The global flotation reagents market is one of the key sectors within the mining and mineral treatment industries, comprising chemicals known as flotation reagents used for to separate valuable minerals from waste materials or impurities.

The flotation reagent market is expected to see a gradual rise as industries look toward efficiency and sustainability. This process enjoys extensive application in mining, wastewater treatment, and several other industries when the effective separation of materials is highly relevant in terms of efficiency and cost.

Some industries, such as energy industries, construction industries, and manufacturing industries, take revenge on minerals, specifically copper, gold, and coal. This has acted as a boom to further build up the flotation reagent industry.

Key players in the global flotation reagent market have invested significantly in research and development of more eco-friendly reagent products; such as renewable materials that use minimal amounts of resources like fossil fuels. With increased environmental regulations and efforts toward more environmentally responsible mining practices; companies strive to reduce their environmental footprint when processing minerals.

Due to an increase in mineral extraction processes across industries such as mining, metals, and chemicals, flotation reagents have experienced an upswing in demand. An emphasis on resource optimization and efficient processing techniques has driven an adoption of specific reagents to maximize recovery rates in froth flotation processes.

Recent innovations in sustainable and eco-friendly flotation reagents are leading the market to change. Companies have introduced biodegradable and non-toxic solutions in response to rising environmental demand for eco-friendly alternatives in mining activities while simultaneously improving performance efficiency. These developments aim to reduce the environmental impact of mining operations without diminishing performance efficiency.

Mining remains the top end-user, with flotation reagents playing an essential role in ore separation and processing. Exploration activities - particularly in emerging markets - should drive demand for high performance reagents. Furthermore, more mining companies are adopting automation/digital technologies which may further increase efficiency with regards to using flotation reagents efficiently.

Opportunities in the flotation reagents market have expanded rapidly in Asia-Pacific and Africa due to industrialization's rise. Mining activities and mineral exploration activities in these regions have spurred manufacturers to focus their product development strategies around regional mining companies; and collaborate on product distribution with them as an effective strategy for increasing market penetration and meeting regional demands.

As per the Eprints@NML, the flotation reagents market is pivotal in enhancing the beneficiation of fine coal, a critical process for particles finer than 0.5 mm. Froth flotation, established since the 1920s, processes approximately 142 million tonnes of fine coal globally each year. With mechanized mining generating significant fines (-500 microns) comprising 20–30% of total plant feed, optimizing recovery has become imperative.

Given the low market value of clean coal, cost-effective solutions are crucial to maximize yields. The demand for advanced flotation reagents aligns with these needs, driving innovation and efficiency across the coal processing sector worldwide.

The US Flotation Reagents Market

The US Flotation Reagents Market is projected to be valued at USD 2.5 billion in 2024. It is expected to witness subsequent growth in the upcoming period, holding USD 4.2 billion in 2033 at a CAGR of 5.8%.

The market for flotation reagents in the United States has grown into an influential factor in the global industry, owing to the mature mining sector in the country and increasing demand for effective mineral processing technologies. The developed infrastructure, rich industrial base, and innovative attitude of the country further benefit the United States market. Flotation reagents traditionally find their application in mining sectors, whereas wastewater treatments and environmental management stand out as fast-emerging applications.

United States-based top players such as Ecolab Inc. and Cytec Solvay Group, have made strides toward pushing innovation in the flotation reagent marketplace. These four companies are widely known for collaborating on advanced reagent formulations to meet environmental regulations and increase mineral separation efficiency.

Nevada, Arizona, and Colorado's mining industries rely heavily on flotation reagents for extracting major minerals such as copper, gold, and coal from ore. Furthermore, government regulations designed to encourage environmentally responsible mining methods and improve water management have resulted in greater demand for flotation reagents.

However, these markets face fluctuating production costs and requirements to adhere to stringent environmental standards. With newer technologies and higher mineral extraction levels on the rise, demand will likely drive upward momentum within the US flotation reagent market.

