Market Overview

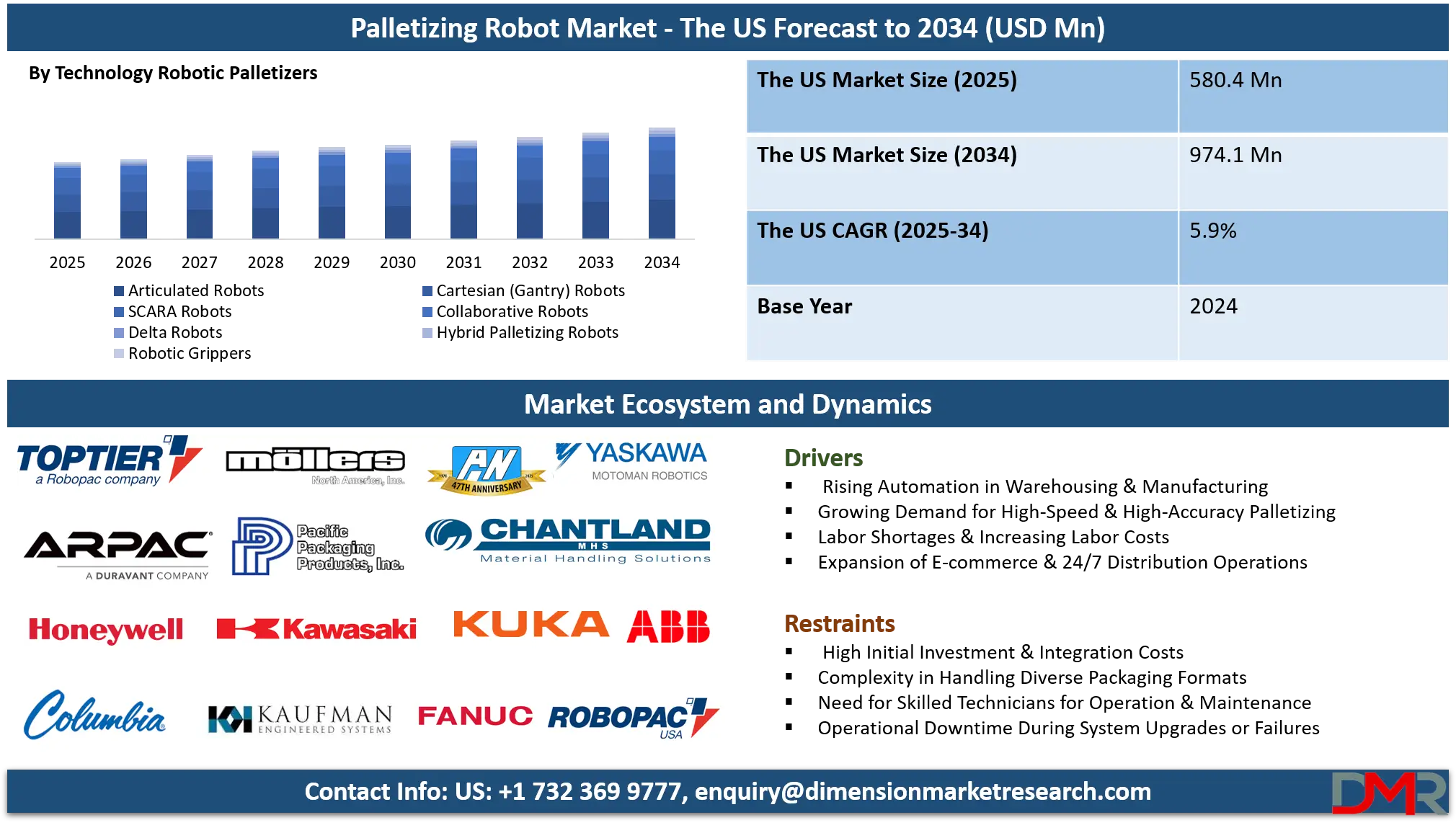

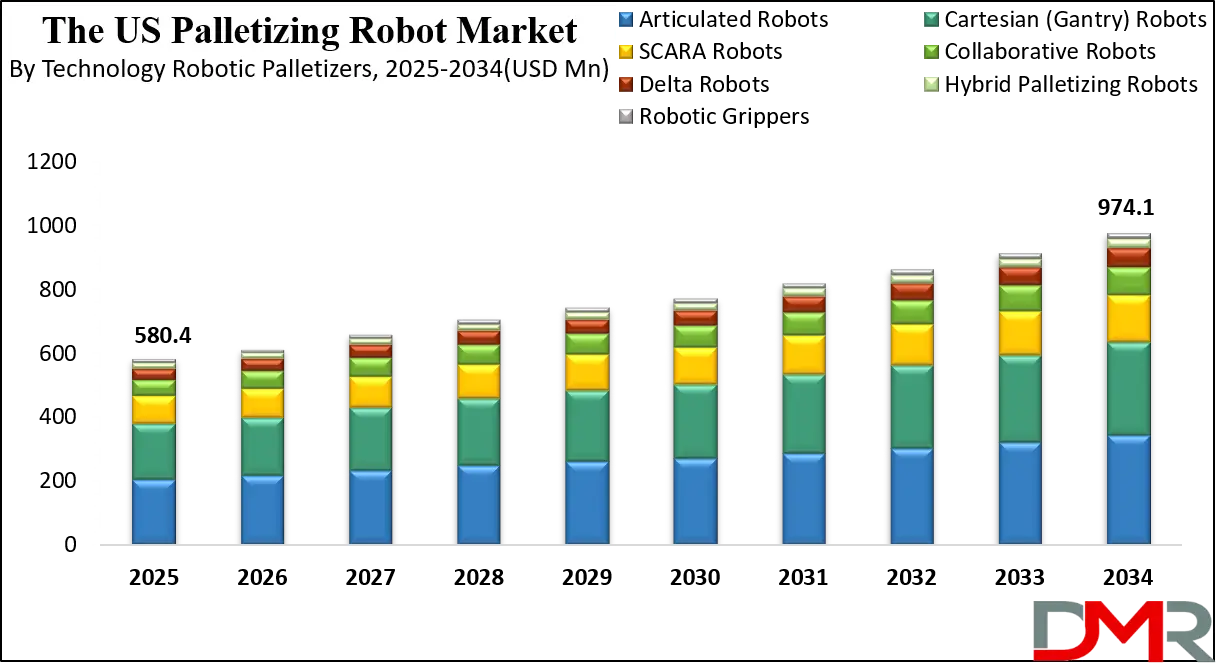

The U.S. Robotic Palletizers Market is projected to be valued at USD 580.4 million in 2025 and is further expected to reach USD 974.1 million by 2034, expanding at a CAGR of 5.9% over the forecast period.

This robust growth is driven by the urgent need for supply chain automation, persistent labor shortages, and the rapid expansion of e-commerce fulfillment across the country. The United States represents one of the world's largest and most dynamic markets for robotic palletizing, fueled by its massive manufacturing base, extensive logistics networks, and significant investments in warehouse automation. As companies face rising labor costs, difficulty filling physically demanding jobs, and increasing consumer expectations for faster delivery, robotic palletizing systems have become critical solutions for improving efficiency, consistency, and scalability in material handling operations.

The U.S. market is characterized by its scale, speed of adoption, and preference for high-throughput systems capable of operating in large distribution centers and manufacturing facilities. Unlike some markets that prioritize precision or flexibility above all else, American operations often emphasize throughput volume, reliability in

24/7 operations, and rapid return on investment.

The growth of omnichannel retail has transformed palletizing requirements, with systems now needing to handle everything from uniform case quantities for store replenishment to mixed-SKU pallets for direct-to-consumer shipping. This diversification of requirements has accelerated innovation, particularly in vision-guided robotics, adaptive end-of-arm tooling, and integrated software systems that optimize pallet patterns in real-time.

Several structural factors are converging to drive adoption. Labor market dynamics are particularly significant, with unemployment in logistics and manufacturing consistently below national averages and turnover rates exceeding 40% annually in some distribution sectors. E-commerce growth continues to outpace traditional retail, creating demand for flexible automation that can handle the "Amazon effect" of infinite SKU variety.

Reshoring initiatives supported by federal legislation like the CHIPS Act and Inflation Reduction Act are driving new manufacturing investments that increasingly incorporate automation from the ground up. Additionally, safety and ergonomic concerns are pushing companies to automate the most injury-prone manual tasks, with palletizing consistently ranking among the top causes of workplace musculoskeletal disorders.

