Market Overview

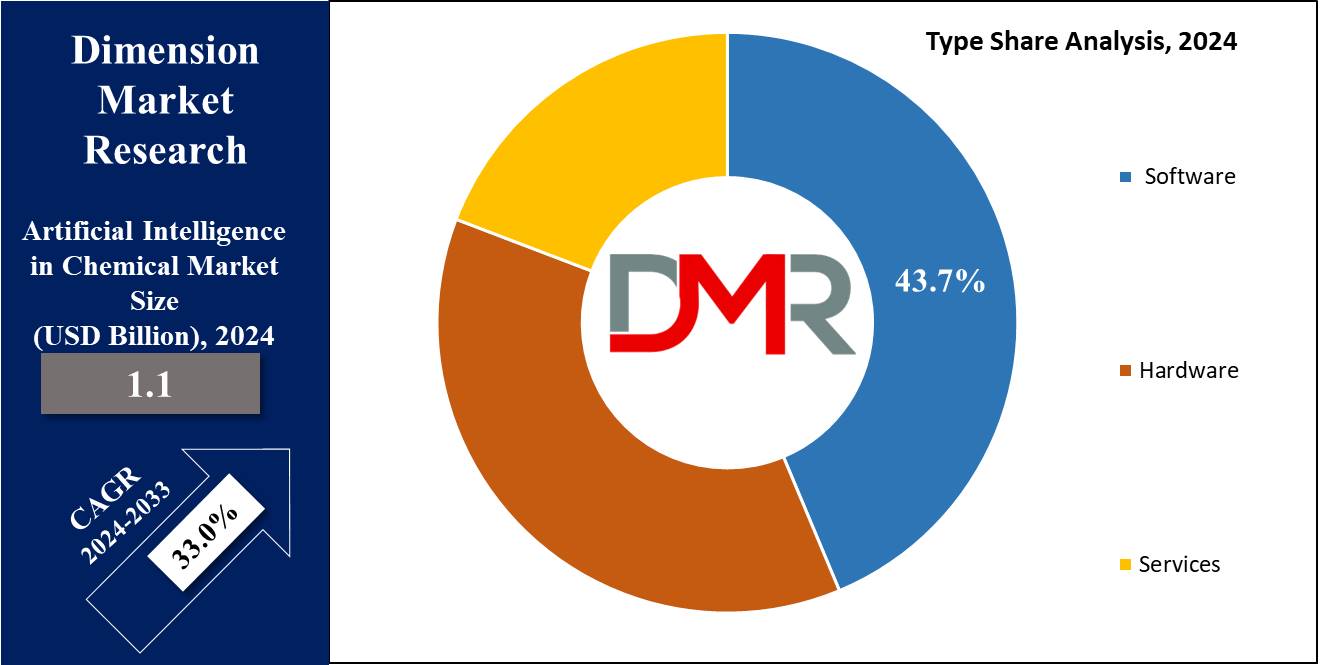

Global Artificial Intelligence (AI ) in Chemical Market size is expected to reach

USD 1.1 billion in 2024 and is further anticipated to value

USD 14.9 billion by 2033, at a CAGR of 33.0%.

Artificial Intelligence in chemicals is the process involving the application of computational techniques to understand, predict, & optimize chemical processes and materials. It helps analyze vast datasets, simulate molecular interactions, & design novel compounds with specific properties. There are wide applications of AI in chemistry in various domains, like drug discovery in materials science, environmental sustainability, and process optimization. The adoption of AI in chemistry allows researchers to accelerate the drug development process by identifying potential candidates with desired therapeutic effects while reducing costs & experimental errors.

Rising demand for reliable manufacturing processes & the adoption of modern digital methods by the chemical industry, along with an increasing interest in improved batch production scheduling & awareness of AI solutions, are driving the expansion of AI in chemical market. Huge government spending in research & development to optimize manufacturing processes is set to boost the adoption of AI in the chemical industry. AI-powered analytics are enabling chemical businesses to base their decisions on data which leads to reduced costs & improved efficiency.

