Egg Handling and Packaging Machines Market encompasses sophisticated equipment developed specifically to streamline egg collection, sorting, cleaning, packaging, and storage in commercial production settings. This market encompasses various automated systems designed to improve operational efficiencies, reduce manual labor, and meet high hygiene standards. Technology advances have given these machines improved accuracy, speed, and traceability to meet the increasing demand for high-quality eggs processed safely. Key drivers in this market include increasing egg consumption, automation advances, and food safety concerns; executives must understand this market to optimize production processes and sustain a competitive edge.

The Egg Handling and Packaging Machines Market is poised for robust expansion, propelled by rising global egg consumption as well as operational efficiency imperatives. Technology innovations such as AI-enhanced sorting systems, sophisticated cleaning technologies, and high-speed packaging lines are redefining this sector and meeting critical industry requirements for precision, speed, and food safety compliance. Furthermore, technological upgrades not only streamline operations but also reduce labor costs and increase throughput - aligning with larger trends toward operational excellence and efficiency.

Regionally, North America and Europe exhibit particularly strong performance for egg production facilities rapidly adopting advanced machinery. Meanwhile, Asia-Pacific is quickly emerging as an area of high growth driven by urbanization and an increase in egg demand, prompting more efficient handling and packaging solutions that meet rising consumer expectations. Furthermore, an emphasis is being placed on sustainability with eco-friendly packaging options becoming more prominent across industries to adapt with environmental regulations as well as consumer expectations.

Staying current with trends is important for executives and strategic leaders; investing in state-of-the-art handling and packaging technology will not only increase operational efficiencies but also strengthen competitive positions. By keeping abreast of technological innovations and regional market developments, companies can use insights gained to navigate through the evolving Egg Handling and Packaging Machines Market with confidence and seize emerging opportunities.

