Market Overview

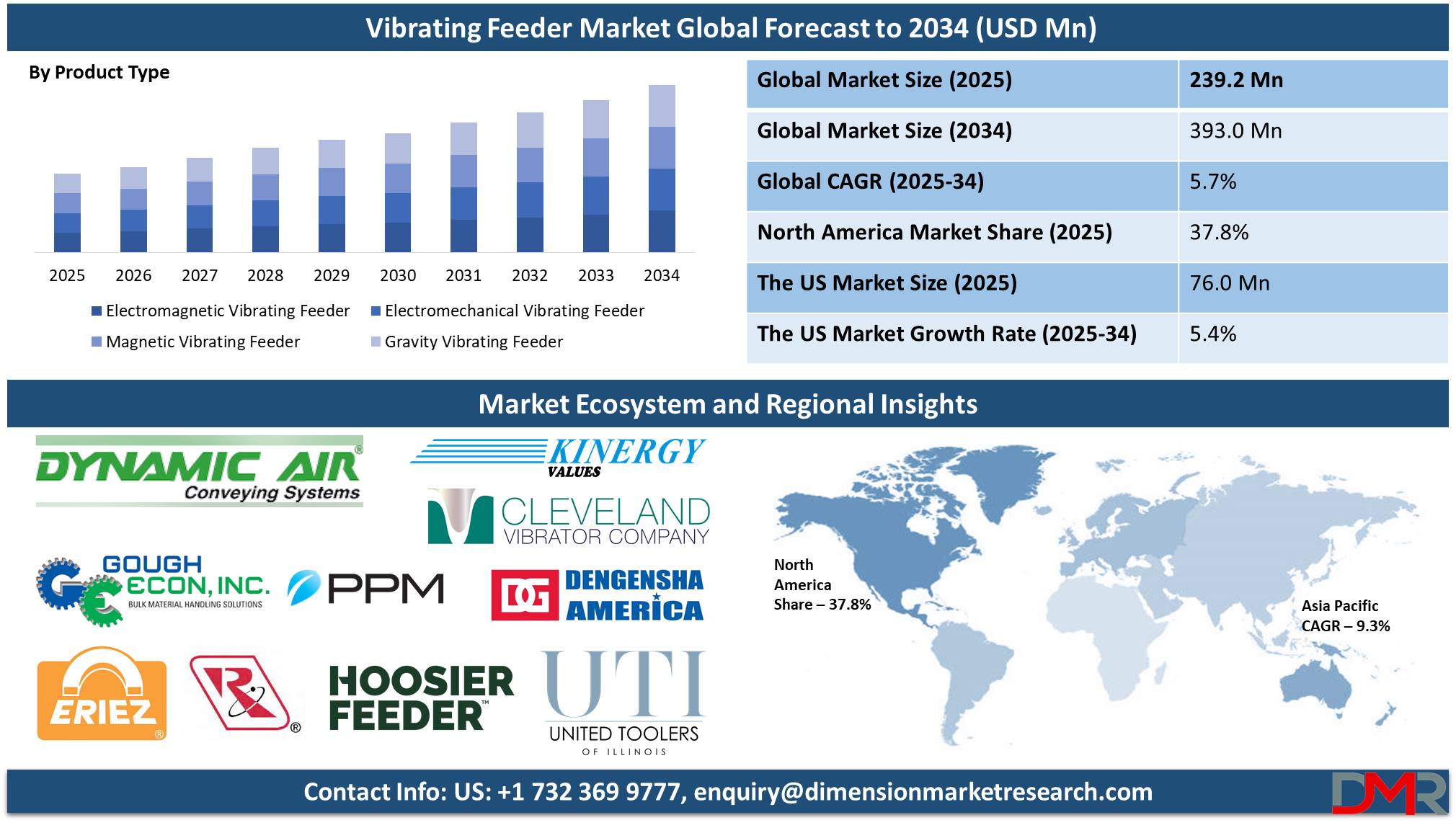

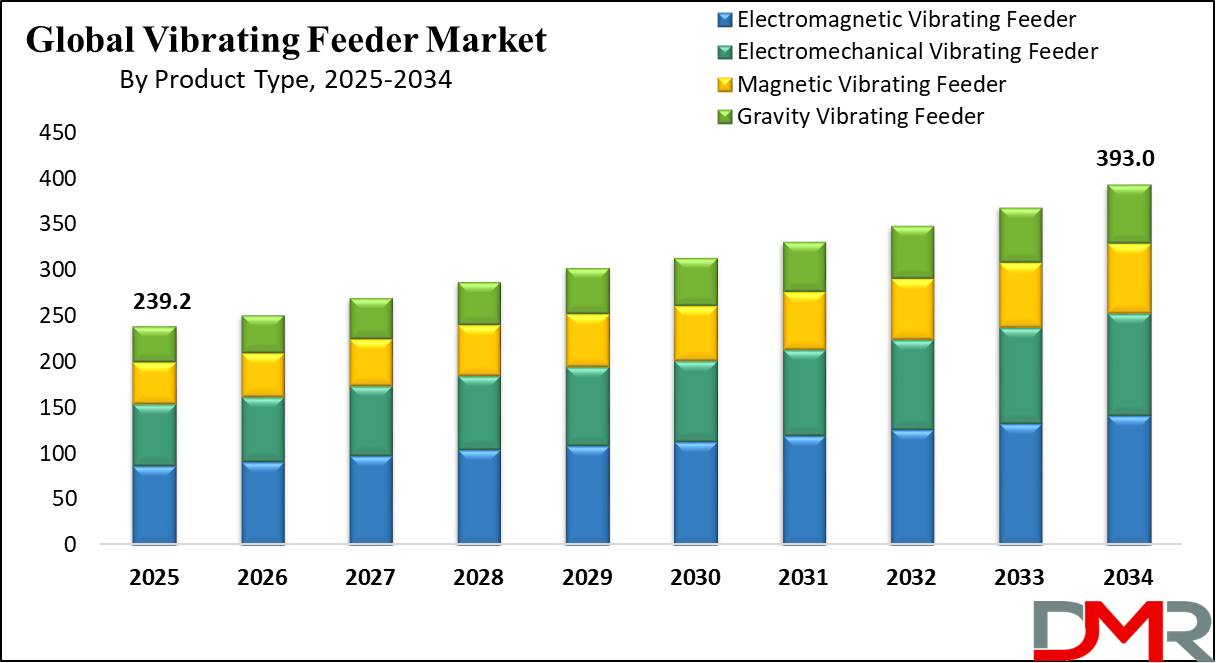

The Global

Vibrating Feeder Market size is expected to be valued at

USD 239.2 million in 2025, and it is further anticipated to reach a market value of

USD 393.0 million by 2034 at a

CAGR of 5.7%.

The global vibrating feeder market is growing steadily with a growing need for automation in sectors such as mining, construction, pharmaceuticals, and food processing driving demand. With efficient conveyance of materials, these feeders are increasingly adopted with a value-added of enhanced productivity and reduced manpower cost for manual handling. Energy efficiency and reduced maintenance requirements are driving demand for new product development, and electromagnetic and electromechanical vibrating feeders have become a reality. Emerging economies in Asia-Pacific, such as China and India, are witnessing growing demand with increased industrial activity. On a technological basis, IoT-powered feeders have become increasingly in demand, with real-time tracking and predictive maintenance capabilities.

The demand for vibrating feeders is increasing with increased automation in processing and material handling industries. With the increased use of AI sorters and AI-powered feeders, a new opportunity for manufacturers is emerging. With the increased use of recycling programs in most nations, an opportunity for vibrating feeders with the ability to process a variety of materials such as metal and plastic scrappings is emerging in the market. With increased growth in the food and beverage industry, with a demand for accuracy in ingredient feeding, the demand for vibrating feeders in the market is emerging. With the increased use of smart factories and 4.0 technology, demand for high-tech feeders with capabilities such as removability and adaptability is emerging.