Key Takeaways

- Market size: The global AI in chemical market size is expected to grow by 13.4 billion, at a CAGR of 33.0 % during the forecasted period of 2025 to 2033.

- Market Definition: AI in chemicals is the process of using AI algorithms for various processes and tasks within the chemical industry.

- Type Analysis: The software segment is forecasted to hold the largest market share of 43.7 % and dominate the AI in chemical market based on type in 2024.

- Technology Analysis: Machine learning is projected to be the dominant force in the market based on technology capturing the largest revenue share in 2024.

- Application Analysis: Discovery of new materials as an application is expected to witness significant growth with the highest revenue share throughout the forecast period.

- End User Analysis: Base Chemicals & Petrochemicals is forecasted to hold the largest market share of 33.2 % and dominate the AI in chemical market based on end-users in 2024.

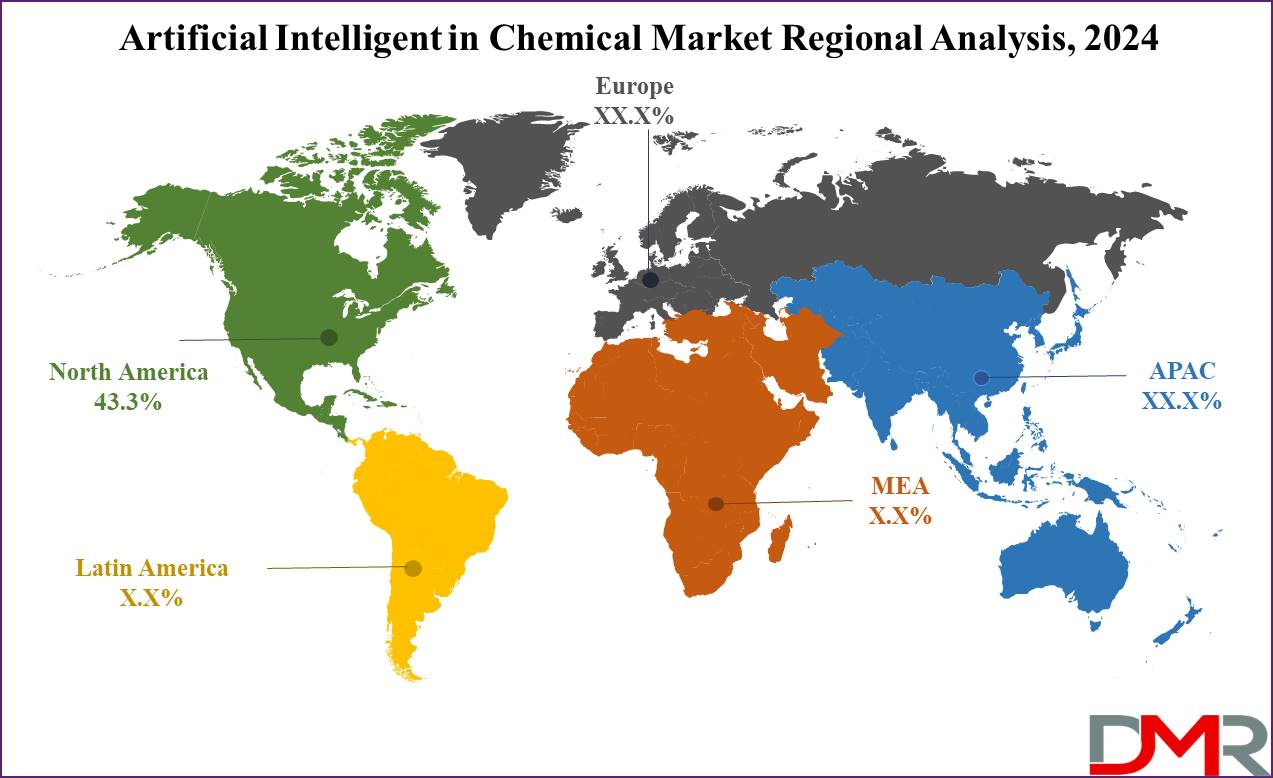

- Regional Analysis: North America is anticipated to dominate the AI in chemical market, capturing a revenue share of 43.3 % in 2024.