Flotation Reagents Market Key Takeaways

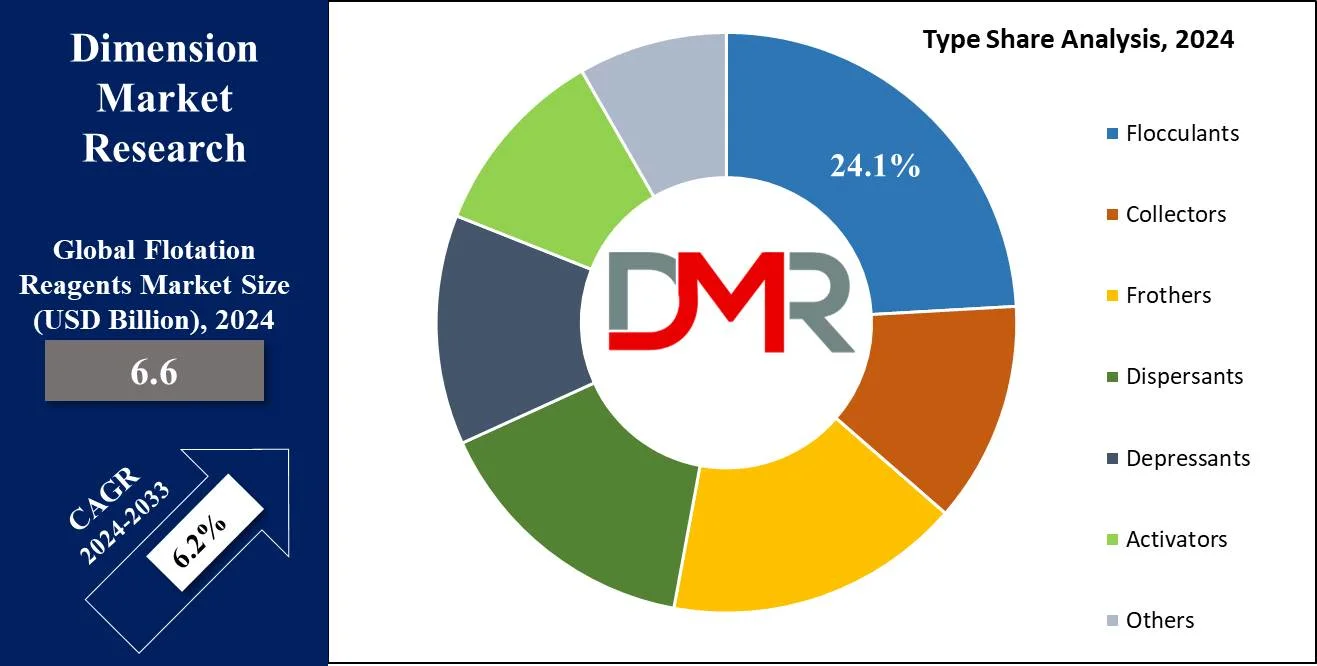

- Global Market Value: The global flotation reagents market size is estimated to have a value of USD 6.6 billion in 2024, which is further anticipated to reach USD 11.4 billion by the end of 2033.

- Global Market Value: The market is growing at a CAGR of 6.2 percent over the forecasted period.

- The US Market Value: The US flotation reagents market is projected to be valued at USD 4.2 billion in 2033 from the base value of USD 2.5 billion in 2024 at a CAGR of 5.8%.

- By Type Segment Analysis: Flocculants are projected to dominate the type segment of the global flotation reagents market as they hold 24.1% of the market share in 2024.

- By Application Segment Analysis: Explosives & drilling is anticipated to dominate the application segment in this market as it will hold 32.2% of the market share by the end of 2024.