Although it is a positive development path, its development is inhibited through certain restrictions like high installation costs and demand for experienced operators inhibit its application in small and medium companies. Besides, maintenance and downtime in operations become an issue for industries with continuous production demand. Stringent regulative requirements for sound and level of vibration, in developed nations in general, can restrict the use of specific types of feeders. Varying raw material prices, such as that of steel and copper, can impact production costs, and subsequently, impact the pricing strategies of companies in its case. The presence of alternative technology, such as belt conveyors and pneumatic conveying, is a competitive issue in its case.

The 2025 Global Vibrating Feeder Report is a comprehensive analysis of the market, including in-depth details about market size, growth opportunities, and future growth trends over the forecasting period. The report introduces an in-depth analysis of segments, with a segmentation of the market in terms of feeder, drive mechanism, application, end-user industry, and demand in regions, offering a strategic outlook of market trends.

The most important companies in the competitive scenario include Carman Industries, Eriez Manufacturing Co., Syntron Material Handling, Carrier Vibrating Equipment, Inc., Vibra Screw Inc., and General Kinematics Corporation. Quantitative and qualitative factors such as gross margin analysis, technological trends, and industry trends are examined in the report in an evaluation of competitiveness, and such factors can allow blue ocean market opportunity in the field of material handling and automation to be calculated for stakeholders.