Use Cases

- Quality Control: By analyzing sensor data and detecting deviations from desired specifications, AI systems can monitor and control product quality in real time which ensures consistency and minimizes defects.

- Supply Chain Optimization: Ai is capable of optimizing supply chains by predicting demand, managing inventory, and identifying opportunities for cost savings and efficiency improvements.

- Process Control and Automation: Advanced algorithms are used to control and automate complex chemical processes, adjusting parameters in real time to maintain optimal conditions and maximize productivity.

- Drug Discovery and Development: It helps accelerate the drug discovery process by predicting molecular structures, identifying potential drug candidates, and simulating their interactions.

Market Dynamic

Drivers

Automation in the Chemical market:AI tools are extensively used to carry out tasks like identifying compounds, predicting properties, and modeling structure-activity relationships with remarkable accuracy which dominates human capabilities and drives the growth of the market. Automating all the chemical processes is achievable with the advancements in machine learning and artificial intelligence. Automation reduces the requirement for human intervention in routine tasks which allows experts to concentrate on more complex challenges.

Product Optimization.

Neural networks, an artificial intelligence method, learn patterns in vast production datasets from variables like temperatures, pressures, and material properties which determine optimal operating conditions across various unit operations. Additionally, AI continuously monitors output quality, adjusts parameters as needed, and predicts maintenance issues, reducing unplanned downtime.

Restraints

High investment requirements:

Purchasing advanced equipment and software, setting up AI infrastructure, conducting research and development, and integrating AI into existing processes require significant initial costs that obstruct the market's growth.

Lack of skilled workforce:

The insufficient number of experts proficient in AI technologies and the chemical domain presents many challenges as chemical firms cannot hire talent capable of creating and deploying AI solutions customized to their requirements. Many small and medium-sized chemical companies cannot afford these investments which obstruct the market's growth.

Opportunities

Predictive Analysis:

Predictive maintenance using artificial intelligence is important for optimizing plant performance, safety, and sustainability in the chemical industry. Advanced sensors, IoT devices, and machine learning algorithms, AI-based predictive maintenance solutions are monitoring equipment operations in real-time. These solutions are important in analyzing various operational parameters, detecting anomalies, and forecasting equipment failures with high accuracy before any visible signs appear.

Trend

Adoption of new AI techniques:

Artificial intelligence technologies such as machine learning and deep learning analyze extensive datasets containing chemical properties, structures, and reactions which enables the discovery of intricate patterns that aid in research and product development. Machine learning transforms drug discovery by predicting safe and effective molecular structures which significantly accelerates the process. Many chemical companies are investing heavily in AI startups that focus on developing technologies for the chemical industry.

Research Scope and Analysis

By Type

Software segment is expected to be the dominant force for AI in chemical market with the largest revenue share by the end of 2024, due to the ongoing software transformation aimed at the requirements of chemical industry. The growth of this segment is driven by increasing demand for efficient data storage, management, analysis, and sharing, particularly in drug research and development, which significantly boosts the adoption of software solutions among chemical industries.

Software tools with advanced AI algorithms are helpful in more accurate predictions, optimizations, and insights into chemical processes and materials.

These factors lead to increased efficiency, reduced costs, and accelerated innovation across various segments of the chemical industry like pharmaceuticals, and materials science. Integration of AI-powered software solutions with other advanced technologies such as IoT, big data analytics, and cloud computing is further driving the demand for software in the chemical market.

Hardware is showing notable growth due to rising demand for hardware components like AI memory and processors and increasing use of artificial intelligence algorithms for complex operations. AI processors widely known as neuromorphic processing units provide better speed and efficiency compared to traditional processors. It includes essential components such as reactors, separators, and advanced detection systems within intelligent laboratories that offer real-time monitoring and data integration.