Technologically, the U.S. market is embracing collaborative robotics for smaller operations and retrofits, mobile robotic solutions for flexible deployment, and cloud-connected systems that enable remote monitoring and predictive maintenance. American companies are particularly focused on scalability solutions that can start with a single robot and expand to coordinated fleets and integration with existing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms. The competitive landscape features both global robotic giants and specialized American system integrators who understand the unique scale and operational requirements of U.S. distribution networks.

The US Robotic Palletizers Market: Key Takeaways

- Exceptional Growth Trajectory: The U.S. market is projected to grow from USD 580.4 million in 2025 to USD 974.1 million by 2034, achieving a CAGR of 5.9% among the highest rates globally for industrial robotics segments, reflecting rapid automation adoption across supply chains.

- E-commerce as Primary Accelerator: The Logistics & Warehousing sector represents the fastest-growing end-user segment, expanding at over high growth rate, driven by massive investments in fulfillment center automation to handle parcel volume growth and same-day delivery expectations.

- Collaborative Robotics for SME Adoption: Collaborative Robots (Cobots) are experiencing explosive growth, as they enable small and medium-sized manufacturers and distributors to automate palletizing without extensive safety fencing or specialized programming staff.

- Food & Beverage Dominance Continues: The Food & Beverage industry remains the largest end-user, accounting 30.0% of the market, driven by high-volume production, stringent hygiene requirements, and the need for handling diverse packaging formats from cans to flexible pouches.

- Medium Payload Systems Lead: Robots with 101–500 kg capacity capture the largest share as they optimally balance speed and strength for the most common palletizing applications, full cases of consumer goods, beverage multipacks, and packaged food items.

The US Robotic Palletizers Market: Use Cases

- E-commerce Fulfillment Center Parcel Sortation: Major logistics providers and retailers deploy grids of robotic palletizers in fulfillment centers to sort and stack thousands of different-sized parcels onto outbound pallets. A single facility may process over 100,000 parcels daily, with robots working alongside automated conveyors and sortation systems.