Moreover, the report covers mergers, acquisitions, and alliances that shape the vibrating feeder market. Recent deals, such as a collaboration between Eriez Manufacturing Co. and an automation technology vendor for developing IoT-enriched vibrating feeders, reveal a growing focus on predictive maintenance and smart material flow options. In a similar manner, a collaboration between Carrier Vibrating Equipment, Inc., and a European producer of vibrating equipment shows expansion in geographies outside its current location.

Based on a strong emphasis laid on market opportunity and challenge, this report is a critical handbook for new entrants and operators, providing a strategic analysis of emerging trends, technological breakthroughs, and ecologically friendly product innovation in the global vibrating feeder market.

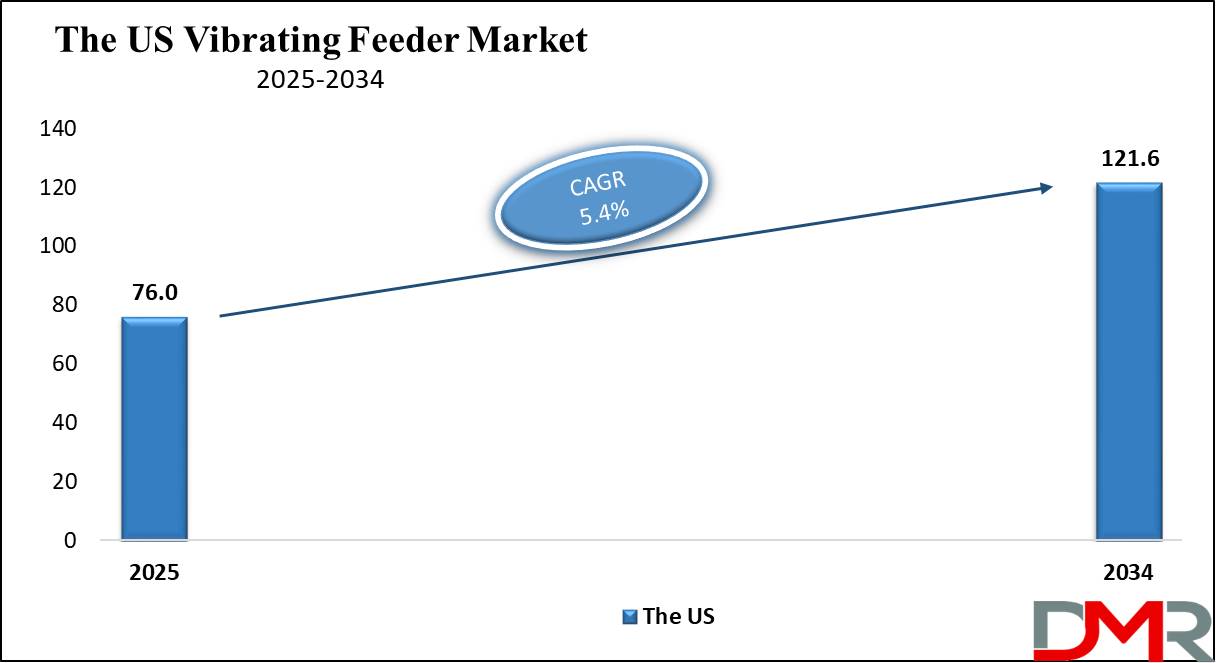

The US Vibrating Feeder Market

The US Vibrating Feeder Market is projected to be valued at USD 76.0 million in 2025. It is expected to witness subsequent growth in the upcoming period as it holds USD 121.6 million in 2034 at a CAGR of 5.4%.

The demand for automation and material handling gear in industries such as mining, construction, food processing, and manufacturing is high in the US vibrating feeder market. High demand for such gear in these industries is fueled by America’s strong base of industries, technological development, and strong infrastructure development in the country. High demand for smart manufacturing solutions and Industry 4.0 technology is driving demand for sophisticated vibrating feeders with real-time tracking and automation capabilities.

The presence of key producers and providers, together with increased investments in infrastructure development, triggers expansion in the market. High consumption of automation technology and a qualified workforce form a demographic advantage, strengthening market potential even further. Industries, with a view towards sustainability, transition towards low-maintenance and efficient vibratory feeders in compliance with regulative standards. Government actions in supporting domestic production and mining operations stimulate expansion in the market.

The expansion of the market is not only spurred by increased demand in the food and pharmaceutical sectors, in which purity and accuracy count, but also in the US, a key player in the global vibrating feeder market, with continuous innovation and strategic partnerships shaping its future direction.

Global Vibrating Feeder Market: Key Takeaways

- Global Market Value: The Global Vibrating Feeder Market size is estimated to have a value of USD 239.2 million in 2025 and is expected to reach USD 393.0 million by the end of 2034.