By Technology

Machine learning is likely to dominate AI in the chemical market with the largest revenue share by the end of 2024, due to its learning ability and effectiveness in analyzing large datasets, spotting patterns, and making accurate predictions. It plays an important role in optimizing chemical processes, aiding in material discovery, and enhancing quality control in manufacturing. It is broadly used across many chemical processes from research and development to production and quality assurance which emphasizes its role in driving innovation and operational efficiencies. Integration of machine learning with quantum computing and reinforcement learning is allowing the discovery of new materials with specific properties and optimizing chemical reactions.

Deep learning is expected to experience notable growth throughout the forecasted period, due to the integration of sensor data, and machine learning models that detect faults, predict equipment failures and optimize production parameters in real-time. These techniques are useful in reducing downtime, & maintenance costs and enhancing overall efficiency and product quality.

Natural Language Processing is highly used within the chemical market, particularly in areas such as data analysis, knowledge extraction, and decision-making.

By Application

Discovery of new materials is anticipated to lead the AI in chemical market with the highest revenue share in 2024 due to the adoption of machine learning which analyses vast amounts of data to identify patterns and correlations that humans might miss. ML algorithms are capable of going through extensive databases of chemical properties, structures, and performance metrics to reveal novel combinations or compositions. These algorithms help optimize the parameters of material synthesis processes, such as temperature, pressure, and reactant concentrations, to achieve desired material characteristics, which drives the growth of this segment.

Computational chemistry and quantum computing are advanced machine learning technology that improves accuracy and scope of material discovery efforts. Production optimization as an application is showing notable growth as AI algorithms are capable of detecting equipment failures and maintenance requirements in chemical production facilities, thereby decreasing downtime and enhancing production schedules.

AI-driven analytics are used to identify opportunities for energy savings by optimizing resource usage and smoothening the production workflows. It is also helpful in maintaining product quality by analyzing production data to detect deviations from quality standards and allowing proactive measures to maintain product quality. Integration of AI with supply chain systems to optimize inventory levels, minimize stockouts, and streamline logistics, ensuring smooth production operations.

By End User

Base Chemicals & Petrochemicals are anticipated to dominate the AI in chemical market with the largest revenue share in 2024. Complex operations in base chemicals require advanced technologies like AI to optimize processes, improve yields, & reduce costs. The increasing need for sustainable practices & regulatory compliance is driving the adoption of AI solutions for efficient resource utilization & waste reduction. There are huge opportunities for AI applications such as predictive maintenance, anomaly detection, & real-time optimization due to the availability of vast amounts of data from sensors, equipment, and production processes in the petrochemical industry.

Specialty chemicals are anticipated to experience notable growth due to increasing demand for customized and high-performance chemicals across industries such as pharmaceuticals, electronics, and automotive. Advanced data analytics and modeling are used in predicting and optimizing properties & compositions due to the complexity and diversity of specialty chemical formulations. Companies are focusing on sustainability and green chemistry practices in specialty chemicals that use AI for eco-friendly product development, waste reduction, & energy efficiency.

AI in Chemical Market Report is segmented based on the following

By Type

- Software

- Hardware

- Services

By Technology

- Machine Learning

- Deep Learning

- Generative Models (GAN & VAE)

- Computer Vision

- Natural Language Processing (NLP)

- Others

By Application

- Discovery of new materials

- Production optimization

- Pricing optimization

- Load forecasting of raw materials

- Supply chain optimization

- Customer Insights

- Document Processing

- Feedstock optimization

- Process management & control

- Others

By End User

- Base Chemicals & Petrochemicals

- Specialty Chemicals

- Agrochemicals

- Commodity Chemicals

- Others

Regional Analysis

North America is expected to dominate the AI in chemical market with the largest revenue

share of 43.3% by the end of 2024. This region is leading due to technological infrastructure, cutting-edge research institutions, the presence of leading chemical firms, and supportive regulatory frameworks. They are well known for their adoption of AI technologies to improve efficiency across their research, development, and manufacturing operations. Leading companies in this region are making huge investments in crafting innovative AI tools and platforms.

