free report customization equivalent to

0 analyst working days, 3 analysts working days, and 5 analysts working days respectively.

|

Frequently Asked Questions

How big is the Global Silicone Elastomer Market?

▾ The Global Silicone Elastomer Market size is expected to reach a value of USD 9.3 billion in 2025 and is expected to reach USD 18.1 billion by the end of 2034.

Which region accounted for the largest Global Silicone Elastomer Market?

▾ Asia Pacific is expected to have the largest market share in the Global Silicone Elastomer Market with a share of about 48.2% in 2025.

How big is the Silicone Elastomer Market in the US?

▾ The Silicone Elastomer Market in the US is expected to reach USD 2.6 billion in 2025.

Who are the key players in the Global Silicone Elastomer Market?

▾ Some of the major key players in the Global Silicone Elastomer Market are DoW Inc, Wacker Chemie AG, Elkem ASA, and others.

What is the growth rate in the Global Silicone Elastomer Market?

▾ The market is growing at a CAGR of 7.7 percent over the forecasted period.