- Beverage Production Line Integration: Large breweries and soft drink manufacturers implement high-speed delta or articulated robots that palletize bottles, cans, and multipacks directly from production lines at rates exceeding 2,000 units per minute.

- Food Processing Plant Mixed-Pallet Building: National food manufacturers utilize robotic palletizers with advanced EOAT and vision systems to build store-ready mixed pallets containing various product types (cereal boxes, canned goods, snack bags) according to specific retail chain requirements.

- Pharmaceutical Distribution Center Compliance Palletizing: Pharmaceutical distributors employ robotic systems in temperature-controlled environments to palletize cases of medications while maintaining strict serialization data integrity per DSCSA requirements.

- Manufacturing Plant Raw Material Handling: Automotive parts suppliers and industrial manufacturers use heavy-payload robotic palletizers to handle raw materials (steel coils, plastic resins in bags, component totes) and finished goods.

The US Robotic Palletizers Market: Stats & Facts

U.S. Government & Industry Data Sources

- U.S. Bureau of Labor Statistics (BLS): Reports that material handling laborers experience one of the highest injury rates in manufacturing, with over 30,000 cases annually involving strains, sprains, and tears from manual lifting, a key driver for automation.

- U.S. Census Bureau: E-commerce sales data shows consistent double-digit annual growth, reaching over USD 1.1 trillion in 2024, directly correlating with warehouse automation investments, including robotic palletizing.

- Association for Advancing Automation (A3): U.S. robotics market data indicates North America installed approximately 44,000 industrial robots in 2024, with material handling applications representing the largest category at 38% of installations.

- Material Handling Institute (MHI): Annual industry reports show that over 60% of U.S. companies are increasing automation investments, with palletizing among the top three targeted applications for robotics implementation.

- U.S. Department of Commerce: Manufacturing data indicates that reshoring initiatives have brought back approximately 350,000 jobs since 2020, with new facilities typically incorporating higher levels of automation than previous generations of plants.

- Occupational Safety and Health Administration (OSHA): Regulations on manual material handling (1910.176) and ergonomics guidelines create compliance incentives for automating repetitive lifting tasks like palletizing.

Economic & Market Context

- The U.S. warehousing and storage sector employs over 1.9 million workers with an average turnover rate exceeding 40% annually, creating severe labor availability challenges, driving automation adoption.

- Average wages for material handling workers have increased over 25% since 2020, improving the ROI calculation for robotic palletizing systems, which typically achieve payback in 1.5 to 3 years.

- The U.S. has over 20,000 warehouses larger than 100,000 square feet, with many built in the last five years specifically designed for automation integration.

Regulatory & Policy Influences

- Section 179 tax deductions allow businesses to deduct the full purchase price of qualifying equipment, including robotic palletizers, in the year placed in service, significantly improving ROI.

- Inflation Reduction Act manufacturing credits support automation investments in clean energy and semiconductor sectors.

- OSHA's National Emphasis Program on Warehousing (initiated 2023) has increased inspections and citations in manual material handling operations, accelerating safety-driven automation.

The US Robotic Palletizers Market: Market Dynamics

Driving Factors in the U.S. Robotic Palletizers Market

Critical Labor Shortages and Rising Employment Costs

The U.S. faces a structural labor crisis in material handling occupations, with warehouse worker turnover often exceeding 100% annually in some markets and persistent unfilled positions despite wage increases of 20-30% since 2020. The physically demanding nature of manual palletizing, combined with irregular shift requirements and seasonal peak demands, makes these positions particularly difficult to staff consistently.

Robotic palletizers provide a reliable, consistent alternative that operates 24/7 without breaks, turnover, or fatigue. Beyond direct labor replacement, they address indirect costs, including recruitment, training, workers' compensation claims from lifting injuries, and productivity losses during staffing gaps. With the U.S. unemployment rate consistently below 4% and demographic trends showing declining workforce participation in manual labor, automation has shifted from efficiency improvement to operational necessity.

E-commerce Revolution and Omnichannel Distribution Demands

The transformation of retail has fundamentally changed palletizing requirements. Where traditional distribution involved full pallets of identical SKUs moving to stores, modern fulfillment requires mixed-SKU pallets for store replenishment, single-item parcels for direct-to-consumer, and everything in between. This variability challenges fixed automation and manual labor alike.

Robotic palletizers with advanced vision systems and AI-driven pattern optimization provide the flexibility to handle this complexity efficiently. The growth of same-day and next-day delivery expectations further pressures operations to accelerate throughput and extend operating hours capabilities where robotics excel. Major e-commerce and logistics companies are making billion-dollar investments in automation, with robotic palletizing as a core component of next-generation fulfillment centers.

Restraints in the U.S. Robotic Palletizers Market

Capital Intensity and Financing Challenges

While robotic system costs have decreased approximately 30% over the past decade, complete palletizing workcells including robot, EOAT, safety systems, conveyors, and integration still represent significant capital investment ranging from USD 75,000 for collaborative systems to over USD 500,000 for high-speed industrial installations.