Growing awareness of digitalization strategies and augmented research and development investments by chemical companies to increase the overall production processes. Increasing pharmaceutical and chemical manufacturing sectors in this region contribute to the growth of the chemical market. There is a higher concentration of IT companies and startups in this region that are actively engaged in ongoing AI research and development, driving the growth of this market. After North America, the Asia Pacific region is experiencing rapid growth due to the adoption of advanced technologies across various industries, supported by government funding and incentives aimed at promoting innovation.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

Key market players of AI in chemical markets include firms leading in the integration of AI tech into chemical research, development, and production. The major players operating in the AI in chemical market are Manuchar N.V., IMCD N.V., Univar Solutions Inc., Brenntag S.E., Sojitz Corporation, and ICC Industries Inc. These players are using AI to boost operational efficiencies, which is also helpful in the development of new chemical compounds, materials, and innovative processes that could significantly impact various industries, including pharmaceuticals, materials science, and specialty chemicals. Collaborations between chemical companies and AI technology providers are fostering innovation and accelerating the adoption of AI in specialty chemicals, positioning this sector as a key driver of AI growth in the chemical industry.

Some of the prominent players in the global artificial intelligence in chemical market are:

- Manuchar N.V

- IMCD N.V.

- Univar Solutions Inc.

- Brenntag S.E.

- Sojitz Corporation

- ICC Industries Inc.

- Azelis Group NV

- Tricon Energy Inc.

- Biesterfeld AG

- Omya AG

- Others

Recent Development

- In May 2023, TechBio startup Recursion announced its acquisition plans for AI-driven drug discovery companies Valence and Cyclica, intending to leverage biology to streamline and expedite drug development processes.

- In April 2023, Mitsui Chemicals and IBM Japan partnered to utilize IBM Watson Discovery and Generative Pre-trained Transformer (GPT) AI for accelerating the discovery of new product applications, aiming to increase Mitsui Chemicals' market share and sales through improved accuracy and speed.

- In January 2023, Bayer and Google Cloud disclosed a collaboration to enhance Bayer's quantum chemistry analysis for drug discovery using machine learning techniques.

- In March 2022, Yokogawa Electric Corporation and JSR Corporation announced the successful completion of a groundbreaking field trial where AI was utilized to autonomously operate a chemical plant for 35 days, marking a global first.

Report Details

| Report Characteristics |

| Market Size (2024) |

USD 2.0 Bn |

| Forecast Value (2033) |

USD 26.2 Bn |

| CAGR (2023-2032) |

33.0% |

| Historical Data |

2018 – 2023 |

| Forecast Data |

2024 – 2033 |

| Base Year |

2023 |

| Estimate Year |

2024 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Type (Software, Hardware, and Services), By Technology (Machine Learning, Deep Learning, Generative Models, Computer Vision, Natural Language Processing (NLP), and Others), By Application (Discovery of new materials, Production optimization, Pricing optimization, Load forecasting of raw materials, Supply chain optimization, Customer Insights, Document Processing, Feedstock optimization, Process management & control, and Others), By End User (Base Chemicals & Petrochemicals, Specialty Chemicals, Agrochemicals, Commodity Chemicals, and Others) |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia- Pacific– China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA

|

| Prominent Players |

Manuchar N.V, IMCD N.V., Univar Solutions Inc., Brenntag S.E., Sojitz Corporation, ICC Industries Inc., Azelis Group NV, Tricon Energy Inc., Biesterfeld AG, Omya AG, HELM AG, Sinochem Corporation, Petrochem Middle East FZE, and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |

Frequently Asked Questions

The Global AI in Chemical Market size is estimated to have a value of USD 1.1 billion in 2024 and is expected to reach USD 14.9 billion by the end of 2033.

North America is expected to be the largest market share for the Global AI in Chemical Market with a share of about 43.3 % in 2024.

Some of the major key players in the Global AI in Chemical Market are Manuchar N.V., IMCD N.V., Univar Solutions Inc., Brenntag S.E., Sojitz Corporation, ICC Industries Inc., and many others.

The market is growing at a CAGR of 33.0 percent over the forecasted period.