- The US Market Value: The US- US-vibrating feeder Market is projected to be valued at USD 76.0 million in 2025. It is expected to witness subsequent growth in the upcoming period as it holds USD 121.6 million in 2035 at a CAGR of 5.4%.

- Regional Analysis: North America is expected to have the largest market share in the Global Vibrating Feeder Market with a share of about 37.8% in 2024.

- Key Players: Some of the major key players in the Global Vibrating Feeder Market are Eriez, Rodix Inc., PPM Technologies Holdings LLC, United Toolers of IL, Jerhen-Warren Industries Inc., Hoosier Feeder Company, Vibratory Feeders Inc., and many others.

- Global Market Growth Rate: The market is growing at a CAGR of 5.7 percent over the forecasted period.

Global Vibrating Feeder Market: Use Cases

- Mining and Aggregates: Vibrating feeders are used to transport and screen bulk materials such as ores, coal, and crushed rock in mining and quarrying operations, enhancing productivity and material handling efficiency.

- Food processing: In processing foods, vibrating feeders assure dosing accuracy in ingredients, uniformity in raw materials feeding, and unobstructed flow of materials, allowing for added consistency and productivity in production lines.

- Pharmaceutical Industry: Vibration feeders allow for safe and controlled motion of small parts, granulates, and powder in pharmaceutical processing, with increased automation, reduced loss, and correct dosing mixtures.

- Recycling Sector: Vibration feeders play a significant part in garbage disposal through efficient sortation and routing of numerous recyclables such as metal, plastic, and glass for secondary processing and reuse.

Global Vibrating Feeder Market Dynamic

Driving Factors in the Global Vibrating Feeder Market

Rising Industrial Automation and Smart Manufacturing AdoptionThe global move towards industrial automation is contributing a lot to the heightened demand for vibrating feeders. Mining, construction, food processing, and pharmaceutical sectors rely on computerized processes for material handling for increased efficiency, reduced manpower, and fewer faults in operations. Automated processes cannot work effectively in the absence of vibrating feeders, as these allow bulk materials to move with minimum intervention and in a precisely controlled manner. With the growing use of smart manufacturing and Industry 4.0 technology, demand for robotic systems, conveyors, and AI-powered machinery-integrate able feeders grew manifold.

Smooth flow of materials at constant flow rates, reduced bottleneck in production, and overall efficiency in processes can be attained through automation. Industries have a growing interest in precision feeding technology, capable of processing a variety of materials such as powder, granule, and aggregates, with zero spillage and no deterioration in materials. With companies investing increasingly in automation, demand for sophisticated vibrating feeders will go through a sharp rise in demand.

Expanding Mining and Construction Sectors

The mining and construction industries are two of the largest industries utilizing vibrating feeders, and ongoing expansion in these industries is one of the key drivers for the market. In mining, vibrating feeders have a significant role in conveying bulk materials such as iron ore, coal, limestone, and other ores from bins to crushers and screens. Mining activity, fueled by growing demand for raw materials, spurred by infrastructure development and industrialization, is driving demand worldwide. Similarly, in the construction industry, vibrating feeders function to convey aggregates, sand, cement, and other construction materials, and enable efficient operations in factories for production.

Large-scale infrastructure development, such as roads, highways, and smart city development, is driving demand for efficient material handling even more. Emerging economy governments are investing big in infrastructure development, providing a rich opportunity for producers of vibrating feeders. Besides, technological improvements in feeders, such as custom settings for specific kinds of materials and automatic controls for feeding, are driving demand for such a system even in the mining and construction industries.

Restraints in the Global Vibrating Feeder Market

High Initial Investment and Maintenance Costs

Although vibrating feeders have numerous efficiency and automation strengths, high initial costs form a significant barrier to use, particularly for SMEs. High-tech, smart technology, AI-powered, high-capacity handing vibratory feeders require high installation, calibration, and training costs. Not only must maintenance regularly occur for them to work at an ideal level, but wear-and-tear parts such as vibratory motors, springs, and trays can drive operational costs even higher when replaced.

For companies with a tight budget, such factors make alternative options for conveying materials, such as belt conveyors and pneumatic conveying, a preferable alternative. To counteract such, producers strive to make cost-effective model feeders with modular constructions that allow for simple maintenance and upgrades, becoming accessible to a larger range of industries.

Regulatory Challenges and Environmental Concerns

Stringent regulating requirements for environmental impact, workplace safety, and noise pollution challenge producers of vibrating feeders. Most developed nations' regulating agencies, such as the European Machinery Directive and OSHA (Occupational Safety and Health Administration), have high requirements for machines in industries to mitigate workplace danger and minimize environmental footprints. Heavy industries' operations with vibrating feeders have to comply with restrictions in terms of vibrational level and noise, for which investments in sound-absorbing technology and frame redesigns can become a necessity.