Key Takeaways

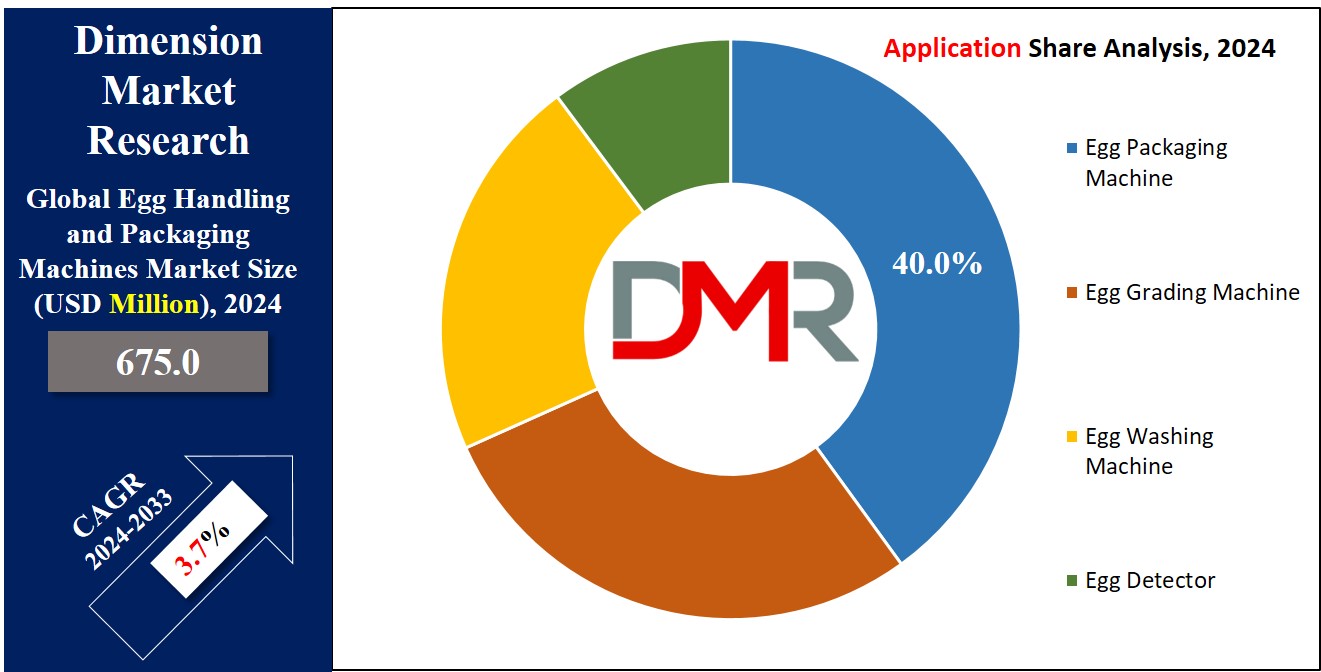

- Market Growth: Egg Handling and Packaging Machines Market - 2024 - USD 675.0 million, 2033 - USD 939.4 million (3.7% CAGR).

- Dominating Segment: Egg Packaging Machines, fostering around a share of 40% on the back of increasing demand for proper distribution channels and freshness maintenance.

- Technological Advancements: AI-based sorting systems and smart is the latest trend in this sector which has enhanced the level of accuracy speed along with tracking ability.

- Regional Leadership: The main markets are North America and Europe, which derive from established food processing infrastructures and technological adoptions at a high level. With urbanization and increased egg demand, Asia-Pacific is increasing as a growth engine.

- Key Drivers: This expansion is driven by an increase in egg consumption, automation developments, and growing food safety concerns.

Use Cases

- High-Efficiency Production Facilities: Automated systems in large egg production facilities boost throughput and maintain hygiene by integrating AI-driven sorting and high-speed packaging technologies, addressing the growing global demand.

- Egg Processing Plants: Sophisticated grading, washing, and packaging machinery in egg processing plants ensures high quality and safety of liquid, powdered, or frozen egg products, meeting stringent food safety standards.

- Urbanizing Asia-Pacific Markets: Modern handling and packaging solutions cater to increasing consumer demand for processed eggs in urbanizing regions like Asia-Pacific, optimizing production efficiency and quality.

- Sustainability-Driven Producers: Eco-friendly packaging and energy-efficient machinery appeal to environmentally conscious consumers, helping producers comply with regulations and enhance their market position.

- E-Commerce Adaptation: Durable and tamper-evident packaging solutions are essential for e-commerce, ensuring safe transit and freshness of eggs while meeting online shopping demands.

Driving Factors

Improve Production Efficiency Now

Improving production efficiency is central to the Egg Handling and Packaging Machines Market's expansion. As egg producers struggle to meet global consumption - projected at 82 million metric tons by 2025 - efficiency becomes of critical importance in production processes. Automation technologies such as artificial intelligence-powered sorting systems and high-speed packaging lines significantly increase operational throughput while decreasing manual labor requirements. These innovations not only streamline the handling process but also decrease cycle times for each cycle, thus increasing overall productivity. Automatic egg handling systems have proven their value by outpacing manual methods by as much as 50%, leading to greater efficiency and reduced costs. Companies are investing heavily in modern egg-handling machinery to optimize production processes while meeting growing demands with minimal operational interruptions.

Focus on Safety, Hygiene, and Cleanliness

Safety, hygiene, and cleanliness have become cornerstones of the egg handling and packaging machines market with their rise to standards and advancements in technological development. Egg producers must comply with stringent food safety regulations and an increasing consumer interest in hygiene; hence they are increasingly investing in machinery that ensures superior sanitation and contamination prevention.

Advanced cleaning technologies, including automated washing systems with precise controls, are indispensable in maintaining high hygiene standards. Furthermore, modern packaging solutions designed to protect against contamination have become mainstream solutions. These measures not only comply with regulatory requirements but also help build consumer trust and facilitate the adoption of advanced handling equipment. Hygienic design principles incorporated into machinery--such as easy-to-clean surfaces and antimicrobial coatings--have become key factors in meeting both governmental standards and consumer expectations.

Rapidly Expanding Demand for Convenient, Ready-to-Eat Food Products

Rising consumer demands for products that require minimal preparation are driving growth in the Egg Handling and Packaging Machines Market. Consumer lifestyles have become more hectic over time and people increasingly prefer products that do not require much prep work before eating them. This trend can be seen through an increase in consumption of pre-packaged and ready-to-eat egg products such as boiled eggs and sandwich versions, which egg producers are responding to with packaging solutions that preserve freshness while providing convenience. Automated packaging machines equipped with features like portion control and tamper-evident seals are essential in meeting consumer preferences.