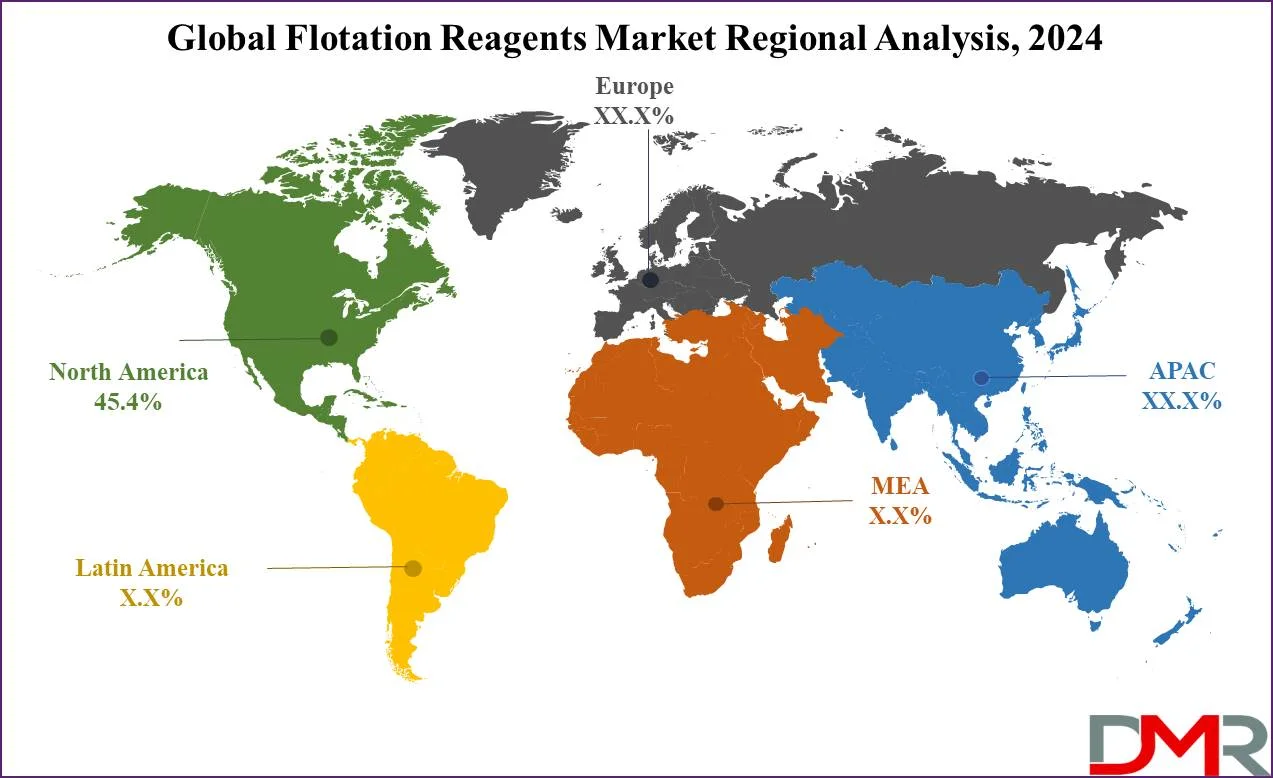

- Regional Analysis: North America is expected to have the largest market share in the global flotation reagents market with a share of about 45.4% in 2024.

Flotation Reagents Market Use Cases

- Gold Mining: Flotation reagents play a very vital role in gold mining, especially through the selectivity of the flotation processes for improving gold recovery while reducing operational costs.

- Wastewater Treatment: flotation reagents in wastewater treatment, including removal of contaminants, suspended solids, and organic materials, can be considered to optimize water quality and make the treatment process more effective and non-polluting.

- Coal Mining: Flotation reagents play an important role in coal mining activities for their function: to separate valuable coal from impurities and increase the coal recovery rate with minimized energy consumption while improving the overall process efficiency.

- Pharmaceutical Industry: Some reagents applied in the flotation process find use in purification within the pharmaceutical industry. Therefore, these reagents actively separate APIs from other impurities, hence giving way to APIs of high purity and quality.

Flotation Reagents Market Dynamic

Trends

Eco-Friendly Reagent DevelopmentOne of the major trends being witnessed in the flotation reagents market is the increasing focus on greener formulations of reagents. The mining industry, among others, and also wastewater treatment, is under growing pressure to lessen its impact on the environment.

For this reason, there has been a major transition toward biodegradable and non-toxic reagents with performance comparable or superior to that of traditional reagents. This is a trend fostered increasingly by governments across the world, particularly in regions such as North America and Europe, by the implementation of strict environmental regulations to even greener solutions.