Environmental concerns in terms of excessive vibrational impact in adjacent equipment, buildings, and surrounding environments can restrict use in certain processes. Non-conformity with compliance requirements can make companies suffer legal penalties and additional costs in terms of redesigns. To counter such obstacles, producers have been investing in development and research to produce low-noise, efficient, and environmentally friendly vibratory feeders that comply with regulating requirements worldwide and yet have high performance and dependability.

Opportunities in the Global Vibrating Feeder Market

Increasing Applications in the Recycling Industry

The increased demand for circular economy and waste management programs has unlocked new opportunities for vibrating feeders in the recycling sector. Industries and governments have begun imposing stricter controls over disposal, and, in return, demand for high-tech material processing and sortation is emerging. In a recycling unit, vibrating feeders have a critical role in conveying, sortation, and screening recyclables such as metal, plastics, glass, and electronic trash. These feeders precisely deliver materials in an even manner and sort them according to suitability for secondary processing.

There will be an increased demand for efficient processing of mixed and lightweight materials, and, therefore, development in technology will arise in terms of design. Innovation in vibration technology, such as variable frequency drives (VFDs), will allow for effective amplitude and velocity control over a feeder, and, therefore, accuracy in sortation will be enhanced. With an increased concern for sustainability in general, expansion in the recycling industry will become a key opportunity for growing vibrating feeder manufacturers.

Expansion in Emerging Markets and Untapped Regions

The Asia-Pacific, Latin America, and African nations' emerging economies are growing at a high growth rate, and with them, new channels for vibrating feeder companies have opened up. As industries in these nations such as manufacturing, mining, and construction develop, efficient and cost-effective material handling solutions become an increasingly growing necessity. Developing nations are investing in infrastructure development, industrial automation, and raw material extraction, and in the bargain, demand for vibrating feeders is growing. In these nations, food processing and pharmaceutical industries are emerging, and with them, demand for high-tech sophisticated feeders for high-precision handing of materials is emerging.

Players in the market can gain a strong presence in these emerging economies through localized offerings, alliances, and post-sales service offerings. Developing country governments are supporting indigenization and domestic industries, driving demand for technology-intensive and competitively priced feeder offerings, and even for industrial automation technology, including vibrating feeders, even more. Players entering these unpenetrated markets with competitively priced and technology-intensive feeder offerings will have a competitive edge in the market.

Trends in the Global Vibrating Feeder Market

Integration of Smart Technologies and IoT-enabled Feeders

The industrial sector is undergoing a full-fledged transformation, with smart technology at its driving seat, and efficiency and productivity at its heart. IoT-powered vibrating feeders are becoming increasingly adopted, with real-time tracking, automatic controls, and predictive maintenance in store for them. Embedded sensors in feeders can track vibration frequency, loading capacity, and consumption, and operators can remotely adjust performance for best efficiency. Not only do smart feeders save downtime, but operations become safer with fewer intervention requirements for humans.

AI-powered feeders can even modify settings in relation to behavior in terms of material flow, providing accuracy in feeding and minimizing wastage to a minimum. With the increased use of digital twin technology, producers can build virtual replicas of their networks of feeders and simulate performance, detect faults in advance, and tune settings for best efficiency. As industries go towards automation and fact-based decision-making, smart vibrating feeders will gain increased use in years to come.

Growing Demand for Energy-efficient and Eco-friendly Feeders

Higher Demand for Energy-saving and Environment-friendly Feeders Energy efficiency is a new concern for industries worldwide, and demand for efficient vibratory feeders is escalating in reaction. Traditional feeders consume a lot of energy, with high operational costs and a larger environmental footprint for industries. To counteract, companies develop optimized-vibration technology feeders, with reduced energy consumption and high throughput output. Electric-powered feeders, with reduced consumption compared to pneumatic and mechanical ones, are becoming increasingly common in industries with strong environmental legislation in practice.

Besides, recycled and lighter materials for the construction of feeders are becoming common, with reduced environmental footprints for industries. Industries and governments' stricter environment policies have encouraged companies to integrate noise and vibration suppression technology in feeders, in compliance with workplace environment requirements. With governments and industries imposing stricter environment-related policies, future trends for efficient and environment-conscious feeders will drive innovation and growth in the market.