Growth Opportunities

Adopting Smart Packaging Technologies

Integration of smart packaging solutions offers a significant opportunity for market expansion. Technology such as IoT-enabled sensors and RFID tags is revolutionizing how eggs are tracked through their supply chains, offering real-time monitoring of storage conditions and product freshness, improving traceability, reducing waste, and offering increased transparency to consumers who demand transparency and quality assurance from products they consume. Smart packaging offers an innovative competitive advantage by guaranteeing optimal safety and integrity - thus aligning with broader trends of digital transformation in the food industry - driving considerable investment in advanced packaging solutions.

Custom Egg Customization Services

Organic, free-range, and fortified eggs have seen tremendous growth over the last several years, creating an increasing need for tailored handling and packaging solutions to meet consumer demand for premium eggs that satisfy specific dietary or ethical preferences. Manufacturers can take advantage of this demand to develop customized machinery that accommodates various egg types as well as packaging requirements - this may involve adjustable settings to cater to various egg sizes or formats designed to highlight product attributes - catering to niche markets allows businesses to differentiate their offerings while tapping into premium egg market niches.

Focus on Sustainable Practices

Sustainability has quickly become a priority in the egg industry, fueling increased interest in eco-friendly packaging solutions. As environmental regulations tighten and consumers become more eco-aware, there is increasing focus on reducing packaging materials' ecological footprint and developing biodegradable or recyclable options as well as energy-saving manufacturing processes to meet regulatory expectations and appeal to eco-conscious customers. Adopting sustainable practices not only meets regulatory expectations but also strengthens brand image while appealing to environmentalists.

Key Trends

Advanced Grading and Sorting Technologies

Grading and sorting technologies have had an exponentially growing influence on egg-handling industries. Today's modern systems employing AI and machine vision technology are revolutionizing egg sorting accuracy and efficiency by sorting eggs according to size, quality, and shell condition - increasing throughput while meeting stringent quality standards - these cutting-edge systems also identify imperfections manual processes miss thus reducing waste while improving overall product quality - not to mention helping ensure compliance with increasingly stringent food safety regulations.

Increased Demand for E-commerce Solutions

E-commerce Solutions the rapid expansion of e-commerce is dramatically changing egg handling and packaging markets. As consumers shift toward online grocery shopping, demand for safe and efficient packaging solutions to ensure safe deliveries increases significantly. E-commerce logistics require durable packaging that protects during transit while maintaining freshness - companies are investing in innovations specifically tailored to this channel, such as tamper-evident features or increased cushioning materials that meet both consumer expectations as well as logistical needs. This trend highlights the necessity for adaptable solutions that meet both consumer expectations as well as logistical requirements.

Technological Advancements in Packaging

Technological innovations in packaging are creating significant disruption in the market. Technologies like smart packaging with features like QR codes and embedded sensors are increasing traceability and consumer engagement while meeting consumer demands for transparency and convenience. Meanwhile, advancements in sustainable materials like biodegradable and recyclable plastics address environmental concerns while meeting regulatory pressures; becoming a key differentiator between companies.

Restraining Factors

Maintenance and Operational Expenses

Maintenance and operational expenses represent one of the main constraints facing the Egg Handling and Packaging Machines Market. As production technologies advance, costs associated with maintaining and operating more complex machinery have skyrocketed. High-tech equipment often requires expensive and time-consuming maintenance services, and industry reports indicate that up to 20% of operational expenses may go toward upkeep costs for egg handling systems. Financial burdens may act as a deterrent for smaller producers with tight budgets, slowing the adoption of innovative technologies. Furthermore, operational expenses related to energy consumption and spare parts usage add additional expenses related to running advanced systems - forcing companies to delay investing in new machinery, potentially slowing market expansion by slowing its adoption of revolutionary innovations.

Alternative protein sources present fierce competition

Competition from alternative protein sources is another significant impediment to the growth of the Egg Handling and Packaging Machines Market. Consumer preferences have begun shifting towards plant-based proteins produced in laboratories over animal products as consumer preferences shift away from them. The global plant-based protein market, estimated to be worth approximately $10 billion by 2023, is expanding quickly and posing a direct challenge to the egg industry. As alternative proteins gain ground, egg demand may decline significantly, impacting investment potential in egg handling and packaging technologies. Producers may experience reduced margins as they compete against one another - thus decreasing their willingness to invest in advanced machinery or innovations.