Automation and Digitalization in Mineral Processing

The other trend in the limelight has been integrating automation and

digital technologies into the flotation process. Advanced data analytics,

AI, and

ML technologies make optimizations of reagents used, thus enhancing mineral recoveries and reducing incidences of waste.

Essentially, mining companies continue to adopt such technologies in the move for competitive advantage, improving operational efficiency while ensuring more precise usage of reagents. Fully automated systems that control and optimize all aspects of reagent performance in real-time represent a growing trend, the cost benefits derived from these systems, coupled with process outcomes, are very significant.

Growth Drivers

Rising Demand for Minerals in Emerging Markets

The features of industrialization and urbanization through emerging markets within the Asia-Pacific and Latin America drive up demand for minerals and metals. In return, this overall increase in mining activities has a positive effect on the demand for flotation reagents, necessary for the effective separation of valuable ores to help these regions meet growing resource demands. Mining of essential materials in developing countries, which includes but is not limited to China, India, and Brazil, has increased demand for high-performance flotation reagents that optimize mineral recovery.

Stringent Environmental and Water Management Regulations

Global regulations involving environmental protection and the management of water have, therefore, played an influential role in the growth of the flotation reagents market. With growing pressures on the mining and industrial sectors to be more environmentally friendly, demand for reagents providing better separation efficiency with reduced environmental degradation has increased significantly. Water conservation and wastewater treatment are also crucial in various industries, and flotation reagents play an important role in treating and re-utilizing industrial effluents, adding to the growth of this market segment.

Growth Opportunities

Innovative Formulations for Selective Reagent Use

The development of selective reagent formulations This, in turn, opens up huge avenues of growth for players operating in this market: the development of selective reagent formulations. The reagents are supposed to attach themselves to specific minerals or impurities and allow greater efficiency and selectivity of mineral separation.

Such innovations will thus not only increase the recovery rate but also reduce the consumption of the reagent, making the overall process more economical and environment-friendly. Ongoing company investments in R&D are likely to lead to more selective and efficient formulations, thus driving the demand for flotation reagents across industries.

Expansion in Wastewater Treatment and Environmental Applications

the rising demand for effective systems in wastewater treatment applications is taken to be one of the key opportunities for flotation reagent manufacturers. This is because, with industries increasingly coming under pressure to manage water resources responsibly, there has been immense demand in recent times for water treatment applications owing to the important role flotation plays in removing contaminants from water.

The demand is particularly very high in industries such as textiles, pharmaceuticals, and food processing given the treatment of wastewater that also forms part of compliance measures in operations. The demand for the flotation reagent will continue to grow with new development and wider use of advanced wastewater treatment technologies in more industries.

Restraints

High Production Costs of Advanced Reagents

One of the major challenges in the flotation reagents market is the high production cost of advanced reagents. In most cases, the development of advanced functionalities making the reagent environmentally friendly often involves expensive raw materials and complex manufacturing processes. These high costs stand out as obstacles to wide diffusion in regions and industries sensitive to the price of their raw materials. Moreover, the instability of raw material prices can turn the case for the worse, making it hard for companies to keep up with the same production cost and profitability.

Complex Regulatory and Compliance Requirements

Complex regulatory and compliance requirements for flotation reagent manufacturers also face significant challenges from stringent environmental regulations that have been enacted to control the use of chemicals in mining, wastewater treatment, and other industries.

In many instances, compliance is going to mean extensive investment in R&D as companies develop reagents that meet environmental standards and sacrifice performance. Companies failing to comply with such regulations are likely to attract penalties, restricted access to markets, and damage to their reputation. With ever-improving environmental standards, companies are constantly having to adapt; this increases the difficulty and expense of their production.

Research Scope and Analysis

By Type

Flocculants are projected to dominate the type segment of the global flotation reagents market as they hold 24.1% of the market share in 2024. Flocculants have dominated the flotation reagents market because of their vital role in improving the processes of solid-liquid separation in various industries, including mineral processes and wastewater. During mineral processing, a flocculant improves this efficiency in froth flotation through the aggregation of fine particles into larger clusters that facilitate easy separation of valuable minerals from unwanted materials.