Research Scope and Analysis

By Product Type

Electromagnetic vibratory feeders have a strong presence in the global vibratory feeder market with high efficiency, accuracy, and versatility in a range of industries. Unlike mechanically operated feeders, electromagnetic feeders use electromagnetic power to generate measured vibratory motion, offering high accuracy in conveying materials. Thus, electromagnetic vibratory feeders have become a first choice in high-accuracy industries such as chemicals, food processing, and pharmaceuticals. With high efficiency in processing fine powder, granulates, and bulk solids, electromagnetic vibratory feeders have a significant advantage over traditional feeders.

One of the most important factors in their success is efficiency in terms of energy use. Electromagnetic feeders use less power when compared to electromechanical ones, and therefore, they are more environmentally friendly and less costly in terms of long-term use. In addition, electromagnetic feeders have a high level of control, and operators can precisely vary the feed rate in relation to production requirements. In industries such as mining and metallurgy, such adaptability is important in terms of controlling the flow of materials in a manner that will not cause any bottlenecking or overfeeding.

Another reason for them being in high demand is that less maintenance is involved. There are fewer moving parts in electromagnetic feeders, less wear and tear, less maintenance and replacement work, and less generated noise and vibration, and in compliance with workplace security and legislative standards, particularly in developed nations with high standards for controlling noise pollution.

Increased automation in industries is creating a growing demand for IoT-enabled smart feeders. Electromagnetic vibratory feeders can integrate with new controls with ease, and real-time tracking and remote access can be supported through them. With industries becoming increasingly efficiency-, accuracy-, and environment-conscious in conveying materials, its dominant position in the market will not change anytime soon in the upcoming period.

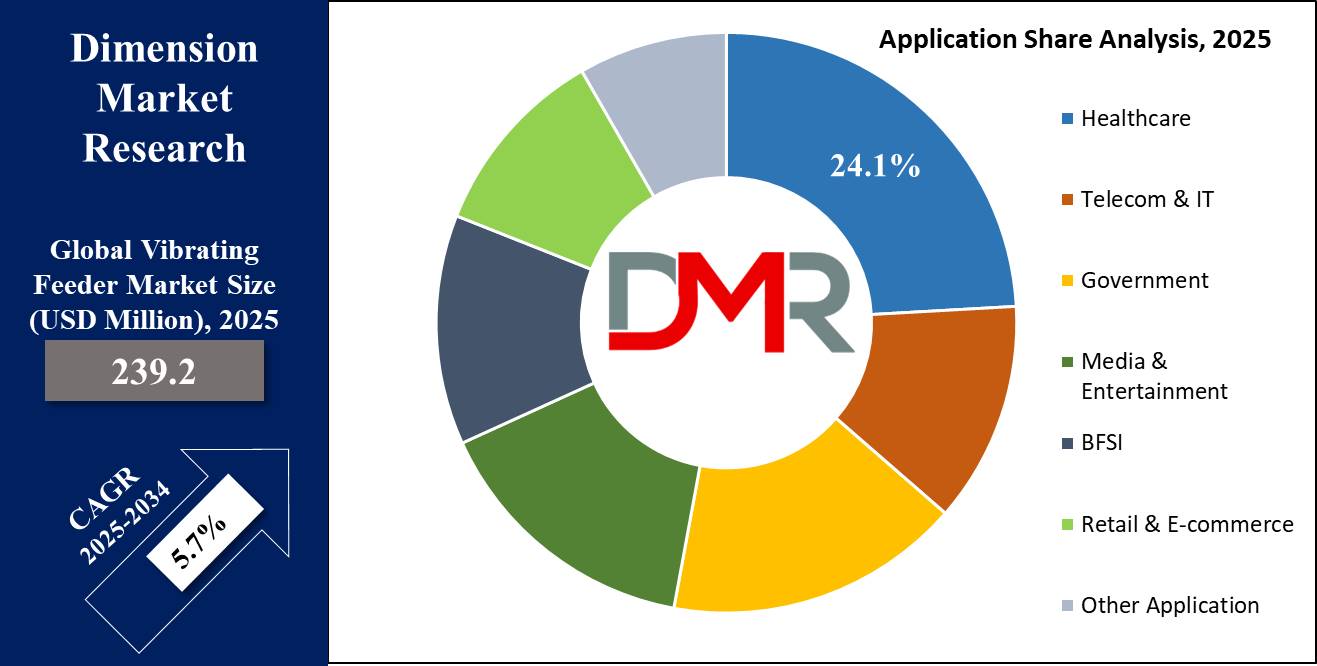

By Application

The automotive industry is projected to dominate the vibrating feeder market with its high degree of autonomy, high-tech production processes, high accuracy, and constant feeding demand for materials. Automotive manufacturing involves assembling numerous small and large parts, such as nuts and bolts and large metal plates, and vibrating feeders play an important role in moving and positioning such materials with ease and efficiency. The application of automation and robots in the field has increased high-performance feeders' value in blending in with production lines effortlessly.