Technological Obsolescence

Technological obsolescence poses a key threat to the Egg Handling and Packaging Machines Market. Rapid advances in technology mean machinery quickly becomes outdated, necessitating frequent upgrades or replacements. Technological disruption combined with rising costs of new equipment can strain financial resources and cause instability for manufacturers. High-tech egg-handling systems typically last 5 to 7 years before they require significant upgrades to remain competitive in their field. Due to this dynamic, businesses may hesitate to adopt new technologies out of fears over obsolescence and subsequent investment costs, leading them to hold off from adopting cutting-edge innovations that may become outdated over time. Market growth may therefore be restricted as businesses struggle with the delicate balance between innovation needs and investments in potentially outdated technology.

Research Scope Analysis

By Type

In 2023, Egg Packaging Machines held the leading market position within the Product Type segment of the Egg Handling and Packaging Machines Market with approximately 40% market share. This significant share underscores their crucial role in ensuring safe and efficient egg distribution. Consumer demand for convenience foods has led to a greater need for advanced packaging solutions that preserve freshness during transportation and retail sales.

Egg Grading Machines represented approximately 30% of the market, thanks to their essential role of sorting eggs by quality, size, and shell condition. As demand for high-quality eggs continues to soar, sophisticated grading technologies have become essential for producers in meeting both regulatory standards and consumer expectations. Grading machines equipped with AI/machine vision technologies enhance sorting accuracy and operational efficiency while reinforcing their significant market presence.

Egg Washing Machines represented roughly 20% of global sales. These machines play an essential role in maintaining hygiene and food safety standards by thoroughly washing eggs before packaging, thus contributing to rising food safety awareness and strict regulations surrounding egg production - creating steady demand for washing machines that ensure thorough cleaning and prevent contamination.

Egg Detectors represented approximately 10% of the market. Though relatively smaller in scale, egg detectors play an essential role in identifying defects and maintaining quality control; their capacity for reducing waste while improving product quality helps ensure their continued existence in the marketplace.

By Application

Chicken Farms were the clear market leaders in 2023 in the Product Type segment of the Egg Handling and Packaging Machines Market, accounting for 55% of the total market share. This success can be attributed to their expansive scale of operations and large volume of egg production at commercial chicken farms; as these operations utilize sophisticated handling and packaging technologies to efficiently manage large volumes of eggs without impacting product quality or operational efficiency; their heavy reliance on automation machinery highlights their significant influence in this space.

Egg Processing Factory facilities accounted for roughly 30% of the market share. Egg processing factories play a vital role in turning raw eggs into liquid, powdered, or frozen varieties - convenient and versatile components of food manufacturing - that require sophisticated processing equipment for manufacturing purposes. Demand has driven investment in such facilities while special handling and packaging solutions must also be offered to accommodate various product types while upholding high standards of hygiene and quality standards.

15% of the egg handling and packaging market can be divided up among smaller segments such as niche applications and specialty producers, which contribute significantly by fulfilling specific needs or trends within this industry.

The Egg Handling and Packaging Machines Market Report is segmented based on the following:

By Type

- Egg Packaging Machine

- Egg Grading Machine

- Egg Washing Machine

- Egg Detector

By Application

- Chicken Farm

- Egg Processing Factory

Regional Analysis

North America holds an impressive 32% of the global Egg Handling and Packaging Machines Market as of 2023, thanks to its well-developed infrastructure, high levels of technological innovation, robust food processing sector, advanced automation systems and rigorous food safety standards which set benchmarks in their industry and contribute significantly to market expansions.

Europe currently accounts for approximately 27% of global food markets, thanks to its emphasis on high quality standards, technological innovations, and sustainable practices. Germany and the Netherlands in particular play an integral role in supporting this share through their advanced food processing technologies and commitment to eco-friendly solutions.

Asia Pacific has quickly emerged as a key growth driver, commanding 23% market share. This expansion can be attributed to rapid urbanization, rising disposable incomes, and consumer appetite for processed and packaged food products; China and India being among the driving forces of this change and increasing Asia Pacific's overall market presence.