These multi-values mineral separation process in mining, especially for the more valuable metals like gold, silver, and copper, is quite essential. Flocculants save time and reduce energy usage in separation processes. Flocculants also play an important role in the treatment of wastewater, which helps in the removal of suspended solids and other impurities from industrial wastes. Satisfaction of stringent environmental laws by industries is being helped through better quality water and this creates a way for the efficient reutilization of water. This has become a significant reason behind the demand for flocculants in the textile, chemical, and food industries.

The cost-effectiveness and versatility of flocculants make them the leading fingerprints in the flotation reagents market. Against the performance of other kinds of reagents, the action of flocculants is higher for a broad range of applications, making them indispensable both in industrial processes and for environmental purposes.

The growing emphasis on sustainability and the need for environmentally friendly chemicals has led to the development of biodegradable and non-toxic flocculants, further solidifying their market leadership. As industries are still considering ways for better and practical performance, flocculants might remain in the leading position in the flotation reagents market, particularly because of companies working on innovation and maintaining environmental standards.

By Application

Explosives & drilling is anticipated to dominate the application segment in the global flotation reagents market as it will hold 32.2% of the market share by the end of 2024. The segment of explosives and drilling dominates the flotation reagents market due to their important role in the successful and efficient extraction and processing of minerals in mining operations. Application areas for flotation reagents are very huge, ranging in quantity, especially for the separation of important ores from their impurities in explosives and drilling-related processes.

These reagents are applied to enhance this separation in the mineral extraction process, thus improving recovery rates of key metals such as gold, copper, and silver and reducing processed waste material. Efficiency and precision gained by flotation reagents during drilling and explosive operations are quite important in increasing resource utilization and reducing impacts on the environment. Precise mineral extraction is highly in demand, especially in large industries related to energy and electronics. This entails that the use of high-performance reagents among mining companies is indispensable.

In addition, flotation reagents are also used in the purification of raw materials that are subsequently applied in the production of explosives. Because the purification of raw materials is an issue of safety and quality, this further explains the need for flotation reagents within the explosives and drilling sector. The expansion of infrastructure projects across the world, combined with the growth in urbanization and industrial activities, has continuously increased the demand for minerals. These factors drive the need for more efficient and reliable techniques of extraction.

In this regard, the flotation reagents used in this industry enable mining companies to meet these increasing demands within acceptable environmental and safety legislation. New, innovative formulations of reagents for explosive and drilling applications will continue to be the key drivers in this dominant market segment.

The Flotation Reagents Market Report is segmented on the basis of the following

By Type

- Flocculants

- Organic Flocculants

- Inorganic Flocculants

- Natural Flocculants

- Synthetic Flocculants

- Collectors

- Anionic Collectors

- Cationic Collectors

- Non-ionic Collectors

- Amphoteric Collectors

- Frothers

- Alcohol-based Frothers

- Hydrocarbon-based Frothers

- Polyglycol Frothers

- Dispersants

- Sodium Silicate

- Polyacrylates

- Lignosulfonates

- Phosphate-based Dispersants

- Depressants

- Organic Depressants

- Inorganic Depressants

- Sodium Cyanide

- Zinc Sulfate

- Activators

- Copper Sulfate

- Sulfuric Acid

- Sodium Carbonate

- Others

By Application

- Explosives & Drilling

- Mineral Processing

- Water & Wastewater Treatment

- Paper & Pulp Processing

- Oil & Gas

- Others

Flotation Reagents Market Regional Analysis

North America is projected to dominate the global floatation reagents market as it

holds 45.4% of total market revenue by the end of 2024 which is further expected to show subsequent growth in the upcoming period of 2033.

Having a higher share of the flotation reagents market, North America could be attributed to its developed mining industry with a high technological profile and a full approach to environmental protection. The region is rich in mineral resources, especially in the USA and Canada, where vast copper deposits are unfolded along with substantial gold resources and coal.

All these abundant supplies of natural resources feed the demand for efficient technologies related to mineral processing, in which the flotation reagents play a gradually major role in maintaining the highest possible recovery rates and a minimum of lost mining materials.