One of the most important factors in its prominence is its high-rate production environment. Auto companies have enormous factories with high production volumes, and in such a case, efficient and continuous material conveying is a necessity in a bid to maintain productivity. Vibratory feeders provide a continuous and constant flow of materials to robotic manipulators, conveyors, and assembly machines, reducing manpower and downtime. Precision in such a case is even critical in computerized welding, stamping, and machining operations, in which any deviation in supplying materials will result in defects and even shut down production altogether.

A driving demand for its application is the automotive demand for lightweight and high-precision engineering materials. With increased demand for fuel-saving and electric cars, car companies increasingly depend on aluminum, composite, and high-tech alloys for cars. There is an increased demand for vibrating feeders for conveying such lightweight but delicate materials, safeguarding them during transportation, and delivering them precisely to assembly lines. There is an increased demand for batteries and automotive parts for electric cars, and for efficient lithium, copper, and other raw materials for battery production, and for transporting them effectively.

The automotive sector keeps embracing smart manufacturing, Industry 4.0, and AI-facilitated production, and with it, smart vibrating feeders with IoT will become even more important. With a potential for heightened efficiency, accuracy, and automation, vibrating feeders become an imperative in automotive production, and with it, its position in its respective market will become even stronger.

The Vibrating Feeder Market Report is segmented on the basis of the following

By Product Type

- Electromagnetic Vibrating Feeder

- Electromechanical Vibrating Feeder

- Magnetic Vibrating Feeder

- Gravity Vibrating Feeder

By Application

- Automotive

- Electronic

- Food Processing

- Pharmaceutical

- Packaging

- Metal Working

- Other Application

Regional Analysis

North America is projected to dominate the global vibratory feeder market as it commands over

37.8% of the total revenue by the end of 2025. North America's vibratory feeder market is dominated, partially, by its developed base of industries and high application of automation technology. North America's powerful base of industries such as automotive, aeronautics, and consumer goods rely almost exclusively on efficient conveying of materials to produce in high volumes and high quality, and vibratory feeders make an integral part of such computerized processes, allowing for high accuracy and uniformity in conveying of materials, a necessity for high efficiency and cost savings in production processes. North America's powerful industries have emphasized a lot in terms of automation and technology, and therefore, a high demand for high-tech vibratory feeder systems in North America can be seen.

Also, high investments in mining and construction operations in the region make it a key player in the market. There are widespread mining operations in the United States and Canada, and a range of minerals and materials are extracted from them. Vibration feeders in such operations serve a key purpose in allowing bulk materials to be fed in a controlled manner into processing machines, enhancing productivity and efficiency in operations. In construction, the application of vibratory feeders in processes for material handling aids in big infrastructure development, and such factors contribute to driving the market even further.

Moreover, North America's technological innovation and orientation towards research and development drive the continued development of technology in vibratory feeders. With its dominant companies and strong infrastructure for goods and service supplying, access to high-tech goods and services is guaranteed, servicing a range of industries with its diversity in demand requirements, underpinned in an environment of innovation and strong industrious support, undergirding North America's dominant position in the global vibrating feeder market.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

The global vibrating feeder market is characterized by a group of dominant key companies competing with one another in terms of new product development, collaborations, and expansion in new geographies in a bid to enhance their position in the market. Established companies such as Eriez Manufacturing Co., General Kinematics Corporation, and Carrier Vibrating Equipment, Inc., have acquired strong positions in the market with a variety of vibrating feeders for a variety of industries. The companies attempt to introduce new and emerging technology, such as automation and IoT, in offerings in a move to respond to changing requirements in target industries.

Aside from these traditional companies, new entrants in terms of new companies with new offerings and new entrants with new technology and new capabilities, with a gamble at riding the increased demand for efficient material handling, have entered the market. With new offerings, new technology, and new capabilities, new entrants have begun competing with traditional companies in terms of providing new and newly added capabilities, such as new efficiency and accuracy in terms of moving and controlling materials, in a gamble at differentiation in a competitive market.

Some of the prominent players in the Global Vibrating Feeder Market are

- Eriez

- Rodix Inc.

- PPM Technologies Holdings, LLC

- United Toolers of IL

- Jerhen-Warren Industries, Inc.

- Hoosier Feeder Company

- Vibratory Feeders Inc.

- Cleveland Vibrator Company

- Dengensha America Corp.

- Design Tool, Inc.

- Dynamic Air Inc.

- Gough Econ, Inc.