Small and medium-sized enterprises, which constitute the majority of U.S. manufacturers and distributors, often face capital constraints and lengthy ROI justifications. Traditional financing options may not align with technology refresh cycles, and the technical complexity can make total cost of ownership calculations challenging. This has slowed adoption among smaller operations despite clear operational benefits, creating a market bifurcation between large enterprises with automation budgets and SMEs still relying on manual labor or simpler automation.

Integration Complexity and Legacy System Compatibility

Many U.S. facilities operate with decades-old material handling infrastructure not designed for robotic integration. Retrofitting robotic palletizers into existing operations often requires substantial modifications to conveyor layouts, facility electrical systems, and operational workflows. Integration with legacy Warehouse Management Systems (WMS) and Manufacturing Execution Systems (MES) can be particularly challenging, requiring custom interfaces and data mapping.

The diversity of packaging formats across American consumer goods, ranging from rigid boxes to flexible pouches, bags, and irregular shapes, demands sophisticated EOAT solutions that may require custom engineering. These integration challenges extend implementation timelines, increase project costs, and require specialized expertise that may not be available in-house, creating dependency on system integrators.

Opportunities in the U.S. Robotic Palletizers Market

Robotics-as-a-Service (RaaS) and Flexible Business Models

Emerging subscription-based models are transforming market accessibility, particularly for small and medium enterprises. RaaS offerings provide robotic palletizing capability with minimal upfront investment, typically including installation, maintenance, and software updates for a monthly fee based on usage (per-pallet or per-hour).

This shifts the financial model from capital expenditure to operational expense, aligns vendor incentives with system performance (uptime directly affects their revenue), and provides predictable budgeting. Additionally, modular palletizing systems that can be reconfigured for different products or production lines offer flexibility valuable in contract manufacturing and seasonal operations. These innovative business models, combined with cloud-based monitoring and remote support, are lowering adoption barriers and expanding the addressable market.

Artificial Intelligence and Machine Learning Integration

The convergence of robotics with advanced Artificial Intelligence creates significant value-creation opportunities beyond basic automation. Machine learning algorithms can optimize pallet patterns in real-time based on package dimensions, weight distribution, and destination requirements, improving trailer cube utilization by 10-20%.

Computer vision systems with p learndeeing can inspect packages for damage, verify labels, and identify improper orientation before palletizing. Predictive maintenance algorithms analyze robot sensor data to forecast component failures before they cause downtime. Natural language interfaces allow non-technical operators to program robots through voice or simple commands. American technology companies are particularly well-positioned to lead in these software-driven enhancements, creating differentiation beyond mechanical robotics capabilities.

Trends in the U.S. Robotic Palletizers Market

Mobile Robotic Palletizing and Flexible Automation

While most palletizing robots remain fixed installations, there is a growing deployment of Autonomous Mobile Robots (AMRs) with integrated palletizing capabilities. These systems combine mobility with robotic manipulation, allowing them to pick products from multiple locations, build pallets at optimal stations, and transport finished pallets to staging areas, all without fixed conveyor infrastructure.

This is particularly valuable for operations with fluctuating layouts, seasonal peak demands, or multi-building facilities. Companies like Amazon are deploying mobile manipulation systems that can be dynamically reassigned throughout fulfillment centers based on real-time demand patterns. This trend toward flexible, infrastructure-light automation aligns with the need for scalable operations that can adapt quickly to changing business requirements.

Sustainable Packaging and Load Optimization

Environmental concerns and economic pressures are driving focus on packaging optimization, where robotic palletizing plays a crucial role. Advanced pattern generation software minimizes void space in pallets, reducing the need for filler materials and enabling more efficient trailer loading (directly reducing transportation costs and emissions). Robots can handle alternative packaging formats like biodegradable materials or reusable containers that may be more fragile or irregular than traditional corrugated. Some systems integrate with packaging equipment to recommend optimal case sizes based on pallet patterns, reducing material waste.

Additionally, robotic depalletizing systems are increasingly used in reverse logistics to efficiently handle returned goods for restocking or recycling. These sustainability applications provide both environmental benefits and cost savings, creating compelling business cases.