By Region

North America

Europe

- Germany

- U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Competitive Landscape

2023 is witnessing several key players making substantial impacts in the global Egg Handling and Packaging Machines Market, each contributing unique strengths that drive industry innovation and growth. MOBA stands out among these market players due to its advanced egg-handling solutions such as AI-driven sorting systems and high-precision grading machines; MOBA also leverages digital solutions to enhance operational efficiency and accuracy, which makes them popular with large-scale egg producers. Furthermore, its integration of digital solutions satisfies industry requirements for increased productivity and product quality, further strengthening its influential position within this competitive industry segment.

Sanovo Group and NABEL are essential players, providing comprehensive egg handling and processing solutions. Sanovo stands out by producing energy-efficient and sustainable machinery, catering to an ever-increasing need for environmentally conscious operations. Their innovations in egg grading, washing and processing showcase this commitment. Similarly, NABEL stands out with customizable flexible solutions tailored specifically to different market segments; from large commercial farms to specialty producers. Their ability to tailor equipment according to specific requirements supports market versatility and adaption.

Prinzen, Kyowa Machinery, Seyang, and Plasson Do Brasil also play a significant role in shaping this market with their advanced technologies. Prinzen and Kyowa Machinery have become widely renowned for their advancements in high-speed packaging and grading systems, reflecting industry trends toward increased automation. Seyang, Plasson Do Brasil, and ZENYER provide reliable machinery designed to meet regional as well as global needs. Mintai, Sime-Tek, VOLKER GmbH, and EggTec all specialize in innovative food safety technologies that ensure regulatory compliance while upholding product integrity. Yamasa adds advanced features to traditional machinery that meet evolving industry needs; collectively these players drive market expansion with technological breakthroughs and responses tailored specifically to market demands.

Some of the prominent players in the Global Egg Handling and Packaging Machines Market are:

- MOBA

- Sanovo Group

- NABEL

- Prinzen

- Kyowa Machinery

- Seyang

- Plasson Do Brasil

- ZENYER

- Mintai

- Sime-Tek

- VÖLKER GmbH

- EggTec

- Yamasa

Recent developments

- In August 2024: Some manufacturers introduced multi-stage filtration systems that further help in the separation of water and particulates from diesel fuel which is to make sure that this ushers engine efficiency.

- In May 2024: In high-end models, IoT-enabled sensors and real-time data analytics have become common whereby they provide continuous monitoring with predictive maintenance alerts.

- In December 2023: Eco-friendly materials are taking over the use of biodegradable and recyclable components in building separators as a typical example.

- In September 2023: The latest corrosion-resistant coatings are playing a role in increasing the lifespan of the separator more so in harsh marine and industrial environments.

- In November 2022: Small-footprint modular designs are introduced and can serve highly space-restricted applications with very high separation efficiency.

Report Details

| Report Characteristics |

| Market Size (2023) |

USD 675.0 Million |

| Forecast Value (2032) |

USD 939.4 Million |

| CAGR (2023-2032) |

3.7% |

| Historical Data |

2018 – 2023 |

| Forecast Data |

2024 – 2033 |

| Base Year |

2023 |

| Estimate Year |

2024 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors and etc. |

| Segments Covered |

By Type(Egg Packaging Machine, Egg Grading Machine, Egg Washing Machine, Egg Detector), By Application(Chicken Farm, Egg Processing Factory) |

| Regional Coverage |

North America – The US and Canada; Europe – Germany, The UK, France, Russia, Spain, Italy, Benelux, Nordic, & Rest of Europe; Asia- Pacific– China, Japan, South Korea, India, ANZ, ASEAN, Rest of APAC; Latin America – Brazil, Mexico, Argentina, Colombia, Rest of Latin America; Middle East & Africa – Saudi Arabia, UAE, South Africa, Turkey, Egypt, Israel, & Rest of MEA

|

| Prominent Players |

MOBA, Sanovo Group, NABEL, Prinzen, Kyowa Machinery, Seyang, Plasson Do Brasil, ZENYER, Mintai, Sime-Tek, VÖLKER GmbH, EggTec, Yamasa |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days and 5 analysts working days respectively. |