In addition, North America has a highly developed infrastructure for research and development, especially in the industries of chemicals and mineral treatment. Large companies in the region lead in developing new, environmentally friendly flotation reagents to meet the very demanding legislation laid down by both the United States Environmental Protection Agency and the Canadian government. These regulatory environments have already inspired the formulation of biodegradable, non-toxic reagents that place North American companies at the forefront of sustainable mining.

Besides its technological prowess, North America has become a force to be reckoned with in the global market for flotation reagents on issues of sustainability and eco-friendly solutions. Companies within the region now focus increasingly on sustainable mineral processes through reagents that would not only improve recovery rates but reduce mining operations' impact on the environment. This places the region in the leading position concerning sustainable mineral processing technologies.

Furthermore, regional government policy in this region has also been another key factor for maintaining market position. For example, the United States government has adopted policies to reduce the dependence of the country on mineral imports, which in return increased mining activities within the country. Thus, demand for advanced flotation reagents grew manifold and favored North America as one of the major markets for advanced flotation reagents.

By Region

North America

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Flotation Reagents Market Competitive Landscape

Competition remains fierce in the market for flotation reagents among large players, each trying to improve their share through innovative approaches, strategic partnerships, and mergers and acquisitions. Global leading companies such as BASF SE, Solvay SA, and Clariant International Ltd. have carved out a high market share in the industry because of their diversified product portfolio, strong distribution network, and continuous investment in research and development.

These key players now focus on the development of more efficient and greener flotation reagents, since there is an increasing demand for sustainability in mining and wastewater treatment. Companies, for instance, are investing in the formulation of reagents that are biodegradable and non-toxic to meet the demand for strict environmental regulations and the fast-growing demand for eco-friendly products. Smaller, regional players also evidence growth in their more specialized reagent offerings for specific industrial applications. These companies very often aim at niche markets, providing new solutions to solve particular needs of a certain industry or region.

Mergers and acquisitions are one of the prevalent strategies adopted by major market participants to strengthen their market positions in the global market. For instance, BASF SE acquired Ciba Specialty Chemicals, thus enabling the former to strengthen its product portfolio of flotation reagents as well as extend its geographical presence in the global markets. Further consolidation is expected in the flotation reagents market, mostly about diversification of portfolio to capitalize on newer emerging opportunities.

Some of the prominent players in the Global Flotation Reagents Market are

- Huntsman

- BASF SE

- The DOW Chemical Company

- AkzoNobel

- Clariant AG

- Kemira OYJ

- Cytec Solvay Group

- Evonik Industries

- Orica Limited

- SNF Floerger SAS

- Ecolab

- IXOM

- Nalco Company

- Nasaco International Ltd

- Other Key Players

Recent Developments

- July 2024: Solvay SA announced the expansion of its sustainable flotation reagents portfolio with the launch of a new biodegradable reagent for copper ore flotation, aimed at reducing environmental impact and improving efficiency.

- April 2024: BASF SE introduced a new high-performance reagent for the flotation of industrial minerals, designed to enhance the recovery rate while reducing energy consumption in mineral processing operations.

- January 2024: Clariant International Ltd. launched an innovative froth flotation reagent optimized for the flotation of precious metals, including gold and silver, catering to increasing demand from mining companies focused on resource efficiency.

- November 2023: Kemira Oyj announced the development of a new generation of flotation reagents tailored for use in wastewater treatment, aimed at improving contaminant removal and supporting water recycling efforts in industrial applications.

- August 2023: Dow Chemical Company introduced a new reagent blend for use in coal flotation, which enhances the separation of impurities and reduces the use of water in the flotation process, offering a more sustainable solution for coal mining operations.

- May 2023: AkzoNobel unveiled a range of flotation reagents formulated specifically for phosphate rock flotation, designed to optimize phosphate recovery and cater to the growing demand in the agricultural sector.

- February 2023: ArrMaz announced a collaboration with a leading mining company to develop customized flotation reagents for lithium extraction, addressing the surge in demand for lithium-ion battery production for electric vehicles.