The US Robotic Palletizers Market: Research Scope and Analysis

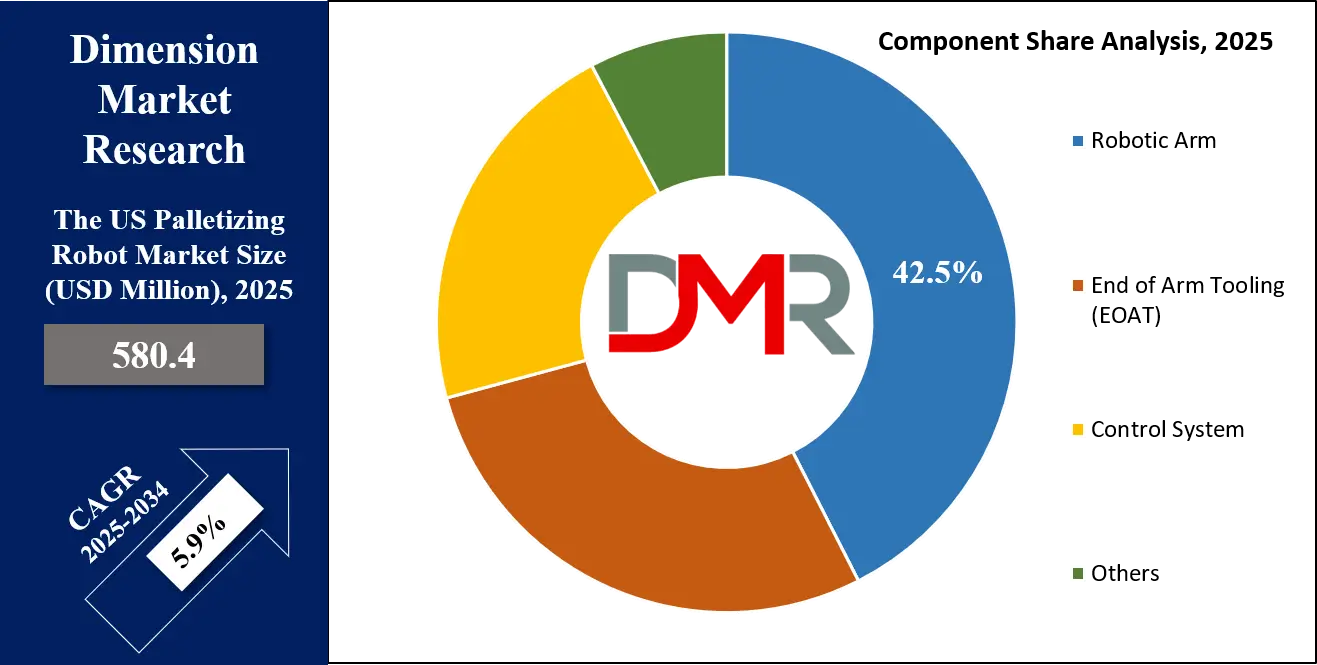

By Component Analysis

Robotic Arms are projected to constitute the core mechanical systems, with articulated (6-axis) robots dominating complex palletizing applications requiring dexterity to handle multiple package types and build stable mixed pallets. In the U.S. market, there is a strong preference for high-speed models capable of sustained operation in 24/7 distribution environments, with emphasis on reliability and minimal maintenance requirements.

American manufacturers and integrators often prioritize robust construction suitable for industrial environments over lightweight designs, with particular attention to sealed components for washdown applications in food processing. The trend is toward easier programming interfaces with graphical environments that reduce dependency on specialized programmers, and standardized connectivity for integration with broader automation systems.

End-of-arm Arm Tooling (EOAT) represents a critical value segment where most application-specific engineering occurs. The diversity of American packaging formats drives demand for sophisticated EOAT solutions. Vacuum grippers dominate for boxes and flat items, with innovations in energy-efficient vacuum generators and adaptive suction cup arrays that conform to irregular surfaces. Mechanical grippers using fingers or clamps handle bags, pouches, and unstable items, with force feedback ensuring a secure grip without damage.

Magnetic grippers serve niche industrial applications. A key trend is quick-change systems allowing automatic tool switching for operations handling multiple product types, and integrated sensors providing grip confirmation and tool health monitoring. U.S. EOAT manufacturers emphasize durability for high-cycle operations and serviceability with readily available replacement parts.

Control Systems have evolved from proprietary robot controllers to open, network-integrated platforms that coordinate multiple automation components. Modern U.S. systems emphasize integration capabilities with common Warehouse Management Systems (like Manhattan, Blue Yonder), cloud connectivity for remote monitoring and software updates, and cybersecurity features protecting industrial networks.

There is growing adoption of PC-based controls running standardized operating systems rather than proprietary hardware, facilitating integration with other automation equipment and IT systems. Safety-rated controllers enable collaborative applications by monitoring forces and speeds to ensure safe human interaction, with particular attention to U.S. safety standards.

By Technology Robotic Palletizers Analysis

Articulated Robots with 6 degrees of freedom are poised to represent the most versatile palletizing solution, capable of handling complex patterns, multiple incoming lines, and varied package types within a single work envelope. Their anthropomorphic design allows them to reach over, under, and around obstacles, making them ideal for retrofitting into existing production lines with space constraints.

In the U.S., articulated robots dominate applications requiring handling of multiple package types, building mixed-SKU pallets, and integration with other automation equipment. American users particularly value models with extended reach for large pallet patterns and high payload capacity for handling heavy cases.

Cartesian/Gantry Robots provide exceptional precision and stability for heavy payload applications, with linear motion along X, Y, and Z axes. They excel in applications requiring precise placement of heavy loads (drums, IBCs, automotive parts) or covering large work areas with multiple infeed conveyors. U.S. implementations often feature modular designs allowing customized work envelope dimensions and hybrid configurations combining linear axes with rotary wrist units. They are particularly common in automotive manufacturing for palletizing large components and in heavy industry for handling bulky materials.

SCARA Robots offer exceptional speed for selective palletizing applications where packages arrive in consistent orientation. Their rigid vertical structure provides high stiffness for precise vertical placement, making them ideal for high-speed stacking of uniform packages in pharmaceuticals, electronics, and cosmetics. In the U.S., SCARA robots are commonly deployed in cleanroom environments and applications requiring precise, repetitive placement. They are increasingly available with collaborative features for safe operation alongside human workers.