- Kinergy Corporation

- Other Key Players

Recent Developments

- December 2024: Eriez Manufacturing Co. announced a strategic partnership with Siemens, a leading automation solutions provider, to develop advanced vibrating feeders with integrated IoT capabilities. This collaboration aims to enhance real-time monitoring, predictive maintenance, and overall operational efficiency, leveraging Siemens' expertise in industrial automation and digital transformation.

- November 2024: General Kinematics Corporation unveiled its latest line of energy-efficient vibrating feeders at the International Material Handling Exhibition in Las Vegas. These feeders incorporate advanced vibration control technology and lightweight, high-durability materials, designed to reduce operational costs and environmental impact.

- October 2024: Carrier Vibrating Equipment, Inc. completed the acquisition of Vibroprocess S.r.l., a well-established European manufacturer specializing in custom vibrating equipment. This strategic acquisition allows Carrier to expand its product portfolio, strengthen its market presence in Europe, and enhance its R&D capabilities for developing innovative material handling solutions.

- September 2024: The Global Material Handling Conference held in Chicago featured multiple sessions on advancements in vibrating feeder technology. Keynote speakers from companies like Syntron Material Handling, Cleveland Vibrator Company, and AViTEQ Vibrationstechnik GmbH discussed trends such as automation integration, smart sensors, and energy efficiency improvements in material handling applications.

- August 2024: A venture capital firm, Industrial Growth Partners, made a significant investment in Vibratory Solutions Inc., a startup specializing in smart vibrating feeders with AI-driven process optimization. This investment signals growing interest in the development of technologically advanced material handling solutions that improve efficiency and predictive maintenance capabilities.

- July 2024: A collaborative research initiative was launched between the Massachusetts Institute of Technology (MIT), Hoosier Feeder Company, and Rodix Inc. to explore new materials and designs for vibrating feeders. The goal is to develop lightweight, high-strength alloys and composite materials that enhance durability, efficiency, and adaptability in industrial applications.

- June 2024: An international expo in Germany, the Hannover Messe, showcased emerging technologies in the vibrating feeder market. Companies like Tarnos S.A., Carrier Europe, and Gough Econ presented their latest products, featuring innovations in digital control systems, energy efficiency, and modular designs that allow for easier customization and integration with smart manufacturing systems.

- May 2024: A merger between two mid-sized vibrating feeder manufacturers, ACTION Vibratory Equipment and General Kinematics Europe, was announced. The merger aims to combine technical expertise, expand global distribution channels, and create a more comprehensive product portfolio to meet the growing demands of the material handling industry.

- April 2024: Industry reports highlighted a surge in investments toward the development of eco-friendly vibrating feeders. Companies like Martin Engineering and Eriez have been focusing on reducing power consumption, using sustainable materials, and improving recyclability, reflecting a broader trend toward sustainability in industrial equipment manufacturing.

Report Details

| Report Characteristics |

| Market Size (2024) |

USD 239.2 Mn |

| Forecast Value (2033) |

USD 393.0 Mn |

| CAGR (2024-2033) |

5.7% |

| Historical Data |

2018 – 2023 |

| The US Market Size (2024) |

USD 76.0 Mn |

| Forecast Data |

2025 – 2033 |

| Base Year |

2023 |

| Estimate Year |

2024 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Product Type (Electromagnetic Vibrating Feeder, Electromechanical Vibrating Feeder, Magnetic Vibrating Feeder, and Gravity Vibrating Feeders), By Application (Automotive, Electronics, Food Processing, Pharmaceuticals, Packaging, Metal Working, and Others) |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia- Pacific– China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA

|

| Prominent Players |

Eriez, Rodix Inc., PPM Technologies Holdings LLC, United Toolers of IL, Jerhen-Warren Industries Inc., Hoosier Feeder Company, Vibratory Feeders Inc., Cleveland Vibrator Company, Dengensha America Corp., Design Tool Inc., Dynamic Air Inc., Gough Econ Inc., and Kinergy Corporation, and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users) and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |

Frequently Asked Questions

The Global Vibrating Feeder Market size is estimated to have a value of USD 239.2 million in 2025 and is expected to reach USD 393.0 million by the end of 2034.

The US- Vibrating Feeder Market is projected to be valued at USD 76.0 million in 2025. It is expected to witness subsequent growth in the upcoming period as it holds USD 121.6 million in 2035 at a CAGR of 5.4%.

North America is expected to have the largest market share in the Global Vibrating Feeder Market with a share of about 37.8% in 2024.

Some of the major key players in the Global Vibrating Feeder Market are Eriez, Rodix Inc., PPM Technologies Holdings LLC, United Toolers of IL, Jerhen-Warren Industries Inc., Hoosier Feeder Company, Vibratory Feeders Inc., and many others.

The market is growing at a CAGR of 5.7 percent over the forecasted period.