Collaborative Robots (Cobots) represent the fastest-growing segment, designed to work alongside humans without traditional safety fencing. U.S. adoption is particularly strong in small and medium enterprises, applications requiring frequent changeovers, and operations where space constraints prevent safety fencing. American cobot manufacturers emphasize intuitive programming interfaces (often hand-guiding or tablet-based), compliance with U.S. safety standards, and quick deployment with minimal integration engineering. Their growth is driven by labor shortages in smaller operations and the need for flexible automation that can be easily reconfigured.

By Payload Capacity Analysis

Low Payload Systems (up to 100 kg) are expected to handle the majority of parcel, case, and bag palletizing applications. This segment is experiencing rapid growth due to e-commerce fulfillment expansion, pharmaceutical packaging, and consumer goods manufacturing. Robots in this range emphasize speed and flexibility over brute force, with advanced vision systems to handle diverse package sizes and shapes. In the U.S., this segment shows the strongest adoption of collaborative robots and mobile manipulation systems, as the lower weight allows for more flexible deployment options. Applications include small parcel sorting, electronics packaging, and cosmetics palletizing.

Medium Payload Systems (101–500 kg) represent the core of industrial palletizing for manufacturing sectors. This range handles full cases of packaged goods, bags of raw materials, and medium-sized industrial components. In the U.S. market, these systems dominate in food & beverage, consumer packaged goods, and general manufacturing. Robots in this category balance speed with strength, often featuring enhanced rigidity for precise heavy placement and advanced path optimization to minimize cycle times while handling substantial mass. American manufacturers prioritize reliability and uptime in this segment, with designs optimized for continuous operation in high-volume environments.

High Payload Systems (above 500 kg) serve heavy industry applications, including chemical drums, building materials, automotive components, and metal products. These robust systems prioritize stability and precision under load over speed, often incorporating dual-arm configurations for balanced handling of asymmetric loads. Safety is paramount, with redundant braking systems and load monitoring. While representing smaller unit volumes, high-payload systems command premium pricing and require sophisticated application engineering. In the U.S., these systems are heavily deployed in chemical processing, metal fabrication, and heavy equipment manufacturing.

By Application Analysis

Case Palletizing is expected to be the largest application segment, encompassing corrugated boxes of finished goods across all manufacturing sectors. U.S. implementations increasingly emphasize mixed-case palletizing for retail distribution, requiring sophisticated pattern generation algorithms that consider case dimensions, weight distribution, and store aisle placement sequences. Advanced systems incorporate weight checking and label verification during the palletizing process to ensure shipping accuracy. The growth of store-ready pallets (merchandised displays) represents a specialized subset requiring precise placement for optimal retail presentation.

Bag Palletizing handles flexible packaging of powders, granules, agricultural products, and chemicals. This challenging application requires a specialized EOAT that can securely grip bags without damage while accommodating bag shape deformation. U.S. solutions often feature bag flattening and squaring systems upstream of the robot to create consistent stacking surfaces, and pattern stabilization techniques (interlocking patterns, adhesive application) to prevent load shifting during transport. This application is particularly strong in pet food, agricultural products, and building materials.

Bottle & Can Palletizing serves the beverage, dairy, and personal care industries with extremely high-speed requirements. U.S. systems excel in full-layer handling using vacuum head arrays that pick entire layers simultaneously, achieving speeds exceeding 2,000 containers per minute. Integration with upstream filling/capping lines and downstream stretch wrapping is seamless, with American packaging machinery manufacturers offering complete turnkey lines. This application shows particularly high automation rates due to the volume and physical demands of manual handling.

By End-user Analysis

Food & Beverage is expected to be the largest end-user segment, driven by high-volume production, stringent hygiene requirements, and the need for handling diverse packaging formats. U.S. food processors value systems that can handle delicate products without damage, accommodate quick changeovers between different products, and operate in washdown environments. Particular growth areas include fresh produce, prepared meals, and beverage multipacks. Traceability from production lot to pallet is increasingly important for recall management and quality control.

Logistics & Warehousing represents the fastest-growing segment, driven by e-commerce expansion and labor shortages. Requirements include extreme flexibility to handle infinite SKU variations, integration with warehouse management systems, 24/7 operation reliability, and efficient use of expensive real estate. Major logistics providers are implementing robotic palletizing grids with multiple robots serving shared work areas and autonomous mobile palletizing systems that combine transport and stacking. This segment shows the strongest adoption of AI and machine learning for optimization.

Pharmaceutical & Healthcare demands precision handling, cleanroom compatibility, and full serialization integration per DSCSA requirements. Systems must accommodate small batch sizes with frequent changeovers and provide documented process validation. The growth of biologics and specialty medications with specific handling requirements is driving innovation in this segment. Collaborative robots are gaining traction for handling high-value, low-volume products.

Consumer Goods encompasses diverse products from electronics to household items. Requirements include handling multiple SKUs simultaneously (for e-commerce fulfillment), damage-free handling of retail-ready packaging, and efficient space utilization in shipping containers. American consumer goods manufacturers are adopting mobile robotic solutions that can be reconfigured for different product lines and cloud-connected systems for performance monitoring across multiple facilities.

Chemical & Industrial Products prioritizes safety (handling hazardous materials), heavy payload capability, and compatibility with various container types (drums, bags, IBCs). Systems often operate in harsh environments requiring corrosion-resistant construction and explosion-proof ratings for volatile substances. This segment shows steady growth tied to general industrial activity and reshoring initiatives.

The Palletizing Robot Market Report is segmented based on the following:

By Component

- Robotic Arm

- End of Arm Tooling (EOAT)

- Control System

- Others

By Technology Robotic Palletizers

- Articulated Robots

- Cartesian (Gantry) Robots

- SCARA Robots (Selective Compliance Assembly Robot Arm)

- Collaborative Robots (Cobots)

- Delta Robots

- Hybrid Palletizing Robots

- Robotic Grippers

- Vacuum Grippers

- Magnetic Grippers

- Mechanical Grippers

By Payload Capacity

- Low Payload (Up to 100 kg)

- Medium Payload (101–500 kg)

- High Payload (Above 500 kg)

By Application

- Case Palletizing

- Bag Palletizing

- Bottle Palletizing

- Drum Palletizing

By End User

- Food & Beverage

- Pharmaceutical

- Consumer Goods

- Chemical

- Logistics & Warehousing

Impact of Artificial Intelligence on The US Robotic Palletizers Market

- AI-Optimized Load Building: Machine learning algorithms analyze dimensions, weights, and center of gravity for mixed SKUs to generate optimal stacking patterns that maximize trailer cube utilization (often improving by 15-20%), minimize packaging materials, and ensure load stability during transport. Systems continuously learn from shipping data, adapting patterns for specific carriers, routes, and vehicle types common in U.S. logistics networks.

- Predictive Quality Assurance: Advanced computer vision using deep learning inspects packages for damage, correct labeling, and proper sealing during the palletizing process. AI identifies subtle defects (crushed corners, torn labels, improper closures) that human operators might miss and can automatically reject damaged items or flag pallets for manual inspection. This is particularly valuable in regulated industries like pharmaceuticals and food, where quality compliance is critical.

- Adaptive Gripping Intelligence: AI enables robots to adjust gripping strategy in real-time based on package material, weight distribution, and orientation detected through sensors. For delicate items (electronics, baked goods) or variable items (deforming bags), AI modulates vacuum pressure or mechanical grip force to prevent damage while ensuring secure handling. Systems learn optimal approaches for different package types, reducing product damage rates significantly.

- Predictive Maintenance & Performance Optimization: AI algorithms analyze data from robot sensors (motor currents, vibration patterns, temperature readings, cycle times) to predict component failures before they cause unplanned downtime. Systems can schedule maintenance during planned breaks, automatically order replacement parts, and adjust robot parameters to extend the life of wearing components. This maximizes uptime in high-utilization U.S. distribution and manufacturing environments where downtime costs thousands per hour.

- Dynamic Workcell Coordination: In multi-robot palletizing cells (common in large U.S. fulfillment centers), AI coordinates multiple robots to avoid collisions, balance workload, and optimize overall throughput. Systems dynamically reassign tasks based on real-time line speeds, robot availability, and order priorities. AI can also optimize energy consumption by managing robot acceleration profiles and coordinating with facility energy management systems, particularly valuable in regions with time-of-use electricity pricing.

Competitive Landscape

The U.S. robotic palletizers market features a dynamic, multi-layered competitive ecosystem with global robotic OEMs, specialized American system integrators, traditional packaging machinery companies expanding into robotics, and innovative startups. The market is characterized by rapid technological evolution, emphasis on scalability and throughput, and growing importance of software and services alongside hardware.

Global Robotic OEMs, including FANUC America, ABB Robotics U.S., Yaskawa America (Motoman), and KUKA Robotics, dominate the robotic arm supply, offering palletizing-specific models with optimized speed and payload characteristics. These companies compete on robot performance, reliability in 24/7 operations, nationwide service networks, and integration partnerships. They have established strong positions through direct sales to large enterprises and partnerships with system integrators for customized solutions.

Specialized Palletizing Solution Providers like Columbia/Okura, Brenton Engineering, and Arrowhead Systems offer turnkey palletizing systems with deep application expertise in specific industries. These companies differentiate through complete system integration, proprietary software for pattern generation, industry-specific compliance (USDA, FDA, OSHA), and aftermarket support. They often provide more customized solutions than global OEMs, particularly for complex applications.

Traditional Packaging Machinery Manufacturers such as ProMach, Barry-Wehmiller, and Bradman Lake Group have expanded into robotic palletizing as part of complete packaging line offerings, leveraging their existing customer relationships and process knowledge in specific verticals like food & beverage and pharmaceuticals.

Some of the prominent players in the US Palletizing Robot Market are:

- FANUC America

- ABB Robotics

- KUKA Robotics

- Yaskawa (Motoman)

- Kawasaki Robotics

- Schneider Packaging Equipment

- Honeywell Intelligrated

- Dematic

- TopTier (Robopac)

- Robopac USA

- Columbia Machine

- Kaufman Engineered Systems

- Mollers North America

- American-Newlong

- Chantland MHS

- Pacific Packaging Products

- Arpac LLC

- Premier Tech

- Okura Yusoki

- Concetti S.p.A

- Other Key Players

Recent Developments

- March 2025: Amazon announced deployment of its next-generation "PalletSquad" robotic systems across 30 U.S. fulfillment centers, featuring AI-driven mixed-SKU palletizing that improves trailer cube utilization by 22% and reduces packaging damage by 65% compared to previous systems.

- February 2025: FANUC America launched its "CRX Palletizing Series" specifically designed for U.S. SMEs, featuring collaborative robots with integrated vision, simplified programming via tablet interface, and subscription-based financing options starting at USD 5 per hour of operation.

- December 2024: The U.S. Department of Energy awarded USD 25 million in grants to robotics companies developing energy-efficient palletizing systems, with projects focusing on regenerative braking, optimized motion profiles, and integration with facility energy management systems.

- October 2024: PepsiCo completed a USD 150 million automation upgrade at its largest U.S. beverage plant, installing a fully robotic palletizing system that handles 4,000 bottles per minute while reducing energy consumption by 30% through advanced motion control and heat recovery systems.

- July 2024: RightHand Robotics secured USD 45 million in Series D funding to expand its AI-powered piece-picking and palletizing solutions, with particular focus on pharmaceutical distribution centers requiring high accuracy and traceability compliance.

- May 2024: OSHA introduced updated guidelines for human-robot collaboration in palletizing operations, clarifying safety requirements for collaborative systems and establishing certification protocols, accelerating cobot adoption in mixed human-robot environments.

- March 2024: Walmart deployed autonomous mobile palletizing robots in 50 regional distribution centers, using AMRs with integrated manipulators to build mixed pallets for store delivery, reducing manual handling by 70% in pilot locations.

- January 2024: ProMach acquired robotics integrator "Automated Solutions" for USD 120 million, expanding its capabilities in turnkey robotic palletizing systems for food and beverage customers, reflecting the industry consolidation trend.

- November 2023: The U.S. Food and Drug Administration (FDA) approved the use of robotic palletizing with continuous vision inspection for pharmaceutical serialization, allowing automated verification of unique identifiers during pallet building, a breakthrough for compliance automation.

- September 2023: FedEx Ground implemented robotic parcel palletizing systems at 15 major hubs, utilizing 3D vision and AI pattern optimization to handle peak season volumes exceeding 500,000 parcels daily per facility without additional seasonal labor.

- June 2023: A consortium of U.S. packaging manufacturers and robotics companies launched the "Sustainable Palletizing Initiative," developing standards for optimized package designs that work efficiently with robotic systems to minimize material waste.

- April 2023: Tesla revealed its fully automated parts palletizing system at Giga Texas, using custom-designed robots to handle electric vehicle battery components and body panels, achieving 99.8% placement accuracy for just-in-time delivery to assembly lines.

Report Details

| Report Characteristics |

| Market Size (2025) |

USD 580.4 Mn |

| Forecast Value (2034) |

USD 974.1 Mn |

| CAGR (2025–2034) |

5.9% |

| Historical Data |

2019 – 2024 |

| Forecast Data |

2026 – 2034 |

| Base Year |

2024 |

| Estimate Year |

2025 |

| Report Coverage |

Market Revenue Estimation, Market Dynamics, Competitive Landscape, Growth Factors, etc. |

| Segments Covered |

By Component (Robotic Arm, End of Arm Tooling (EOAT), Control System, and Others), By Technology Robotic Palletizers (Articulated Robots, Cartesian (Gantry) Robots, SCARA Robots (Selective Compliance Assembly Robot Arm), Collaborative Robots (Cobots), Delta Robots, Hybrid Palletizing Robots, and Robotic Grippers), By Payload Capacity (Low Payload (Up to 100 kg), Medium Payload (101–500 kg), and High Payload (Above 500 kg)), By Application (Case Palletizing, Bag Palletizing, Bottle Palletizing, and Drum Palletizing), By End User (Food & Beverage, Pharmaceutical, Consumer Goods, Chemical, and Logistics & Warehousing) |

| Regional Coverage |

The US |

| Prominent Players |

FANUC America, ABB Robotics, KUKA Robotics, Yaskawa Motoman, Kawasaki Robotics, Schneider Packaging Equipment, Honeywell Intelligrated, Dematic, TopTier (Robopac), Robopac USA, Columbia Machine, Kaufman Engineered Systems, Mollers North America, American-Newlong, Chantland MHS, Pacific Packaging Products, Arpac LLC, Premier Tech, Okura Yusoki, Concetti S.p.A., and Other Key Players |

| Purchase Options |

We have three licenses to opt for: Single User License (Limited to 1 user), Multi-User License (Up to 5 Users), and Corporate Use License (Unlimited User) along with free report customization equivalent to 0 analyst working days, 3 analysts working days, and 5 analysts working days respectively. |

Frequently Asked Questions

The U.S. Robotic Palletizers Market size is estimated to have a value of USD 580.4 million in 2025 and is expected to reach USD 974.1 million by the end of 2034.

The market is growing at a Compound Annual Growth Rate (CAGR) of 5.9 percent over the forecast period from 2025 to 2034.

The market features global robotic OEMs (FANUC, ABB, Yaskawa), specialized palletizing solution providers (Columbia/Okura, Brenton), traditional packaging machinery companies expanding into robotics (ProMach, Barry-Wehmiller), and innovative startups focusing on AI and software solutions.